Exploring Automotive Wiring Connector Types for Modern Vehicles

Automotive electrical connectors come in various types and are crucial components in today's cars. They facilitate communication between different electronic parts within the vehicle. As automotive technology advances, the demand for more advanced connectors is increasing rapidly. The market for automotive electrical connectors is projected to reach a value of USD 20.6 billion by 2032, highlighting their significance in car electrification and safety systems. The evolution of connector types over time has led to significant improvements, meeting the intricate requirements of modern vehicles. These connectors are now more robust, secure, and efficient, showcasing the industry's commitment to innovation in automotive electrical connectors types.

Understanding Automotive Electrical Connectors Types

Basic Ideas

What They Are and Why They Matter

Car electrical connectors link different electronic parts in cars. They make sure electricity flows smoothly, so everything works well. These connectors come in many shapes and sizes for different needs. By giving a strong connection, they keep the car running safely.

Why They're Important in Cars

Connectors do more than just connect parts. They help the whole car work right. Connectors let systems like the engine and radio talk to each other. They are also key for safety things like airbags and brakes. As tech gets better, we need smarter connectors, showing their big role today.

How They're Grouped

ISO Rules

The International Organization for Standardization (ISO) makes rules for car connectors worldwide. These rules make sure connectors are good quality and safe. ISO helps makers create connectors that fit with all car systems, making them reliable everywhere.

Other Ways to Sort Them

Besides ISO rules, there are other ways to sort car connectors. These look at shape, size, or use of the connector. For example, some can handle water or heat better than others. This sorting helps pick the best connector for each job, making sure it lasts long.

Types of Car Electrical Connectors

Car electrical connectors are key for cars to work well. They connect parts, helping them talk and share power. Knowing different connectors helps choose the right one for each car job.

Common Car Electrical Connectors

Blade Connectors

Blade connectors are often in cars. They link wires and parts safely. A flat metal piece fits into a slot, making it secure. They're used in lights like headlights, needing a strong link to work right. Easy to put in and take out, they are popular in car connectors.

Pin Connectors

Pin connectors have pins that fit into sockets. They're used in control parts and sensors for clear data flow. These connectors keep signals steady, so power moves smoothly. They work well in engines and entertainment systems.

Special Connectors

Waterproof Connectors

Waterproof connectors handle tough weather well. They stop water from getting inside with seals and gaskets. Used in outside lights like fog lamps, they face rain often but stay reliable.

High-Temperature Connectors

High-temperature connectors work where it's hot, like near engines. Made from heat-proof stuff, they stay strong even when it's super warm. Used in exhausts or turbochargers, they don't break under heat stress.

How to Install Connectors

Putting in car connectors right helps cars work well and stay safe. Here’s a simple guide on what tools you need and steps to follow.

Tools You Need

To put in connectors, you need some special tools:

Wire Strippers: Take off wire covers without hurting them.

Crimping Tools: Attach connectors tightly to wires.

Multimeter: Checks if electricity flows right.

Heat Gun: Shrinks tubes for extra cover and safety.

These tools help make sure the connectors are put in safely, keeping the car's electric parts working well.

Steps to Follow

Get Ready: Gather all your tools and connectors. Make sure the car is off so no one gets shocked.

Strip Wires: Use wire strippers to take off about half an inch of cover from the wire ends. This shows the metal for a good link.

Crimp Wires: Put the bare wire into the connector. Use a crimping tool to hold it tight. A good crimp keeps it from coming loose.

Check Work: Use a multimeter to test your work. Make sure power flows right and there are no breaks.

Cover Up: Slide heat-shrink tubing over the connection. Use a heat gun to shrink it down, keeping water out.

Stay Safe

Avoid Mistakes

When putting in connectors, don’t do these things:

Don’t strip too much wire cover or wires might touch each other wrong.

Don’t crimp weakly or wires might come loose.

Don’t skip testing or problems might go unnoticed, making cars unsafe.

Keep Connections Strong

Strong connections keep cars running well. Do this:

Check crimps twice; they should be tight with wires fully inside.

Pick connectors that fit your car’s needs so everything matches up right.

Look at connections often for wear or damage; fix any bad ones fast.

"Right automotive connectors are key for how well and safe cars run," says a Connector Expert. Putting them in correctly keeps everything working smoothly in cars today.

By doing these steps, technicians can keep car electrical systems strong and safe, helping cars perform better and stay secure.

Common Problems and Fixes

Spotting Issues

Signs of Bad Connectors

Car connectors are important for systems to work well. But bad ones cause problems. Look for these signs:

On-and-Off Electrical Problems: Things might stop and start, showing a loose or rusty link.

Warning Lights: Dashboard lights may turn on because of weak connections.

Not Working Parts: Stuff like radios or lights might not work, hinting at a broken link.

Getting Too Hot: Heat near connectors can mean bad contact.

Finding these signs early stops more damage and keeps cars reliable.

How to Find Problems

Finding connector problems needs careful steps. Technicians use these ways:

Look Closely: Check connectors for wear, rust, or harm.

Test Flow: Use a multimeter to see if power goes through the connector.

Move Test: Wiggle the connector gently to see if it acts up, showing it's loose.

