Exploring Automotive Wiring Connector Types

Automotive electrical connectors types play a crucial role in modern vehicles. They ensure seamless communication between various components. Modern vehicles contain close to 40 different harnesses, with up to 700 connectors and more than 3,000 wires. This diversity highlights the evolution of connector types over time. Understanding these connectors is vital for automotive enthusiasts and professionals. It enhances their ability to maintain and repair vehicles effectively. As technology advances, the variety of connectors continues to grow, making it essential to stay informed about the latest developments.

Basics of Automotive Wiring Connectors

Definition and Purpose

What are Wiring Connectors?

Wiring connectors serve as essential components in automotive systems. They join electrical circuits, ensuring seamless communication between various vehicle parts. These connectors come in different shapes and sizes, tailored to meet the specific needs of automotive applications. Automotive electrical connectors offer excellent protection against high temperatures, moisture, and corrosive elements, providing long-lasting performance. Wiring connectors serve as essential

Importance in Automotive Systems

In automotive systems, wiring connectors play a crucial role. They ensure reliable connections between multiple electrical circuits while inhibiting interference. This reliability is vital for the proper functioning of critical vehicle systems, such as engine management and safety features. Deutsch connectors, for instance, are known for their durability and weather resistance, making them ideal for heavy-duty applications.

Key Features

Durability and Reliability

Durability and reliability stand as key features of automotive wiring connectors. Products like Weather Pack connectors are specifically designed for outdoor and under-hood applications, offering excellent resistance to temperature, chemicals, and moisture. These connectors ensure that connections remain intact even in harsh environments, preventing failures that could lead to costly repairs.

Electrical Conductivity

Optimal electrical conductivity is another crucial feature of automotive connectors. Metri-Pack connectors are designed for high-performance applications, ensuring efficient electrical flow in critical areas like fuel injectors and air conditioning systems. This efficiency helps maintain the overall performance and safety of the vehicle. Optimal electrical conductivity

Compatibility with Automotive Standards

Compatibility with automotive standards ensures that connectors meet the rigorous demands of modern vehicles. Many connectors, such as Molex connectors, are available in a wide range of pin configurations and sizes, accommodating various electrical applications. This versatility allows them to integrate seamlessly into different automotive systems, ensuring compliance with industry standards.

Types of Automotive Wiring Connectors

Blade Connectors

Features and Applications

Blade connectors, a common type among automotive electrical connectors types, feature flat conductive blades. These blades fit into a corresponding slot, creating a secure connection. They are widely used in automotive systems due to their simplicity and reliability. Blade connectors often appear in fuse boxes and relay panels, where they facilitate quick and efficient connections. Their design allows for easy insertion and removal, making them ideal for applications requiring frequent disconnection.

Advantages and Disadvantages

Blade connectors offer several advantages. They provide a reliable connection with minimal resistance, ensuring efficient electrical flow. Their flat design allows for compact installations, saving space in crowded automotive systems. However, blade connectors also have some disadvantages. They may become loose over time, especially in environments with constant vibrations. This can lead to intermittent connections, affecting the performance of the vehicle's electrical systems.

Bullet Connectors

Features and Applications

Bullet connectors, another popular choice among automotive electrical connectors types, consist of male and female components that fit together securely. This design allows for easy connection and disconnection, making them suitable for applications where wires need to be frequently connected and disconnected. Bullet connectors are commonly used in lighting systems and other areas where quick changes are necessary. They provide solderless connections for both solid and stranded wires, enhancing their versatility.

Advantages and Disadvantages

The primary advantage of bullet connectors lies in their ease of use. They allow for quick and secure connections without the need for soldering, saving time during installation and maintenance. Additionally, their design ensures a tight fit, reducing the risk of accidental disconnection. However, bullet connectors can sometimes be difficult to disconnect if they become corroded or dirty. Regular maintenance is necessary to ensure their continued reliability.

Pin Connectors

Features and Applications

Pin connectors, a versatile option among automotive electrical connectors types, are used in compression-type terminal blocks. They provide high flexibility and durability, making them suitable for various automotive applications. Pin connectors are often found in engine management systems and other critical areas where reliable connections are essential. Their design allows for the termination of stranded wires, providing a secure and stable connection.

