Exploring Automotive Wire Connectors Types and Their Uses

Automotive wire connectors are crucial for car electrical systems, ensuring reliable connections between components. Various automotive wire connectors types are designed for specific tasks, playing a vital role in vehicle functionality. They facilitate the safe and efficient transmission of signals. Without these connectors, cars would not operate effectively. Understanding the different types helps in selecting the right connector, ensuring optimal performance and safety.

Understanding Automotive Wire Connectors

What are Automotive Wire Connectors?

Definition and purpose

Automotive wire connectors are key parts of car electrical systems. They help send electrical signals safely between car parts. These connectors have male (plug) and female (socket) pieces that connect wires. This lets electricity flow, powering things like the engine control unit and car radio. By making a strong link, these connectors keep cars working well and safe.

Importance in vehicle electrical systems

Wire connectors are very important in car electrical systems. They help different electronic parts talk to each other well. Without them, signals wouldn't go where they need to, causing problems. For example, they send signals to the engine control unit for good engine work. They also help infotainment systems run smoothly, making driving better.

Key Features of Wire Connectors

Material composition

The materials used in wire connectors affect how they work. Common ones are copper, brass, and bronze. These metals carry electricity well and don't rust easily, lasting long. The material choice depends on what the car needs, like being bendy or strong.

Durability and reliability factors

Durability and reliability are crucial for automotive wire connectors. They must handle tough conditions like heat changes and shaking. Things like crimp connections make them last longer. Weather Pack connectors seal out water and dirt for protection. Deutsch connectors are tough in hard places too. These features keep connections safe and efficient in cars.

Types of Automotive Wire Connectors

Knowing different automotive wire connectors is key for car systems to work well. Each type has a special job and gives certain benefits.

Crimp Connectors

Description and applications

Crimp connectors are popular in cars because they are easy to use and hold tight. They have a metal part that squeezes onto the wire, making it stay put. These connectors are great for high power jobs where strong links matter. People use crimp connectors when they need to join wires fast and well.

Advantages and disadvantages

Advantages:

Easy and quick to set up

Makes a strong link

Good for high power tasks

Disadvantages:

Needs special tools to squeeze

Bad squeezing can make weak links

Solder Connectors

Description and applications

Solder connectors join wires with melted metal, making a lasting link. This way makes sure electricity flows well, perfect for jobs needing steady links. Solder connectors are used when wires won't be taken apart often.

Advantages and disadvantages

Advantages:

Makes a lasting, good link

Best for long-lasting tasks

Disadvantages:

Needs heat and skill to melt metal right

Not good if wires need taking apart often

Quick Disconnects

Description and applications

Quick disconnects or spade terminals let you easily take apart or put together wires. They’re made for places where changes happen often. Quick disconnects are used in cars where parts might need fixing or changing a lot.

Advantages and disadvantages

Advantages:

Fast to take apart or put back

Helps with easy fixes or changes

Disadvantages:

Might not hold as tight as other types

Can get loose if used too much

By knowing these automotive wire connectors, people can pick the best one for their needs. Each type has its own good points and downsides, so choosing the right one is important.

Other Types of Automotive Wire Connectors

Pigtail Connectors: Description and Applications

Pigtail connectors are important for car electrical systems. They join wires to devices, helping signals move safely. These connectors have a short wire attached, making them easy to use with other wires. Pigtail connectors are used in cars for things like headlights and tail lights.

Advantages and Disadvantages

Advantages:

Makes connecting easier with a wire already attached.

Lowers chance of wrong wiring because it's simple.

Can connect different wire sizes easily.

Disadvantages:

Needs more space due to extra wire.

Might fail if not covered well.

Bullet Connectors: Description and Applications

Bullet connectors look like bullets and are crimp connectors used in cars. They make it easy to connect or disconnect wires. Bullet connectors work well when you need to unplug and plug wires often, like in trailers or motorcycles.

Advantages and Disadvantages

Advantages:

Simple to plug in or out, good for temporary links.

Stays connected firmly so it doesn't come apart by accident.

Works with many wire sizes.

Disadvantages:

Can get loose if shaken a lot.

Needs careful squeezing for a strong link.

Sealed Connectors: Description and Applications

Sealed connectors protect car electrical links from water, dust, and dirt. They have seals like rubber rings that keep bad stuff out. Sealed connectors are used where it's wet or dirty, like near engines or outside lights.

Advantages and Disadvantages

Advantages:

Keeps connections safe from weather problems.

Stops rusting and electric issues.

Good for wet or dusty places.

Disadvantages:

Cost more than open ones.

Might need special tools to put on or fix.

Knowing these automotive wire connector types helps pick the right one. Each type has good points and downsides, so choosing wisely is key for safety and performance.

Installation Techniques

Installing automotive wire connectors right is key for safe car connections. Here’s a simple guide on tools and steps to do it well, plus mistakes to avoid.

Proper Installation Methods

Tools Needed

To install wire connectors, you need certain tools:

Wire Strippers: Take off wire cover without harm.

Crimping Tool: For crimp connectors, makes strong links.

Soldering Iron: For solder connectors, gives lasting joins.

Heat Gun: For heat shrink, seals waterproof.

Multimeter: Checks if connection works right.

Step-by-Step Guide

Preparation: Get all tools ready. Turn off car power for safety.

