Exploring Automotive Wiring Connector Types for Modern Vehicles

Automotive electrical connectors types are crucial in today's vehicles, facilitating seamless communication between various components. As vehicles become more advanced, the demand for superior connectors increases. The market for automotive electrical connectors is projected to expand from USD 11.1 billion in 2024 to USD 20.6 billion by 2032, underscoring their significance. Over the years, these connectors have evolved significantly, transitioning from simple designs to those capable of managing complex systems. Modern vehicles employ a variety of automotive electrical connectors types to meet the demands of new technologies. This evolution highlights the industry's commitment to safety and efficiency.

Understanding Automotive Electrical Connectors Types

Definition and Purpose

What are automotive wiring connectors?

Automotive wiring connectors are key parts in car electrical systems. They help connect different circuits, allowing car parts to talk to each other. These connectors come in many shapes and sizes for different car needs. They are used from big industrial tasks to small car lights, making sure cars work well.

Why are they essential in modern vehicles?

In today's cars, these connectors are very important. They let electronic parts work together for a smooth ride. By organizing wires neatly, they stop wires from getting messy inside the car. Also, they make designs easier to change, keep things safe, help find problems, and make fixing easier. As cars get more advanced, these connectors become even more important.

Basic Components

Knowing the basic parts of these connectors helps understand their use and importance.

Connector housing

The connector housing is like a shell that covers the inside parts of the connector. It keeps out water, dust, and shakes from outside. This shell makes sure the connector lasts long and stays strong.

Terminals and pins

Terminals and pins carry electricity through the connector. They link wires to the connector so signals move well. How they are made affects how good the connector works.

Seals and gaskets

Seals and gaskets stop dirt from getting into the connector. They fit tightly to keep moisture and dust out of the inside parts. By doing this, seals and gaskets help keep connections reliable.

Types of Car Electrical Connectors

Car electrical connectors are very important in new cars. They help parts talk and share power well. Knowing these helps pick the right one for each job.

Grouping by Job

Different car connectors do different jobs based on what they do. This grouping helps find the right connector for each work. different car connectors

Power Connectors

Power connectors move electricity between car parts. They make sure things like engines, lights, and radios get power to work. These need to handle lots of electricity and stay strong to stop losing power.

Signal Connectors

Signal connectors send small signals between electronic parts. They are key for things like sensors and control boxes. By sending signals right, they keep the car working well and safe. Signal connectors send small signals

Data Connectors

Data connectors are needed for fast data sharing in new cars. They help with tech like radios, maps, and car info systems. These must handle lots of data and keep connections safe for smooth talking.

Grouping by Shape

The shape of car connectors affects how they are used and work. Different shapes meet different needs in a car's electric system.

Blade Connectors

Blade connectors have flat blades that fit into slots. They often connect wires to things like fuses and relays. Their easy design makes them simple to put in or take out when needed often.

Pin Connectors

Pin connectors have round pins that go into matching holes. They give strong links for things like sensors and controls. The shape stops signal loss, making them good for important uses.

Coaxial Connectors

Coaxial connectors are made for high-speed signal moving. They're used in antennas and talk systems. The design cuts down on noise and keeps signals clear.

Rules and Guidelines

Knowing the rules for automotive electrical connectors is key. It keeps cars safe and working well. These rules help makers build connectors that fit needs and work great in different situations.

Important Rules

Rules are super important for making car connectors. They make sure connectors are safe, strong, and fit with car parts.

ISO rules

The International Organization for Standardization (ISO) makes global rules for car connectors. These rules tell how to make, test, and put in connectors. Following ISO rules means products meet world safety standards. This helps keep quality the same everywhere.

SAE rules

The Society of Automotive Engineers (SAE) also sets rules for car connectors. SAE looks at connector design, materials, and how they work in tough spots. These help makers build strong connectors for fast data sharing and tough conditions.

Maker's Own Rules

Besides big rules, makers have their own guidelines too. These match their products' special needs with car systems.

OEM needs

Original Equipment Manufacturers (OEMs) have special needs for their car connectors. They make sure these fit well with the car's electric system and meet quality checks. OEMs detail connector design, materials, and how they should perform.