Advantages and Disadvantages

Pin connectors offer several advantages. They provide a strong mechanical connection, ensuring stability even in harsh conditions. Their design allows for easy insertion and removal, facilitating quick repairs and replacements. However, pin connectors may require specialized tools for installation, which can increase the complexity of the process. Despite this, their durability and reliability make them a preferred choice for many automotive applications.

Specialty Connectors

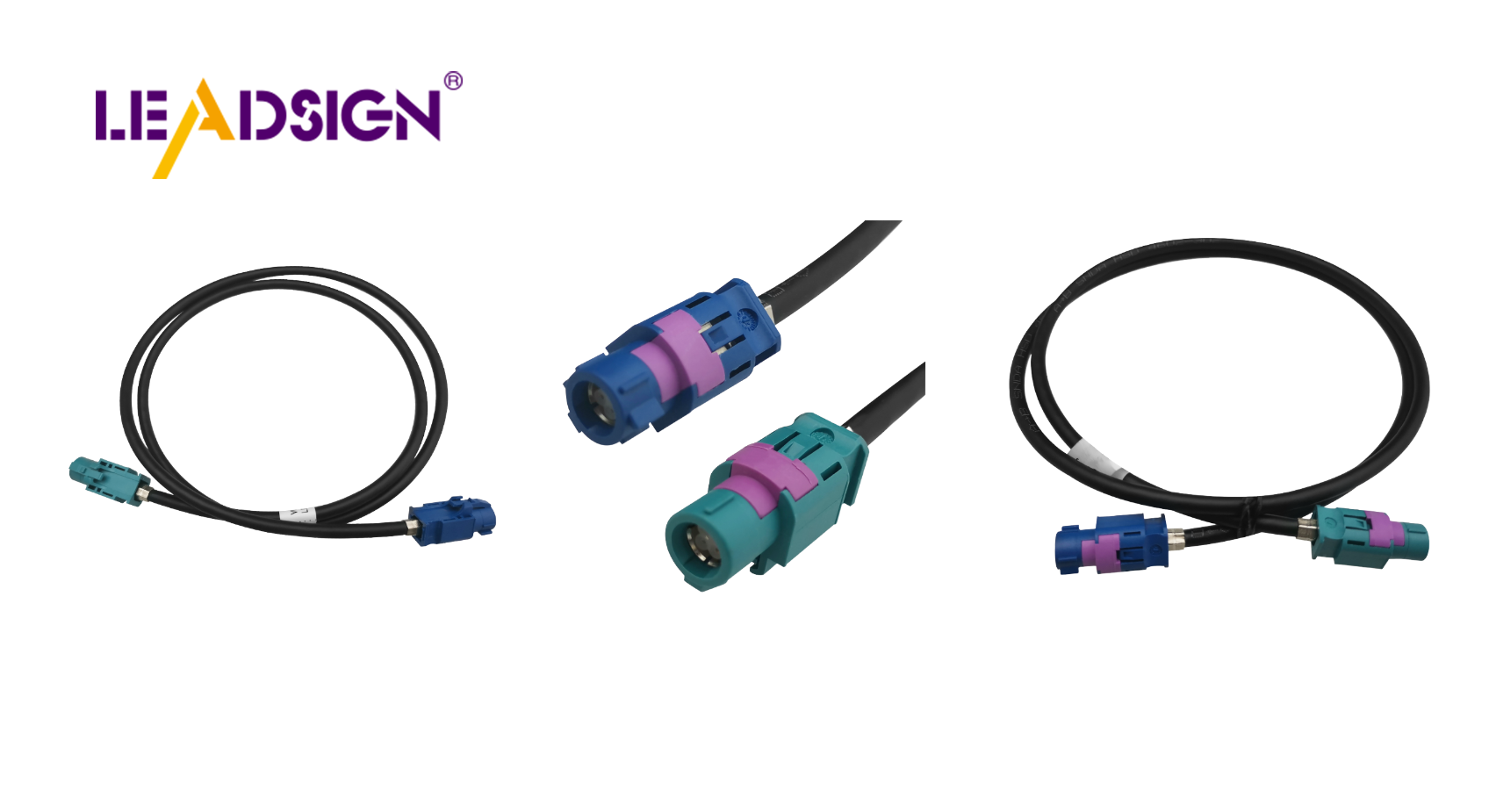

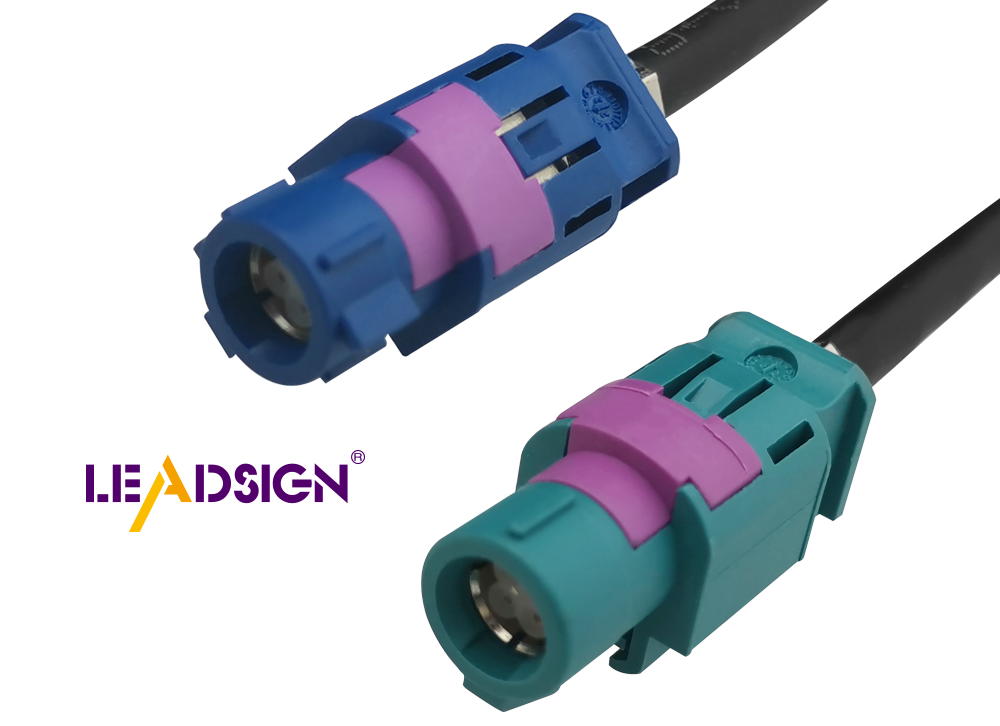

High-Speed Data Connectors

High-speed data connectors represent a significant advancement in automotive electrical connectors types. They facilitate the transmission of high-bit-rate data streams, crucial for modern automotive electronics. These connectors find applications in systems like low-voltage differential signaling (LVDS) cameras, USB connections, and IEEE 1394 applications. Their design supports digital infotainment electronics, digital symmetrical networks, and even telecom industries such as radio base stations.

Key Features:

Primary and Secondary Lock: Ensures secure connections, preventing accidental disconnections.

Crimp Connection: Provides a robust mechanical bond, enhancing durability.

High Cable Retention Force: Maintains connection integrity under stress.

High Coding Efficiency: Different codings on the plastic housing eliminate misconnections.

These connectors play a pivotal role in maintaining the efficiency and reliability of automotive systems. They ensure seamless communication between various components, supporting the vehicle's overall performance.

Sealed Automotive Electrical Connectors

Sealed automotive electrical connectors types are designed to withstand harsh environments. They prevent moisture and contaminants from entering the connection, enhancing durability and reliability. These connectors are essential in areas exposed to extreme conditions, such as under the hood or in outdoor applications.

Applications:

Engine Management Systems: Ensure reliable connections in critical areas.

Safety Features: Maintain the integrity of connections in safety-critical systems.

Outdoor Applications: Provide protection against environmental factors.

Sealed connectors offer several advantages. They provide excellent resistance to temperature, chemicals, and moisture, ensuring long-lasting performance. Their design prevents corrosion and wear, reducing maintenance needs and extending the lifespan of the vehicle's electrical systems.

Installation Techniques and Best Practices

Proper installation of automotive electrical connectors types ensures reliable performance and longevity. This section provides a comprehensive guide to the necessary tools, safety precautions, and step-by-step instructions for connecting various connector types.

Preparation and Tools

Necessary Tools for Installation

Installing automotive electrical connectors types requires specific tools to ensure secure and efficient connections. Essential tools include:

Wire Strippers: Remove insulation from wires without damaging the conductor.

Crimping Tools: Securely attach connectors to wires, ensuring a strong mechanical bond.

