Exploring Automotive Wiring Connector Types

Automotive electrical connectors types are crucial for vehicles. They play a vital role in maintaining efficient electrical connections necessary for the smooth operation of car components. These connectors are designed to withstand challenging conditions such as temperature variations and vibrations. The frequency of connector failures can be influenced by factors like the number of pins and the operating environment. Excessive plugging and unplugging may increase the likelihood of breakage, albeit not excessively. Understanding the various automotive electrical connector types is essential for selecting the appropriate one for each task, ensuring durability and optimal performance.

Overview of Automotive Wiring Connectors

Definition and Purpose

What are Wiring Connectors?

Wiring connectors are key parts in car systems. They help electric power or signals wiring connectors move between vehicle parts. By making a strong connection, they boost the reliability of car circuits. These connectors can handle tough conditions like heat, wetness, and rust, which are common in cars.

Importance in Automotive Systems

In cars, wiring connectors keep electrical connections working well. They shield circuits from harm by shaking, heat, or rust. By giving protection and keeping plug and socket parts lined up right, connectors make sure the equipment stays connected. Using the correct connectors makes repairs last longer, cuts downtime, and makes people happier.

Basic Components of Connectors

Contacts

Contacts are the heart of any connector. They let electricity or signals pass between linked parts. Good contacts clean themselves to keep a steady connection over time. The quality of these contacts is crucial for how well the connector works.

Insulation

Insulation acts as a guard around contacts to stop unwanted electric interactions. It keeps electricity or signals on their set path. Insulation must resist things like temperature changes and wetness to work well.

Housing

The housing protects the inside parts of a connector. It holds contacts and insulation steady for proper alignment and connection. Custom housings offer more dependability by fitting specific needs. They also have seals to better withstand environmental issues.

Types of Automotive Wiring Connectors

Blade Connectors

Features and Uses

Blade connectors are flat and fit into slots. They give a strong connection, perfect for cars. They are simple to use, allowing fast plug-ins. Blade connectors are often in car lights and batteries.

Known Makers

Many companies make good blade connectors. TE Connectivity and Molex are famous for their tough products. They have many types for different car needs.

Pin Connectors

Features and Uses

Pin connectors have pins that go into sockets. Used in cars, they handle many links in small spaces. Found in engines and infotainment systems, they send data well.

Known Makers

Delphi Technologies and Amphenol make pin connectors. They offer choices for various car uses. Their products last long even in bad conditions.

Ring and Spade Connectors

Features and Uses

Ring connectors fit over bolts; spade ones slide under screws. Used in battery terminals, they ensure safe connections.

Known Makers

Companies like Panduit and 3M make ring and spade connectors. Their products meet strict standards, resisting vibration well.

Expert Opinion: "Right connectors give systems needed power, boosting performance."

Knowing about these connector types helps choose the best one for each job, making car systems work better and last longer.

Other Automotive Electrical Connectors Types

Pigtail Connectors

Pigtail connectors are important in cars. They link wires to parts, keeping connections strong. These connectors have short wires attached, making setup easy. With pigtail connectors, fixing or changing parts is simple without messing up all the wiring. This makes them great for keeping car systems working well.

Expert Testimony: "Using the right connectors gives systems the power and signals they need, improving how they work."

Bullet Connectors

Bullet connectors join wires fast and easily. They are perfect for cars because they are reliable. Their shape lets them fit together tightly, staying connected even with shaking or bad weather. Bullet connectors are used in car lights and places where you often unplug things.

Expert Testimony: "The right electrical connectors help systems run smoothly. They make your system smaller and easier to manage."

Scotch Locks

Scotch Locks let you join wires quickly without soldering. They are handy for car fixes and changes. Just put the wires in and close it for a solid connection. This saves time and makes wiring less tricky, especially in tight spots.

Expert Testimony: "Things like water and shaking can harm electrical connections, causing failures. Special connector greases can stop these problems."

Knowing about these connector types helps pick the best one for each job, making sure car systems work well and last long.

Practical Uses and Examples

Use in Different Car Systems

Engine Control Systems

Car wiring connectors are key in engine control systems. They link sensors and parts to the engine control unit (ECU). These links help the ECU get correct data for better engine work. pigtail connectors connect wires to things like oxygen sensors. Checking these connectors often keeps engines running well.

