Exploring Automotive Wiring Connector Types

Automotive electrical connectors types are crucial in car systems. They ensure that electrical connections function properly, contributing to the safe operation of the vehicle. New cars typically contain around 40 harnesses, 700 connectors, and over 3,000 wires, highlighting the significance of understanding various car connectors. There are nearly 100 types of connectors commonly utilized in standard automobiles, reflecting the increasing use of electronic components in vehicles. With advancing technology, the demand for specialized connectors continues to grow, making them essential components in automotive design.

Overview of Automotive Wiring Connectors

Definition and Purpose

What are wiring connectors?

Wiring connectors are key parts in car systems. They help connect and disconnect wires in cars. These connectors have different shapes and sizes for various needs. They link wires, sensors, switches, and modules to help them work together.

Why are they essential in automotive systems?

Car connectors are vital for keeping cars working safely. They help parts inside the car talk to each other and outside networks too. Good connections make body control, safety, security, and entertainment systems work better. As cars get more complex with electronics, these connectors become even more important.

Basic Components of Connectors

Pins and Sockets

Pins and sockets are the main parts of a connector. They join wires together electrically. Pins fit into sockets to make a circuit complete. This setup keeps the connection strong so it doesn't fail easily. The pins' quality affects how well the whole system works.

Housing and Insulation

A connector's housing gives support and protects pins and sockets. It keeps out water, dust, and shakes from outside. Insulation stops electrical shorts for safety reasons. Housing with insulation makes sure connectors last long in tough car conditions.

Types of Car Wiring Connectors

Blade Connectors

What They Are and Where They're Used

Blade connectors look flat like a blade. They are important in car wiring. You stick them into a matching slot to connect things. They are great for quick and safe connections. You can easily unplug them, which is good for parts you fix or change often. Blade connectors are used in car lights, fuse boxes, and other electric parts.

Who Makes Them

Some companies make strong blade connectors. TE Connectivity, Molex, and Delphi are some of these companies. They make sure their connectors work well in cars by following rules for strength and safety.

Ring and Spade Connectors

What They Are and Where They're Used

Ring connectors have round ends that fit over bolts or studs for tight connections. Spade connectors have forked ends that are easy to attach or remove. Both types help with battery links, grounding wires, and places needing strong connections.

Who Makes Them

3M, Panduit, and Ancor make ring and spade connectors known for being tough and simple to use. These companies focus on making products that last long even in rough car conditions.

Butt Connectors

What They Are and Where They're Used

Butt connectors join two wires end-to-end securely. They're useful when you need to splice wires together. Their design keeps the connection safe from shaking or bad weather in cars.

Who Makes Them

Gardner Bender, Ideal Industries, and Klein Tools make many kinds of butt connectors for cars. These makers care about quality so their products meet the needs of today's cars.

Other Types of Car Connectors

Pigtail Connectors

Pigtail connectors are important in cars. They link wires to parts for smooth electricity flow. These connectors have short wires attached, making them easy to install. Mechanics use them when direct links are hard. Their design is flexible and simple, so they are often used in cars.

Crimp Connectors

Crimp connectors make strong wire connections in cars. They squeeze a metal sleeve around the wire for a tight fit. This way, no soldering is needed, saving time and tools. Crimp connectors handle shakes and tough conditions well, perfect for cars. They stay connected even during bumpy rides.

Multi-pin Sealed Connectors

Multi-pin sealed connectors solve complex car wiring needs. They have many pins for connecting several wires at once. The seal keeps out water and dirt, working well in bad weather. These connectors are key in modern cars with advanced systems needing reliable links.

Choosing the right car wiring connectors is important. You need to think about many things to make sure they fit the car's needs and work well for a long time.

Electrical Needs

Current and Voltage Ratings

It's key to know how much electricity connectors can handle. They should not get too hot or stop working. Makers build connectors for certain electricity levels, so they work safely. For example, in smart car systems, connectors must manage strong signals.

Environmental Factors

Car connectors face tough weather. They need to keep out water, dirt, and handle temperature changes. Sealed connectors protect against these problems and last longer. In cars, they must also deal with different signal types because they control important parts like airbags.

Mechanical Needs

Strength and Material

Strength matters when picking connectors. They have to take hits and shakes in cars. Strong materials help them last longer. As cars use more electronics, we need stronger connectors to stop failures in key parts.

Easy Setup

Setting up should be simple with good connectors. They should connect fast without mistakes. Features like crimping make setup easier and quicker. Easy-to-install connectors help build and fix cars faster.

Jussi Takaneva from JAE says that small-sized and high-frequency connectors are vital for new car tech like smart systems.

