Exploring Various Automotive Wire Connector Types

In cars, automotive wire connectors types are very important as they help car parts communicate effectively. Without good connectors, you might experience power or signal issues. There are various types, such as pigtail, terminal blocks, and bullet connectors, each serving a specific purpose to ensure your car functions smoothly. The HSD PCB Connector is excellent for fast data transfer, making it a crucial component in maintaining the reliability of your car's electrical system. Understanding these connectors helps keep your vehicle's electronics dependable.

Basics of Automotive Wire Connectors

Definition and Purpose

What are wire connectors?

Wire connectors are key parts in cars. They help electronic parts talk to each other. They come in different shapes and sizes. Each type has a job to do, making sure your car's electrical system works well. Some common ones are pigtail, terminal blocks, bullet connectors, and scotch locks. These keep wires connected firmly, which is important for your car’s performance.

Why are they essential in automotive systems?

In cars, wire connectors are very important. They make sure power and signals move smoothly between parts. Without them, you might have power loss or signal problems. This can cause parts to break or the whole system to fail. Using the right connectors stops these issues and keeps your car working well. Makers design them for specific needs so they fit and work perfectly in cars.

General Characteristics

Material composition

The materials of wire connectors affect how they work. Most use plastic or metal or both together. Plastic gives protection from weather, while metal makes strong connections. Some have extra coatings to last longer and stop rusting. Knowing what they're made of helps you pick the best ones for your car.

Durability and resistance features

Durability is key for wire connectors in cars. You need ones that handle tough conditions like heat, wetness, and shaking. Many have sealed designs or heat-proof materials for long life. These features protect connections from harm over time. Choosing strong connectors boosts your car's electrical system reliability.

Types of Automotive Wire Connectors

Knowing the different automotive wire connectors helps pick the right one for your car. Each type has a special job, making sure your car's electrical system works well.

Crimp Connectors

Crimp connectors are liked in cars because they are easy to use and reliable.

Types of crimp connectors

Butt Connectors: These connect two wires end-to-end securely.

Ring Terminals: Attach wires to a stud or screw firmly.

Spade Terminals: Easy to connect and disconnect, great for frequent changes.

Advantages and disadvantages

Advantages:

Easy to Install: You can put them on quickly with few tools.

Strong Hold: They keep connections tight, stopping disconnections.

Disadvantages:

Permanent Fit: Hard to remove once crimped without cutting.

Tool Need: Special tools needed for good crimping.

Solder Connectors

Solder connectors make a lasting connection by joining wires together.

Types of solder connectors

Heat Shrink Solder Sleeves: Solder and insulate in one step, sealing out water.

Solder Lugs: Attach wires to terminals securely.

Pros and cons

Pros:

Long-lasting: Good against shaking and weather changes.

Great Conductivity: Excellent at carrying electricity with low resistance.

Cons:

Takes Time and Skill: More time-consuming than crimping.

Not Reversible: Once done, hard to change connections.

Push-On Connectors

Push-on connectors, also called quick disconnects, make wiring easy in cars.

Types of push-on connectors

Male and Female Disconnects: Fit together easily but separate quickly too.

Tab and Receptacle Connectors: Simple and reliable for many car uses.

Benefits and limitations

Benefits

Fast Setup: Quick connect/disconnect without needing tools.

Flexible Use: Works well in many setups offering flexibility.

Limitations

Loose Connections Possible:** May loosen if not secured well over time.

Limited Current Capacity:** Not suited for high power due to overheating risk.

By knowing these types of wire connectors, you can choose wisely for your car's electrical needs. Each offers unique features helping you find the best fit for your needs.

