Exploring Different Automotive Wiring Connector Types

Car wire connector types are crucial in automotive systems. They facilitate communication between components within a vehicle. Various types of connectors exist, each serving a specific purpose. These connectors come in diverse shapes and sizes to cater to the requirements of modern cars. Understanding these car wire connector types is essential for enthusiasts and professionals in the automotive industry. This knowledge is vital for ensuring optimal functionality of your car's electronic systems.

Basics of Automotive Wiring Connectors

Definition and Purpose

What are wiring connectors?

Wiring connectors are important parts in a car's electric system. They connect different electronic parts and circuits like bridges. This helps everything work smoothly inside the car. Connectors come in many shapes, sizes, and designs to fit specific electrical needs.

Why are they essential in automotive systems?

In cars, wiring connectors are very important. They help electric signals move easily between parts. Without them, your car's electronics might not work well. They keep connections strong, reducing problems or breakdowns. Knowing their role helps you fix and care for your car’s electric system better.

General Characteristics

Common materials used

Car wiring connectors often use copper, brass, or bronze. These materials conduct electricity well and last long. Copper is common because it conducts electricity great and doesn’t rust easily. Brass and bronze also work well for many car uses due to similar benefits.

Standard features and specifications

Connectors have standard features that make them work better. Many have locks to keep connections secure so they don’t disconnect by accident. Some have waterproof seals to protect from water and dirt. These features ensure connectors work well in different situations.

Historical Evolution of Wiring Connectors

Early Developments

First designs and uses

Long ago, car connectors were very important. They were simple and basic. These connectors helped connect lights and engines. Early ones were big and made of rubber and metal. These materials kept electricity flowing safely in old cars.

Changes in materials and technology

As time went on, connector materials got better. Makers used stronger metals like copper and brass. This made connectors work better and last longer. Now, they are smaller due to new technology. This change let cars have more complex systems for better safety.

Modern Innovations

New connector technology

Today’s connectors are advanced. They have waterproof seals and locks to stay connected well. These features stop them from coming apart or getting wet. Also, they help send data fast for things like GPS.

Effects of digitalization and automation

Digital tools changed connectors a lot. Now, they support smart car systems that talk to each other easily. This helps with things like self-driving cars and safety features. Knowing about these modern connectors is key for car experts today.

Types of Car Wire Connectors

Knowing different car wire connectors is important for fixing cars. Each type has its own job and benefits.

Blade Connectors

What they are and how to use them

Blade connectors look like flat blades. You use them to join wires to parts like switches. They are easy to plug in and take out, perfect when you need to disconnect often.

Good points and downsides

Blade connectors are simple and easy. They hold a good connection for medium power. But, they might not stay tight if things shake a lot. They also don’t keep water out like some other types.

Pin Connectors

What they are and how to use them

Pin connectors have pins that fit into holes. You see them where strong connections are needed, like in engines. They stay connected well without coming apart by accident.

Good points and downsides

Pin connectors give a strong hold. They don’t loosen as easily as blade ones do. But, they can be hard to put in or take out, especially if space is tight. They might cost more too because they're complex.

Other Connector Types

Pigtail Connectors

Pigtail connectors join one wire to another or a part. They're flexible and useful in small spaces, stopping wire harm when setting up.

Terminal Blocks

Terminal blocks let many wires connect at one spot. You can easily change wires, which helps with repairs. They come in different sizes for various needs.

Bullet Connectors

Bullet connectors are round for quick joins. They're used in car lights but don't protect well from weather like others do.

Scotch Locks

Scotch locks let you join wires fast without cutting them open first. Just push the wire inside and close it up for a link. They're handy but might not be super strong or last long if things move around a lot.

Knowing these connector types helps pick the right one for your car's needs.

Practical Uses and Fixing Problems

How to Install

Best ways to install

When putting in car wire connectors, follow some good steps. First, use the right tools. Crimping tools help make strong connections if used right. Strip the wire to the correct length before putting it in the connector. This makes sure it fits well and stays tight.

Also, check that the connector type and size match the wire thickness. This stops problems from happening later. Always test after installing to see if it works. A simple test can show if everything is connected properly.

Mistakes to avoid

Avoiding mistakes during installation saves time and trouble later. One mistake is using a wrong connector type for where it's needed. For example, using a non-waterproof one where it's wet can cause rust.

Another mistake is not crimping well enough. A weak crimp can make wires come loose and fail electrically. Press hard when crimping so wires stay put. Lastly, don't forget to secure connectors tightly because they might shake loose in places like engine areas.

Fixing Common Problems

Finding bad connectors

Finding bad connectors keeps your car's electric system working well. Look at them closely for cracks or rust as these show problems.

You can also use a tool called a multimeter to check connections. If it shows no connection, there might be an issue with the connector. Watch for strange things happening in your car’s systems; this might mean a connector problem too.

