Exploring Automotive Wire Connectors Types

Automotive wire connectors types play a crucial role in modern vehicles. They ensure that electrical connections function efficiently, which is essential for systems to operate smoothly. These connectors transmit signals between components, powering essential features like the engine and radio. As vehicles become more advanced with technology, the demand for faster connectors increases. Understanding the various types of automotive wire connectors is key to maintaining the reliability and performance of cars.

Basics of Automotive Wire Connectors

Definition and Purpose

What are wire connectors?

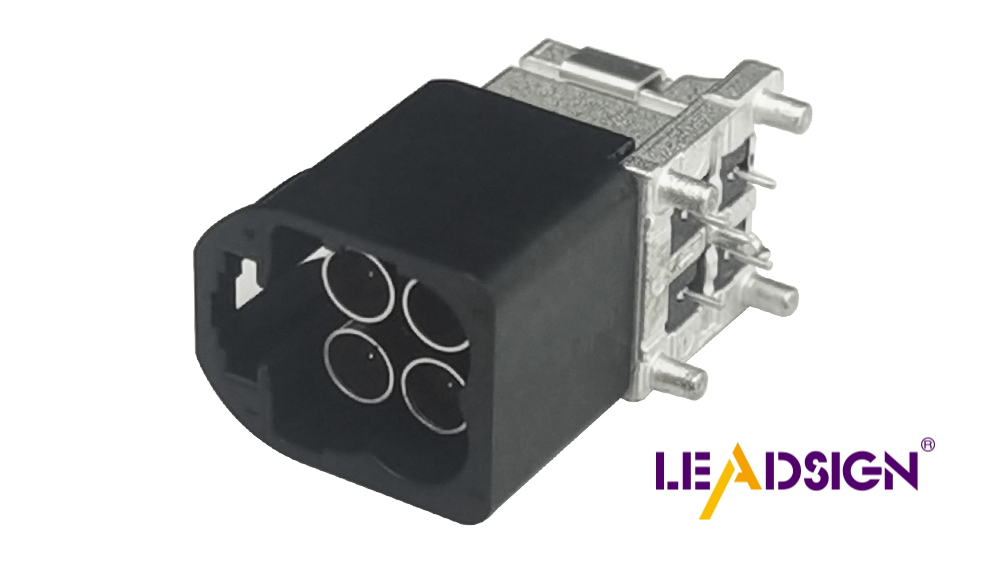

Wire connectors are important in cars. They help send electrical signals between different parts. These have male (plug) and female (socket) parts that fit together well. Their main job is to let car parts talk and work together. This helps systems like the engine and radio run smoothly.

Why are they essential in vehicles?

Wire connectors are crucial because they keep electrical connections strong. They make sure all electronic systems work together for a smooth drive. Without good connectors, cars would often break down, affecting performance and safety. As technology grows, faster connectors become more needed in modern cars.

General Characteristics

Materials used

Copper, brass, or bronze are common materials for wire connectors. These materials conduct electricity well and resist rusting, which keeps them reliable over time. The material choice affects how well the connector works and lasts.

Common features and specifications

Automotive wire connectors have key features:

High Conductivity: Sends electrical signals efficiently.

Corrosion Resistance: Protects against weather damage.

Variety of Types: Includes crimp connectors for secure bonds, and Weather Pack for outdoor use.

Durability: Products like Deutsch Connectors resist weather, good for tough jobs.

These traits make wire connectors crucial for car systems to work well under different conditions.

Types of Automotive Wire Connectors

Blade Connectors

Description and uses

Blade connectors are flat metal pieces. They fit into slots. These are used in cars for electrical parts. You see them in fuse boxes and relay panels. They help spread power well.

Advantages and disadvantages

Advantages:

Easy to plug and unplug.

Give a steady connection.

Good for high-power use.

Disadvantages:

Can get loose if not tight.

Rust if they get wet.

Ring and Spade Connectors

Description and uses

Ring and spade connectors attach to posts securely. Rings make a circle, spades look like forks. They're great for battery ends and grounding wires.

Advantages and disadvantages

Advantages:

Strong, secure hold.

Simple with screws or bolts.

Conduct electricity well.

Disadvantages:

Need tools to put on or take off.

Might loosen if not tight enough.

Butt Connectors

Description and uses

Butt connectors link two wire ends together. They're common in car fixes, making wire joins easy. They keep electricity flowing smoothly between wires.

Advantages and disadvantages

Advantages:

Easy to use.

Strong, covered connection.

Perfect for fixing broken wires.

Disadvantages:

Might need crimping tools to stay tight.

Not good where there's lots of shaking without extra help.

Different automotive wire connectors like blade, ring, spade, and butt types are key for cars working right. Each has its own pros and cons, so picking the right one is important.

Other Automotive Wire Connectors Types

Pigtail Connectors

Pigtail connectors are important in car wiring. They let one wire connect to many parts. This is great when you need several connections from one spot. Pigtail connectors make tricky wiring jobs easier. They help signals go where they should without stopping.

Terminal Blocks

Terminal blocks keep wires neat and safe in cars. They are like meeting points for wires, making it easy to join or separate them. This is handy when cars need fixing or changing often. Terminal blocks keep connections strong and lower the chance of problems.

"Terminal blocks make car wiring tidy, keeping connections safe and easy to reach."

Bullet Connectors

Bullet connectors are made for quick hookups. They have a male and female end that fit well together, making connecting simple. Bullet connectors are perfect when you need to change connections often. Unlike other types, bullet connectors work best where flexibility is key.

Comparative Data:

Wire-to-wire connectors: Help wires link smoothly in cars.

Bullet connectors: Crimp type used for frequent changes.

Each car wire connector type has its own job in helping cars run well. Knowing about these helps pick the right one for each task, boosting car system performance and trustworthiness.

Common Problems and Fixes

Connection Issues

Why Connections Fail

Connections can fail for many reasons. Loose connectors happen if not secured well. Car movement shakes them loose over time. Bad installation like wrong crimping or connector choice causes issues too. Water and dirt make connections worse.

How to Stop Failures

Check connectors often to stop failures. Make sure they are tight for a good link. Use the right connector for each job to avoid problems. Grease helps keep water away from connectors. Teach workers how to install them correctly to avoid mistakes.

Rust Problems

Why Rust Happens

Rust happens when water and salt get in connectors. They cause rust and damage inside. Bad seals or broken covers let water in faster. Wet weather and road salt make it worse.

How to Fix Rust

Use rust-proof materials for connectors to fight rust. Clean them often to remove dirt and water buildup. Coatings protect from outside harm. Seal well during setup to keep water out. Regular checks find rust early, keeping connections strong.

Knowing about car wire connectors is important for keeping cars working well. Connectors help make sure electricity flows right. There are different types like blade, ring, and butt connectors. Picking the right one stops problems like loose parts and rust. This can stop things from breaking. To learn more, look up how to care for connectors and new connector ideas. These tips help you choose the best connectors for cars, making them safer and work better.

See Also

Discovering Advantages of Fakra Car Connectors

Fundamentals of HSD Connectors in Auto Sector

Significance of Fakra Connectors in Auto Sector