Exploring Automotive Wire Connectors Types

In cars, automotive wire connectors types are very important. They help the car's electrical systems work well. These connectors make sure connections are strong and safe. This protects your car's warranty and makes it last longer. They are made from strong materials like nylon and rubber-like plastics. These materials can handle tough conditions. You can install them easily, and they keep water out. Knowing about different wire connectors helps your car run better for a long time.

Understanding Automotive Wire Connectors

Basic Ideas

What They Are and Do

Car wire connectors are key parts of your car's electrical system. They link wires, making sure the connection is strong and safe. This strength is needed for your car's gadgets to work right. You need these connectors to keep the electric flow steady, powering things like lights and music systems.

Why They're Important in Cars

You might ask why these connectors matter so much. They help keep your car's electrical system working well and safely. By making strong links, they fit with your car's gadgets perfectly. This fit is crucial for smooth driving. Plus, they last long even in tough places, shielding your car from harm.

Past Background

How Wire Connectors Changed

The story of wire connectors in cars is interesting. At first, simple ones joined wires together. But as cars got more complex, better connectors were needed. You can see how they've changed to meet new car needs today. Now they're made for fast data and tough conditions.

New Tech Changes

New tech has greatly changed car wire connectors' growth. Today's connectors have cool features like locks and strong grips on cables. These changes make sure your car's electric system stays strong and works well. Also, different codes stop wrong connections, boosting safety and performance.

Types of Car Wire Connectors

Knowing about car wire connectors helps you fix your car's electric parts. These connectors are grouped by how they look, work, and where they're used. Each type helps different car parts talk to each other and get power.

By Look

Flat Connectors

Flat connectors are very common in cars. They have a flat shape like a blade. You slide them into a matching slot for a good fit. This makes them great for quick and strong links in cars. Use them when you need to connect or disconnect wires often without losing the connection.

Round Connectors

Round connectors are easy to use for joining wires. They have two ends that fit together tightly. You might use round connectors in tight spaces because they are small and easy to put in place. They are good for connections that change often or don't last long.

By Job

Big Power Connectors

Big power connectors carry lots of electricity, powering big car parts like the starter motor. These make sure power moves well from the battery to other parts. Pick ones that can handle your car's power needs.

Data Connectors

Data connectors send signals between car parts like sensors and controls. They usually carry little power but keep connections steady so your car works safely and well.

By Use

Water-Proof Connectors

Water-proof connectors keep water out of electric links, stopping rust and problems. Use these where it's wet or dirty, like near the engine or under the car.

Heat-Proof Connectors

Heat-proof connectors can take high heat without breaking down, perfect near engines or exhausts. They stop heat damage so your car's electric parts stay working right.

By learning about these wire connector types, you pick the best ones for your car's needs, keeping it safe and running well.

How to Install Connectors

Tools You Need

To put in car wire connectors, you need some tools. Here’s what to get:

Crimping Tools

Crimping tools help attach connectors to wires. They make sure the fit is tight and strong. Pick a crimping tool that matches your connector type.

Soldering Gear

Soldering gear makes a strong link between wires and connectors. It’s needed for extra-strong connections. Have a soldering iron and solder wire ready.

Easy Steps Guide

Follow these steps to put on your wire connectors right:

Getting Wires Ready

Take Off Cover: Use a wire stripper to take off about half an inch of cover from the wire ends. This shows the metal for better linking.

Twist Wire Ends: Twist the bare wire ends together. This stops them from fraying and helps connect easier.

Look for Problems: Check wires for any damage or wear signs. Change bad wires to keep connections safe.

Putting on Connectors

Pick Right Connector: Choose a connector that fits the wire size and job. Like, use waterproof ones where it's wet.

Crimp Connector On: Put the connector on the wire and use crimping tools to fix it tight so it stays put.

Add Solder if Needed: If needed, add solder for more security. Heat up the solder iron and touch it to join until covered well.

Cover Connection: Use heat shrink tubing or tape over connection for extra protection from water and rust.

By doing these steps, you make sure your car's wire connectors are set right, helping your car work better and last longer.

Common Problems and Fixes

Finding Issues

Spotting Bad Connections

If your car's electric parts aren't working right, it might be bad wire connections. First, check for loose or rusty connectors. Look for worn-out or broken wires and connectors. Use a multimeter to test if the connection is complete. If it shows a break, you've found the problem.

Fixing Broken Connectors

After finding a broken connector, fix it to make things work again. Start by taking off the bad connector. Clean rust with a wire brush or cleaner. If it's too damaged, get a new one that fits the wire size and type. Use crimping tools to attach it tightly. Add solder for strength and cover with heat shrink tubing to keep out water and dirt.

Questions & Answers

Commonly Asked Questions

Why do wire connectors break?

They can break from rust, damage, or wrong fitting. Water and dirt cause rust which weakens them.

How often should I check my car's connectors?

Check every six months or if you see problems.

Can I use any connector on my car?