Wire Stripping: Use strippers to remove 1/4 inch of cover. This shows metal for connecting.

Connector Choice: Pick the right connector type. Crimp for quick jobs, solder for permanent ones.

Crimping Process:

Put wire in crimp connector.

Squeeze with tool to hold tight.

Soldering Process:

Twist wire ends together.

Heat iron and add solder to join firmly.

Heat Shrink Use: Slide tube over join. Heat it so it shrinks and protects.

Testing: Use multimeter to check if connection is good and has right voltage.

Common Mistakes to Avoid

Bad Crimping

Bad crimping makes weak links. To fix this:

Fully insert wire before squeezing.

Use the right tool for each connector.

Press hard enough for a strong hold.

Overheating When Soldering

Too much heat can hurt wires. To stop this:

Use iron with temperature control.

Heat only until solder flows nicely.

Don’t heat too long on wires or connectors.

By using these tips and avoiding mistakes, you keep your car's electrical system working safely and well. Knowing about different types of connectors and how to install them is important for good connections.

Q&A: Common Issues and Maintenance Tips

Frequently Asked Questions

Troubleshooting Common Problems

Automotive wire connectors are key for car electrical systems. But, problems can happen. Here are some common issues and how to fix them:

Loose Connections: Loose connections cause power problems. To fix, make sure connectors fit tightly and lock in place. Use a multimeter to check if electricity flows.

Corrosion: Rust stops electricity from flowing well. Check connectors often for rust or corrosion signs. Clean with contact cleaner and use grease to stop future rust.

Overheating: Heat can harm connectors. Look for melting or color changes. Make sure connectors handle the right power level and replace any damaged ones.

Wire Breakage: Broken wires stop things from working. Look for broken or frayed wires. Fix or change bad wires and support them to avoid future breaks.

Expert Testimony:

An expert says, "Wire connector types in cars are more important than you might think." They help send signals all over the car, powering parts like the engine control unit and radio."

Best Practices for Maintenance

Taking care of automotive wire connectors makes them last longer and work better:

Regular Inspections: Check all connectors often for wear, rust, or damage to catch problems early.

Proper Handling: Be gentle with connectors; don't pull on wires, use tools correctly.

Environmental Protection: Use sealed connectors where it's wet or dirty to keep them safe.

Maintenance Tips

Regular Inspection Routines

Checking automotive wire connectors keeps them working well:

Visual Check: Look at connectors for cracks or breaks; ensure they connect securely.

Functional Test: Use a multimeter to see if electricity flows right; find hidden issues this way.

Environmental Assessment: See if they're exposed to harsh conditions; protect with seals if needed.

Cleaning and Care Advice

Cleaning helps automotive wire connectors last longer:

Cleaning: Remove dirt with contact cleaner; don't use water that harms them.

Lubrication: Put grease on them to keep out moisture and stop rusting.

Storage: Keep spare ones dry and cool; protect from dust so they stay good.

By following these tips, car owners can keep their automotive wire connectors working well, helping their cars run safely.

Automotive wire connectors are key for car electrical systems. Knowing different types, like crimp and Deutsch connectors, helps pick the best one. The right choice boosts performance and safety.

Automotive Connectors Experts say, "Each type has special features and uses."

Using these tips can make car systems work better and last longer.

See Also

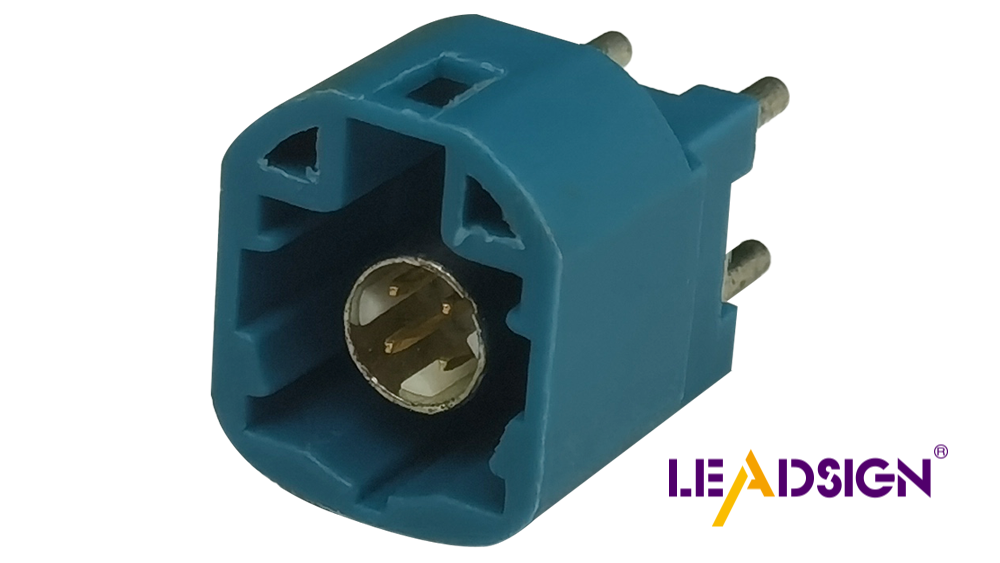

Discovering the Advantages of Fakra Car Connectors

Essential Information on HSD Connectors for Cars

The Benefits of HFM Connectors in Automotive Applications