Light Systems

In light systems, connectors give power to headlights and taillights. Blade connectors are easy to use and fit well. They keep lights working right, which is important for safety when driving.

Real-Life Examples

Fast Data Connectors in Car Entertainment Systems

Modern car entertainment needs fast data connectors for sound and video. High-Speed Data (HSD) connectors do this job. They help with USB links and digital electronics, making media play smoothly.

Expert Insight: "Right connectors give systems needed power, boosting performance."

Wire Blocks in Engine Control Units

Wire blocks connect many wires in engine units. They make it easy to manage wires. These blocks ensure all parts get power and signals they need.

Industry Observation: "Water and shaking can hurt connections, causing problems. Special greases can help."

Knowing how car wiring connectors work helps pick the best type for each system, making cars run better and last longer.

Common Questions and Issues

Frequently Asked Questions

How to Pick the Right Connector?

To pick the right connector, know what your car needs. Think about where it will be used and how much power it needs. For example, engine connectors must handle heat and shaking. Make sure it fits with other parts.

What Problems Happen Often?

Connectors can fail from things like water, heat, or shaking. These can cause rust or make them loose or break. Wrong setup can lead to bad connections too. Plugging in and out a lot wears them down over time.

Troubleshooting Tips

Finding Bad Connectors

Look at connectors for cracks or rust to find problems. Use a multimeter to check if they work right. Listen for odd sounds like buzzing that show bad connections.

Care and Upkeep

Taking care of connectors makes them last longer. Clean them often to get rid of dirt that messes up links. Use special grease to stop rust from water. Check that they are tight so they don't shake loose. Regular checks help avoid big fixes later.

Picking the right connector is very important for cars. It helps car parts work well and last long. As technology gets better, connectors get stronger and work better too. They can handle tough car conditions. Knowing about new connector types helps people choose wisely. This makes cars safer and run smoother.