No, use ones that fit your car's system by design and job.

Expert Advice

Expert in Car Wiring Connectors: "Using OEM connectors from trusted makers gives strong electric links. Their high quality makes them great for many uses."

Tip 1: Always pick good-quality connectors from known brands.

Tip 2: Keep them clean and dry to stop rust.

Tip 3: Make sure they fit tight to avoid loose links causing failures.

By knowing these common problems and fixes, you can keep your car's electric system running well for safe driving.

Picking the right wire connectors is key for your car's electric system. Good OEM connectors make strong and safe links. They fit well with your car's original parts, making them last longer and saving money. By using what you've learned, you can boost your car's electric work.

Remember:

Choose connectors that suit your car.

Check and care for them often to keep them working well.

Buy good ones to stop future problems.

"Buying top-quality OEM automotive wire connectors is important for making sure electric connections are correct.

See Also

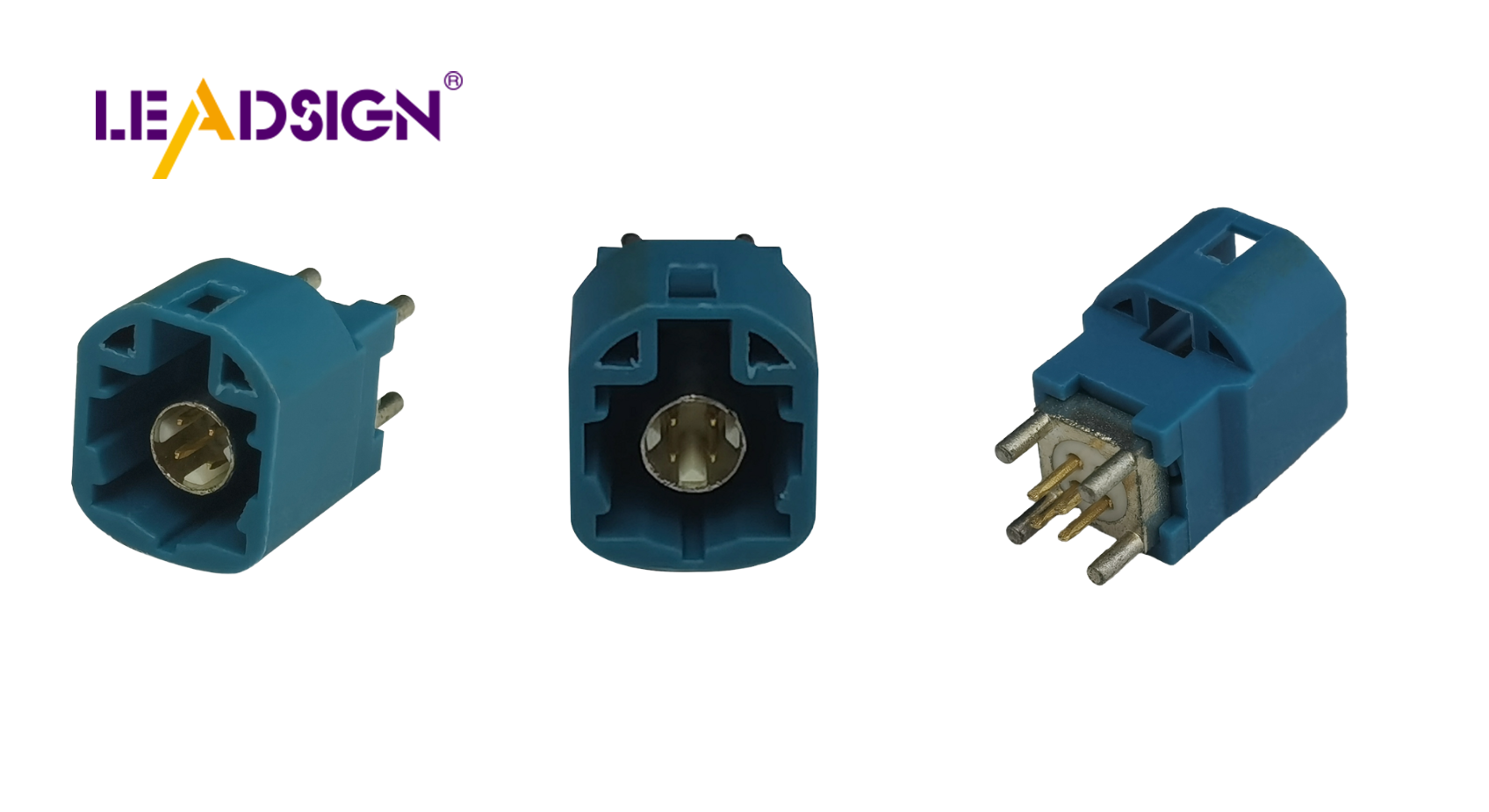

Discovering Advantages of Fakra Auto Connectors

Fundamentals of HSD Connectors for Auto Sector

Significance of Fakra Connectors in Auto Sector