Multimeter: Test electrical connections for continuity and voltage.

Heat Gun: Shrink heat-shrink tubing for added insulation and protection.

Screwdrivers and Pliers: Assist in manipulating wires and connectors during installation.

Safety Precautions

Safety remains paramount when working with automotive electrical connectors types. Follow these precautions to prevent accidents and ensure a successful installation:

Disconnect the Battery: Always disconnect the vehicle's battery before starting any electrical work to avoid short circuits or electric shocks.

Wear Protective Gear: Use gloves and safety glasses to protect against sharp wires and potential sparks.

Work in a Well-Ventilated Area: Ensure proper ventilation to avoid inhaling fumes from soldering or heat-shrinking processes.

Check for Power: Use a multimeter to verify that no power flows through the wires before handling them.

Step-by-Step Installation Guide

Connecting Blade Connectors

Prepare the Wires: Strip approximately 1/4 inch of insulation from the wire ends.

Select the Connector: Choose the appropriate blade connector size for the wire gauge.

Crimp the Connector: Insert the stripped wire into the connector and use a crimping tool to secure it.

Test the Connection: Use a multimeter to ensure continuity and proper connection.

Connecting Bullet Connectors

Strip the Wire Ends: Remove about 1/4 inch of insulation from each wire end.

Choose the Correct Connector: Select the right bullet connector size for the wire.

Crimp the Male and Female Parts: Insert the wire into the male and female parts of the connector and crimp them securely.

Join the Connectors: Push the male and female parts together until they click into place.

Verify the Connection: Check for a secure fit and test with a multimeter for continuity.

Connecting Pin Connectors

Prepare the Wires: Strip the insulation from the wire ends, exposing enough conductor for insertion.

Select the Pin Connector: Choose the appropriate pin connector for the application.

Insert the Wire: Place the stripped wire into the pin connector.

Crimp the Connection: Use a crimping tool to secure the wire within the connector.

Test the Connection: Ensure a stable connection by testing with a multimeter.

By following these installation techniques and best practices, individuals can achieve reliable and efficient connections with various automotive electrical connectors types. Proper preparation, tool selection, and adherence to safety precautions contribute to successful installations, enhancing the performance and durability of automotive systems.

Common Issues and Troubleshooting

Identifying Common Problems

Poor Connectivity

Automotive wiring connectors often face connectivity issues. Poor connectivity can result from loose connections or improper installation. When connectors do not fit tightly, they may cause intermittent electrical signals. This can lead to malfunctioning vehicle systems. Automotive experts emphasize the importance of ensuring connectors are securely attached to prevent such problems.

Corrosion and Wear

Corrosion and wear pose significant threats to automotive connectors. Exposure to moisture and harsh environmental conditions accelerates corrosion. This degrades the metal contacts, leading to poor electrical conductivity. Over time, wear and tear can also weaken the connector's structure. Manufacturers highlight the need for connectors with high IP ratings to withstand these harsh environments.

Solutions and Maintenance Tips

Cleaning and Maintenance

Regular cleaning and maintenance extend the life of automotive connectors. To clean connectors, use a contact cleaner to remove dirt and corrosion. This ensures optimal electrical conductivity. Automotive experts recommend inspecting connectors periodically for signs of wear or damage. Proper maintenance prevents connectivity issues and prolongs the connector's lifespan.

Replacement Guidelines

When connectors show signs of severe wear or corrosion, replacement becomes necessary. Choose connectors that match the original specifications for compatibility. Manufacturers advise considering current ratings and operating voltages when selecting replacements. Proper termination types also impact the assembly process. Following these guidelines ensures reliable performance and enhances the vehicle's electrical system integrity.

Choosing the right connector type is crucial for ensuring smooth communication between electronic components in vehicles. Automotive enthusiasts and professionals must understand the diverse types of connectors available. This knowledge enables them to maintain and repair vehicles effectively. Applying best practices in installation and maintenance enhances the reliability of these connections. Regular inspections and proper cleaning prevent common issues like poor connectivity and corrosion. By understanding and troubleshooting these problems, individuals can extend the lifespan of their vehicle's electrical systems, ensuring optimal performance and safety.

See Also

Uncovering Advantages of Fakra Auto Connectors

Essential HSD Connectors in Auto Sector

Significance of Fakra Auto Connectors in Contemporary Cars