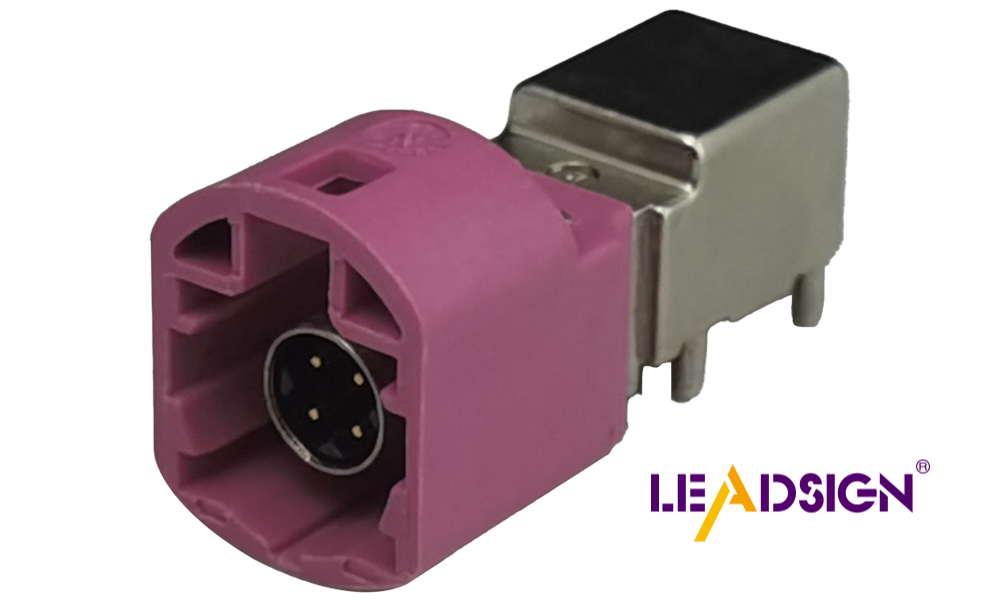

HSD PCB Connector

Uses in car systems

The HSD PCB Connector is key in new car systems. It's used where fast data is needed, like in entertainment and driver-help systems. These connectors help your car's electronics talk well, aiding things like maps, music, and safety alerts.

Besides cars, the HSD PCB Connector is also used in telecoms, like radio stations. It works with digital networks and USBs from USB 1.0 to USB 3.0. This makes it important for smooth data flow across many platforms.

Benefits of using HSD PCB connectors

Using HSD PCB Connectors in cars has many perks. They allow fast data movement, which is vital for quick data tasks. This keeps your car's systems running without delays.

They also stop interference by cutting signal loss and distortion. This keeps data clear for things like maps and crash-avoidance tech.

Plus, these connectors are small but strong. They fit into tight spots in your car's electronics, perfect for modern cars with little space. Their toughness means they handle tough conditions like heat changes and shaking.

How to Install Connectors

Tools You Need

Important tools for the job

To put in automotive wire connectors, you need certain tools. These help make sure connections are safe and work well:

Wire Strippers: Take off insulation without harming the wire.

Crimping Tool: Holds crimp connectors tightly.

Soldering Iron: Needed for solder connectors, makes a strong link.

Heat Gun: Use on heat shrink connectors to cover and protect.

Multimeter: Test connections for good flow and correct voltage.

Safety tips

Being safe is key when working with car wires. Follow these safety tips:

Unplug the Battery: Stops shocks or short circuits from happening.

Wear Safety Gear: Put on gloves and goggles to stay safe.

Work in Bright Light: See clearly to avoid errors.

Stay Dry: Work in dry places to stop electrical dangers.

Steps to Install

Getting wires ready

Cut Wire Lengths: Use cutters to get the right length of wire.

Strip Insulation Off: Take off about half an inch using strippers.

Twist Wires Together: Twist bare strands so they stay together.

Joining wires

Pick a Connector Type: Choose the right connector for your task.

Connect Wires Together:

For crimp types, put wire in and use tool to secure it tight.

For solder types, add solder with iron for a firm bond.

Cover Connection Well: Heat gun seals heat shrink connectors against water.

Check Connection Works: Multimeter checks if connection is solid and works.

By doing these steps, you make sure your car's wiring is safe and reliable. Good installation helps your car's parts last longer and work better.

Fixing Connection Problems

Finding bad connections

Your car might have electrical issues from bad wire links. To find these, check for wires that are loose or not connected. Look for rust or damage on the connectors. Use a multimeter to see if electricity flows through the wires. If it doesn't, the connection is bad. Watch out for strange things in your car's electronics, like lights flickering or power cutting out, as these show connection problems.

Fixing common problems

After finding a bad connection, you can fix it. For loose wires, make sure they are tightly connected to the connectors. Tighten screws or fasteners holding them in place. If there's rust, clean it with a wire brush or sandpaper. Put on a protective layer to stop more rust later. Swap broken connectors with new ones for better links. Always recheck with a multimeter to ensure it's fixed.

Keeping Things Working Well

Regular checks

Regular checks keep your car's electrical system working well. Check your wire connectors every few months as a habit. Look for worn-out parts like frayed wires or cracked covers. Check connectors for rust or damage signs too. Make sure all connections are tight and secure so you can catch small issues early before they become big problems.

Tips to make them last longer

To make your wire connectors last longer, follow some tips: Use good-quality ones made for cars because they're tougher and handle harsh conditions better. Keep them clean and dry by using dielectric grease to stop rusting. Don't overload your electrical system since too much heat can harm the connectors. By doing this, you'll keep your car's electrical system reliable for years.

Picking the right car wire connector is very important. Each kind has a special job to help your car's electrical parts work well. Choosing the right one makes things more reliable and efficient, stopping problems like rust. Regular check-ups and knowing what connectors are made of help them last longer. Keep your car's electronics working by learning more and making smart choices.

See Also

Discovering the Advantages of Fakra Car Connectors

Fundamentals of HSD Connectors in Auto Sector

Significance of Fakra Car Connectors in Today's Cars