See Also

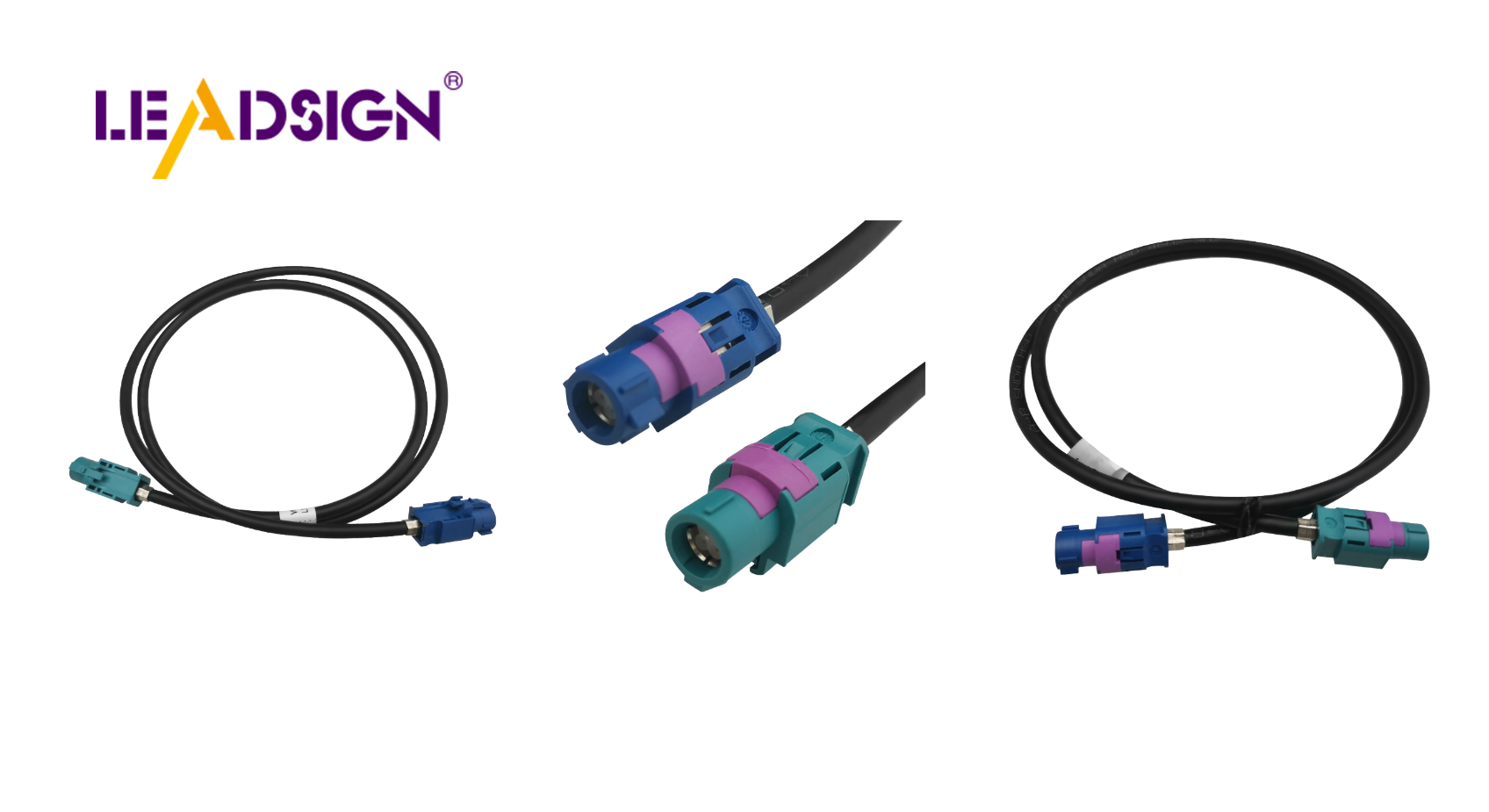

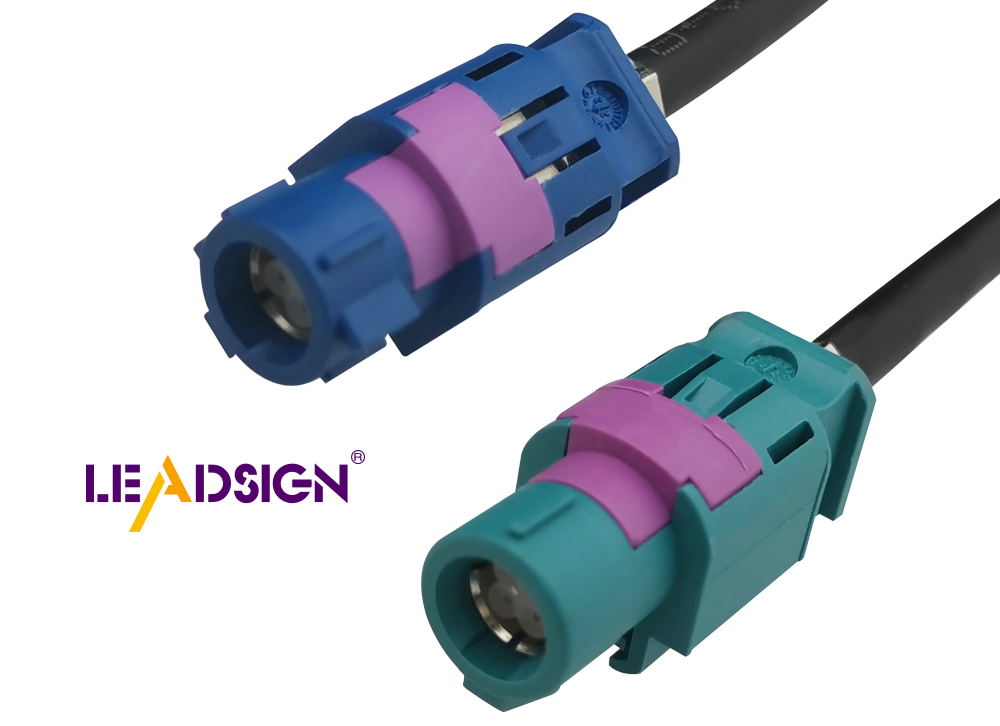

Discovering Advantages of Fakra Car Connectors

Essential Information on HSD Connectors for Cars

The Significance of Fakra Car Connectors in Contemporary Autos