Aftermarket thoughts

Aftermarket makers are big in the connector market too. They must fit existing systems and follow main rules to be safe and strong. Aftermarket parts often cost less than OEM ones, so they're popular for fixes or upgrades.

By knowing the guidelines for automotive electrical connectors, makers can create good products for today's cars. These ensure safety, strength, and fit with many systems, boosting vehicle life.

Installation and Care

How to Install

Installing car wiring connectors right makes them last long. Two ways are crimping and soldering.

Crimping the Right Way

Crimping means squeezing a connector onto a wire tightly. It's easy and works well. Use the right tools for the job. Pick the correct size tool for the wire and connector. Press evenly to make it strong. A good crimp stays firm even with shakes or bad weather.

Soldering vs. Crimping

Soldering melts metal to join wires and connectors. It makes a lasting bond but needs skill. Use it when you need a very strong link. Crimping is quicker for things you unplug often. Both have good points; pick what fits best.

Keeping Them Working

Checking wiring connectors often keeps them working well.

Look Often

Check connectors regularly to spot problems early. Look for wear, rust, or breaks. Loose parts can cause issues, so tighten them up. Regular checks help connectors last longer and keep cars running smoothly.

Clean and Protect

Keep connectors clean from dirt and water. These can mess up how they work. Use cleaners to wipe away grime. Add coatings to shield from tough conditions too. Clean, protected connectors help cars run safely.

In short, installing and caring for car wiring connectors is key for their life span and workability. By crimping properly, choosing between soldering or crimping as needed, checking often, and cleaning them, technicians ensure they work well in modern cars.

Picking the right car wiring connectors is very important. They help cars work well and stay safe. These tiny parts send electrical signals between systems. This lets electronic parts talk to each other easily. Without good connectors, cars would have big problems.

In the future, car wiring connectors will get better. They will become more efficient and reliable. Makers will keep creating new designs for modern cars' needs. As technology grows, designers and sellers must work together more closely. This teamwork is key to meeting new industry demands.

