Understanding the Evolution of Car Wiring Wire in Modern Vehicles

Car wiring wire has changed the car industry a lot. Old cars used simple electrical systems. Today, cars have complex wiring networks. Wiring now powers safety features, entertainment, and electric engines. Connected cars and electric vehicles need better wiring solutions. Makers use lighter materials and high-voltage systems for this. These changes show how wiring helps improve car technology and keeps cars working well.

Key Takeaways

Car wiring has evolved from simple systems in early vehicles to complex networks that support advanced features like safety systems and electric engines.

The introduction of multi-wire harnesses and standard connectors has made car wiring easier to install and repair, enhancing reliability and safety.

Modern vehicles utilize the CAN bus system to reduce the number of wires needed, improving data sharing and overall efficiency.

Electric vehicles require specialized high-voltage wiring that is designed for safety and efficiency, ensuring reliable performance under demanding conditions.

Lightweight and eco-friendly materials, such as aluminum, are now used in wiring to improve fuel efficiency and reduce environmental impact.

Regular maintenance and the use of specialized tools are essential for diagnosing and repairing the increasingly complex wiring systems in modern cars.

The integration of IoT technology in vehicles demands advanced wiring solutions that enable remote updates and connectivity, enhancing the driving experience.

The Early Days of Car Wiring

Simple Wiring in Old Cars

Basic systems for starting and lighting

In the early 1900s, car wiring was very simple. Cars used basic electrical systems for important tasks. These systems helped start the engine and light up at night. Early cars had cloth-covered wires connecting parts like spark plugs and batteries.

Electricity moved straight from the battery to lights and ignition. The design was easy because technology was not advanced yet. Hand-drawn wiring diagrams showed only a few connections. This made repairs simple. These basic setups were the start of today’s advanced car wiring.

Few wires in early 1900s cars

At that time, cars didn’t need many wires. Vehicles were mostly mechanical, so wiring stayed simple. Early trucks and cars had similar setups with only a few wires. This made fixing problems easy for mechanics.

The small amount of wiring showed how new the car industry was. Car makers focused on strong mechanical parts, not electrical ones. Early cars used manual controls and mechanical systems, leaving little space for electrical improvements.

Problems with Early Wiring

Weak materials and no standards

Old car wiring had many problems, like weak materials and no standards. Different car makers used different designs, causing confusion. Cloth-covered wires were common but broke easily in heat or wet conditions.

Without standard connectors, fixing wires was hard. Mechanics dealt with wires of different sizes that didn’t match. This slowed down repairs and made wiring less reliable.

Few features due to mechanical focus

Cars back then didn’t have many electrical features. Wiring was only for basics like headlights and starting the engine. Things like radios or power windows didn’t exist yet.

Car makers cared more about proven mechanical designs than new electrical ideas. This made cars reliable but slowed down better wiring systems.

The Rise of Complexity in Automotive Wiring

Changes in Wire Harness Technology

Adding multi-wire harnesses for features like car radios

In the mid-1900s, car wiring became more advanced. Cars started using more electrical features, needing better wiring. Multi-wire harnesses were created to handle these new needs. These harnesses grouped wires together, making installation easier and less messy.

Car radios were one of the first new features added. They needed special wires to connect to power and speakers. Multi-wire harnesses helped add radios without overloading the car's system. This idea led to today’s modern wiring harnesses, which keep improving for complex cars.

Standard connectors for easier repairs

Standard connectors became important for better wiring systems. Before this, car wiring was not the same across brands, making fixes hard. Standard connectors solved this by making parts work together easily.

These connectors also made cars safer by preventing wrong connections. Mechanics could fix cars faster without dealing with mismatched wires. This change made car wiring more reliable and easier to maintain.

Mid-1900s Improvements

Adding fuses and relays for safety

As wiring got more complex, safety became very important. Fuses and relays were added to protect against electrical problems. Fuses stopped circuits when too much electricity flowed, preventing fires and damage.

Relays let small circuits control bigger devices safely. This made the system safer and more efficient. Adding these parts was a big step in making car wiring handle more power safely.

Wiring for power windows, air conditioning, and more

In the mid-1900s, cars got features like power windows and air conditioning. These needed more detailed wiring to work well. Wire harnesses changed to include more circuits and connectors.

Power windows used wires to link switches, motors, and power. Air conditioning needed separate circuits for fans and temperature controls. These changes showed how people wanted more comfort in their cars, and wiring improved to meet those needs.

The Digital Revolution in Car Wiring

Electronics and Data Systems Working Together

Computers, sensors, and safety features

Onboard computers changed how car electrical systems work. These computers control engine power, fuel use, and pollution levels. Sensors collect data like speed and temperature for the computer to use. Advanced Driver Assistance Systems (ADAS) depend on this teamwork. ADAS features, like lane assist and cruise control, use cameras and sensors to improve safety.

New wiring diagrams help with these changes. Modern cars have detailed diagrams showing how parts connect. These diagrams make fixing and understanding systems easier. As cars get more advanced, these tools become even more important for repairs.