Fixes and how to stop issues

If you find a bad connector, change it quickly to avoid more trouble. Use ones that fit your car's needs for best results. To stop future issues, check and clean them often.

Keep them free of dirt and water by using special grease that stops rust and helps them work better. Make sure all are fastened tight so they don’t move too much or shake apart over time.

Knowing about different automotive wiring connector types is important. They help your car work well and stay safe. These connectors let parts talk to each other, like the engine and radio. As you learn more, you'll see these small parts are very important for your car.

Automotive Connectors: "Wire connectors in cars are more important than they seem."

To learn more, check out car manuals, online groups, and videos. These can give you good advice on picking and using the right connectors for your car.

See Also

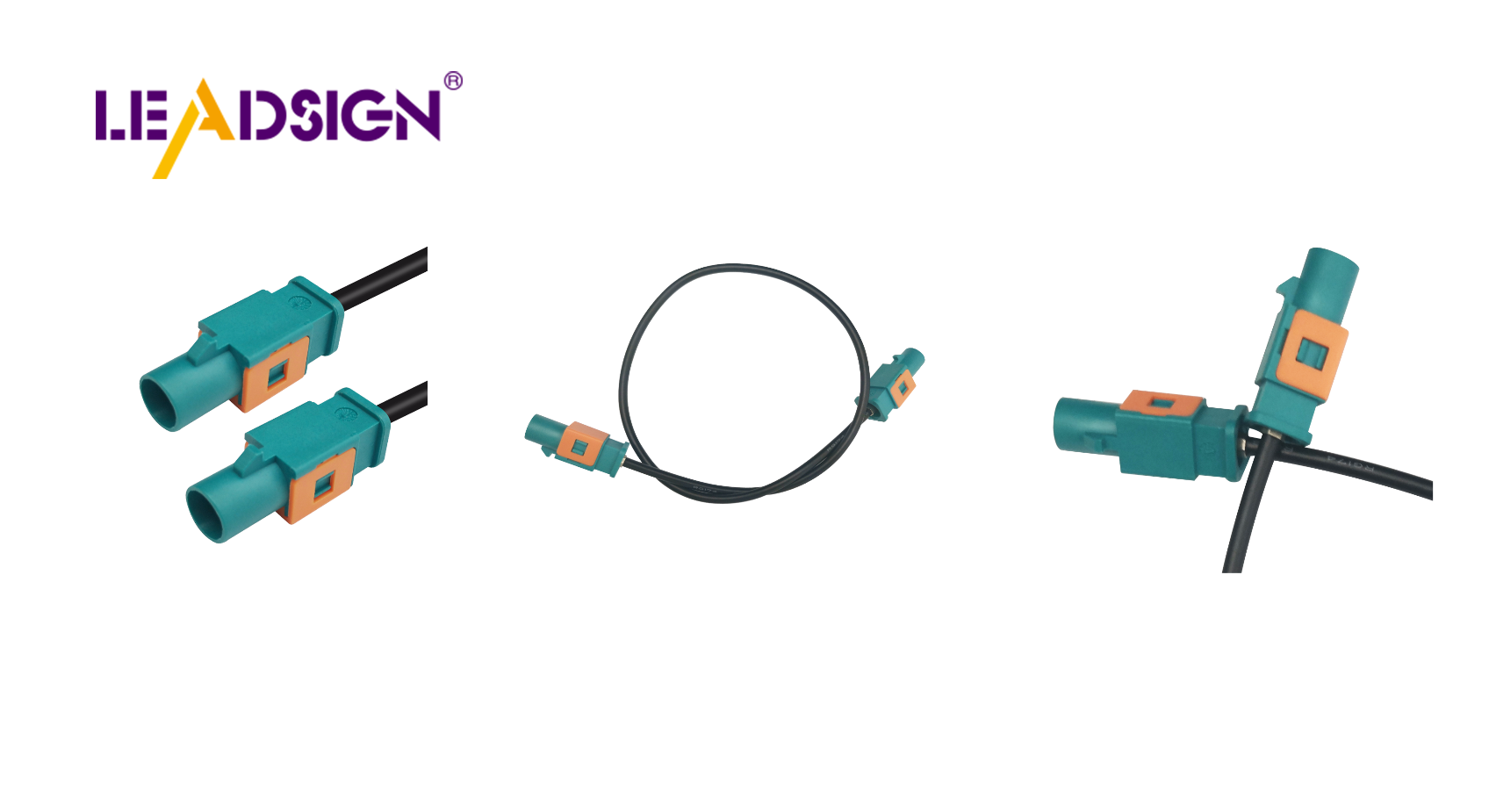

Discovering the Advantages of Fakra Auto Connectors

Fundamentals of HSD Connectors in Auto Sector

Significance of Fakra Auto Connectors in Today's Cars