See Also

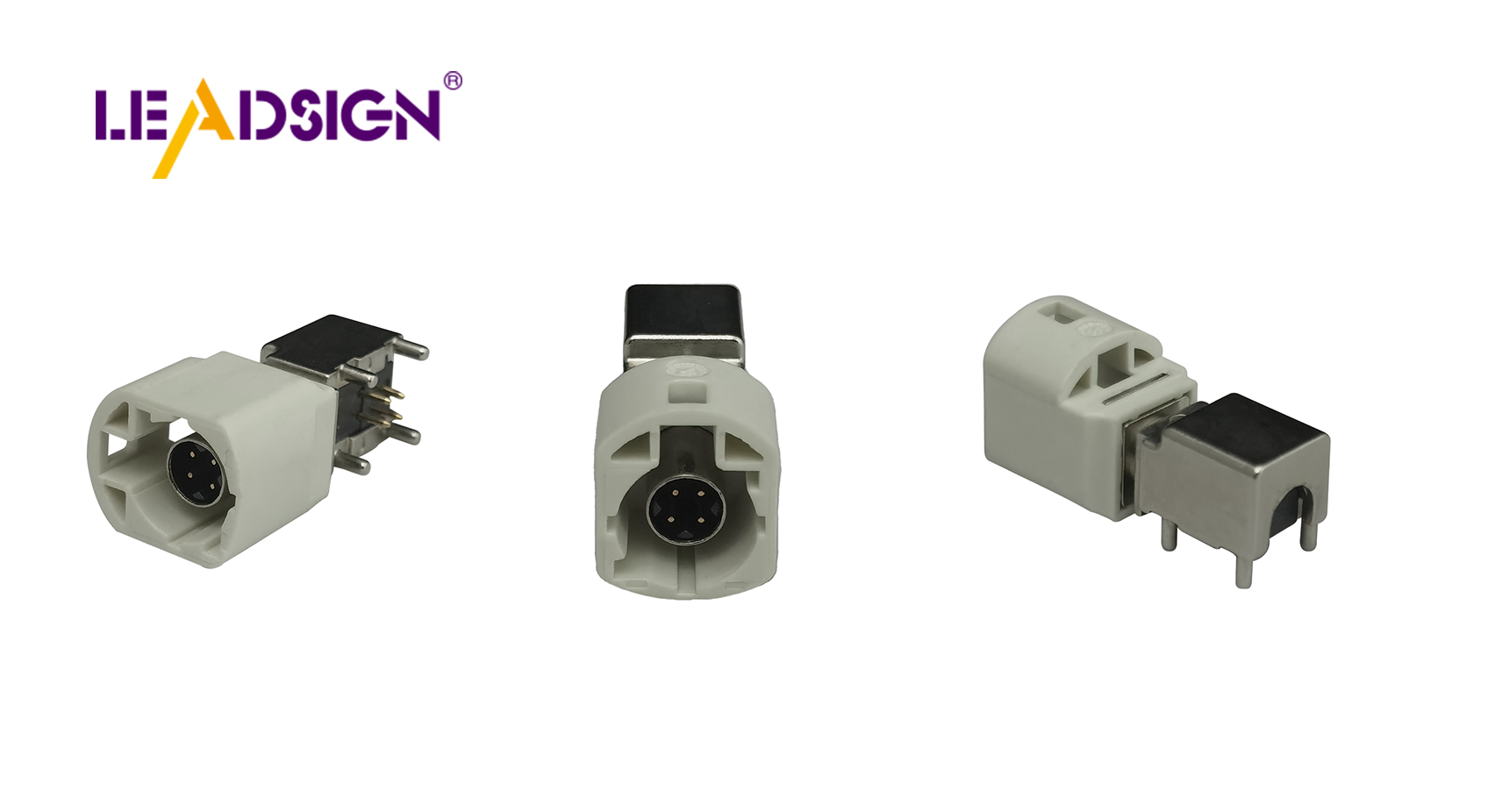

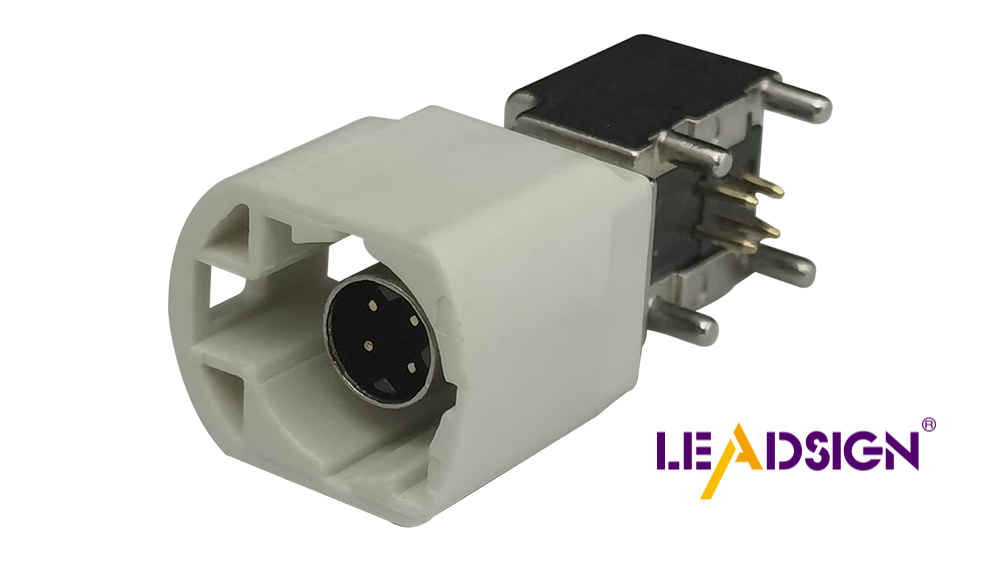

The Significance of Fakra Auto Connectors in Contemporary Cars

Fundamentals of HSD Connectors in Automotive Sector

Uncovering the Advantages of Fakra Auto Connectors