Check Voltage Drop: Measure voltage across the connector to find resistance issues.

These methods help find the problem so it can be fixed right.

Fixes and Repairs

Fixing Broken Connectors

Once bad connectors are found, they can be fixed by:

Cleaning Contacts: Use cleaner to remove rust and make connections good again.

Fitting Right: Make sure connectors fit tight to stop loose links.

Soldering Wires: Attach wires firmly if they came off the connector.

Changing Pins: Replace broken pins for strong connections.

Good repair makes car systems last longer and work better.

Replacing Connectors

Sometimes fixing isn't enough; replacing is needed. When changing connectors, think about:

OEM Match: Use Original Equipment Manufacturer (OEM) parts for best fit and work.

Quality Check: Pick connectors that meet safety rules and work well.

Special Features: Choose ones with waterproof or heat-proof features for certain uses.

Picking the right new connectors helps cars run safely and meet modern safety needs.

As cars get more advanced, we need connectors that move data fast and connect wires strongly.

See Also

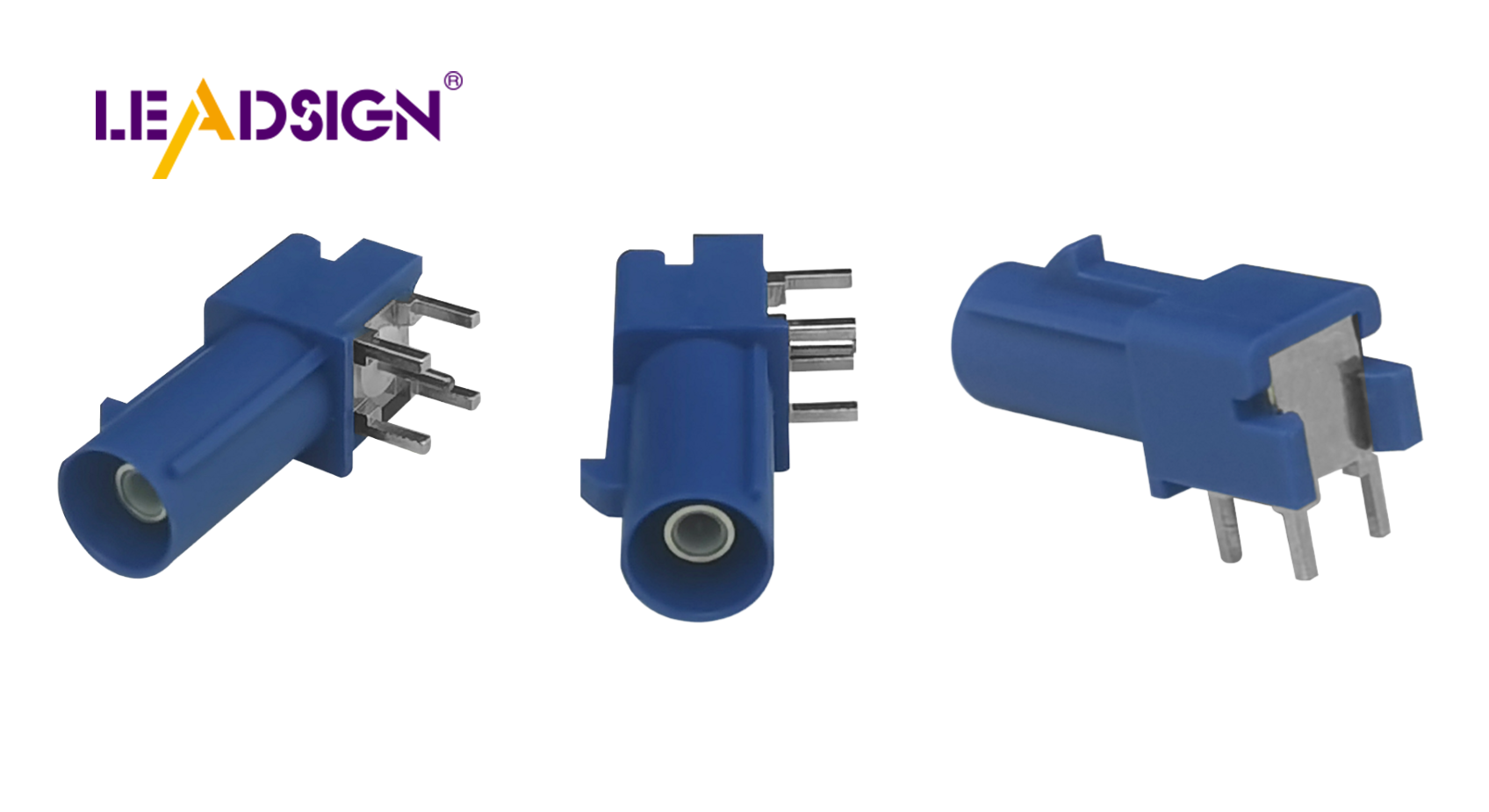

Significance of Fakra Auto Connectors in Contemporary Cars

Fundamentals of HSD Connectors in Auto Sector

Discovering Advantages of Fakra Auto Connectors