By thinking about these needs, makers can pick the best connectors, making cars work better and safer.

Picking the right car wiring connector is very important. It keeps cars safe and working well. Each type of connector has a special job. They help make sure the car's systems are reliable. As technology gets better, we need more special connectors. This shows how important they are in new car designs.

"Car connectors are key parts in vehicles," showing they come in many shapes and sizes for different jobs.

Learning more about these connectors can help us make smart choices. This makes cars work better and stay safe.

See Also

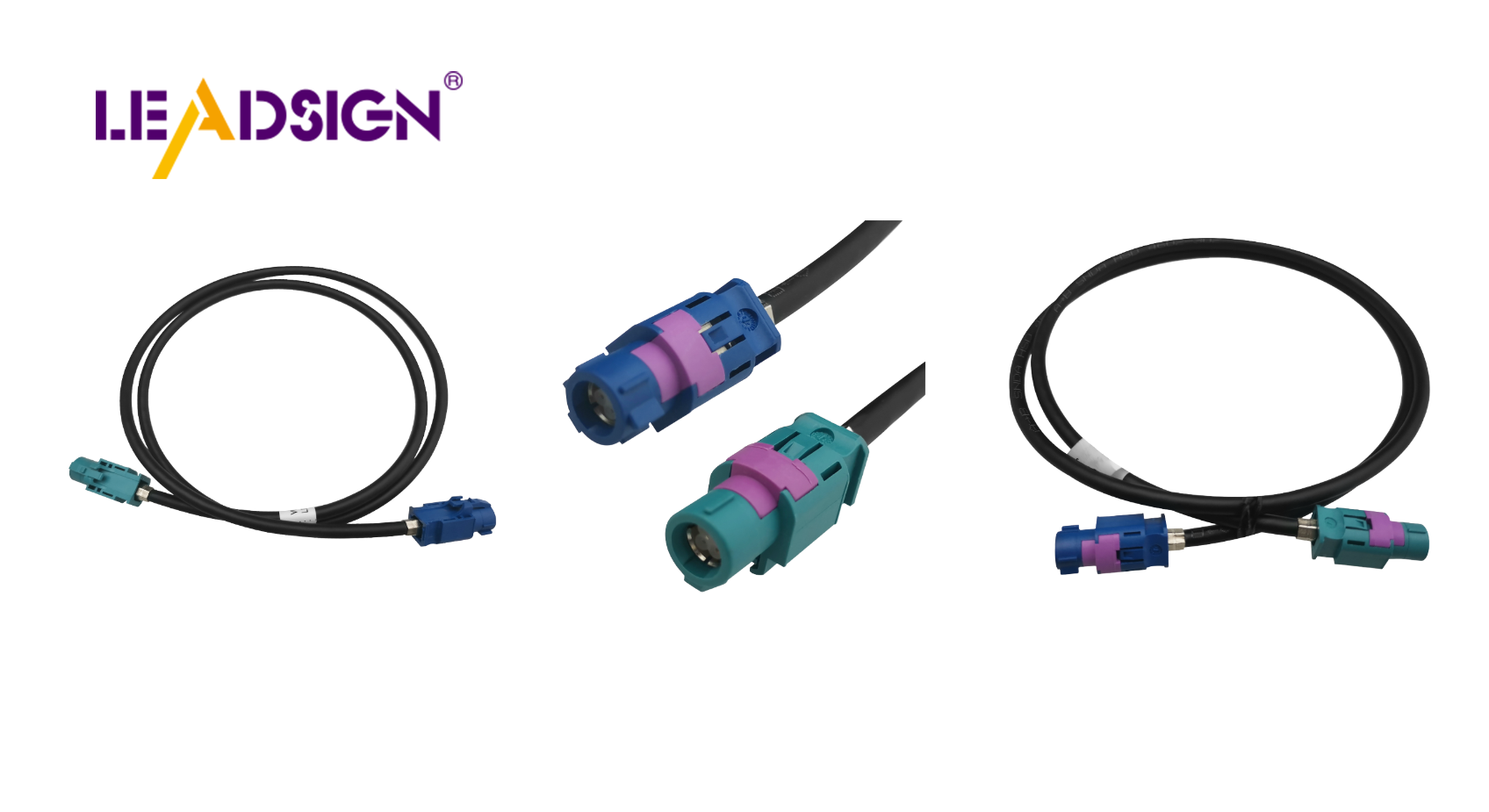

Discovering the Advantages of Fakra Auto Connectors

Essential Guide to HSD Connectors in Auto Sector

Significance of Fakra Auto Connectors in Contemporary Cars