CAN Bus for better data sharing

The CAN bus system improved how cars share data. It lets many car parts talk through one network, cutting down on wires. Instead of separate wires for each task, data moves quickly through the CAN bus.

This system made wire harnesses lighter and cheaper to make. Fewer wires mean fewer problems and better reliability. The CAN bus is now common in cars because it handles complex systems well. It makes car systems faster and more accurate.

Changes in Wire Harness Technology

Fewer wires with multiplexing

Multiplexing sends many signals through one wire. This reduces the number of wires needed in cars. For example, one wire can handle both music and air conditioning controls. This saves space and lowers costs.

Wiring diagrams now include multiplexing details. These diagrams show how signals move through fewer wires. They also explain how the system works with less complexity.

More features with fewer wires

Having fewer wires doesn’t mean fewer features. Cars today have voice controls, wireless charging, and software updates. These features need fast data sharing, made possible by CAN bus and multiplexing.

Interactive diagrams help keep these systems running smoothly. They show how everything connects, making repairs quicker. With fewer wires and more features, car wiring has come a long way.

Modern Innovations in Automotive Wiring

High-Voltage Systems for Electric Vehicles

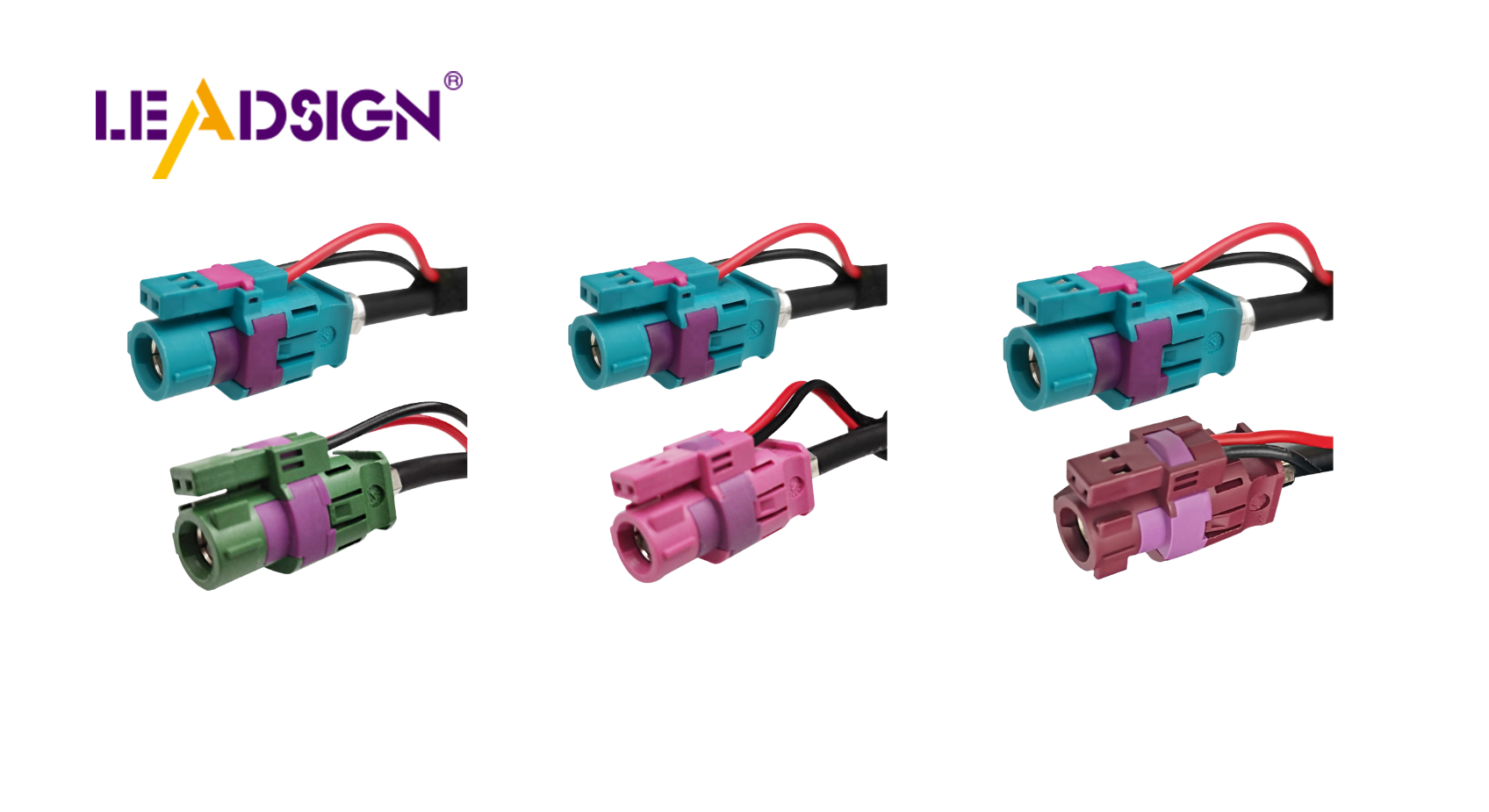

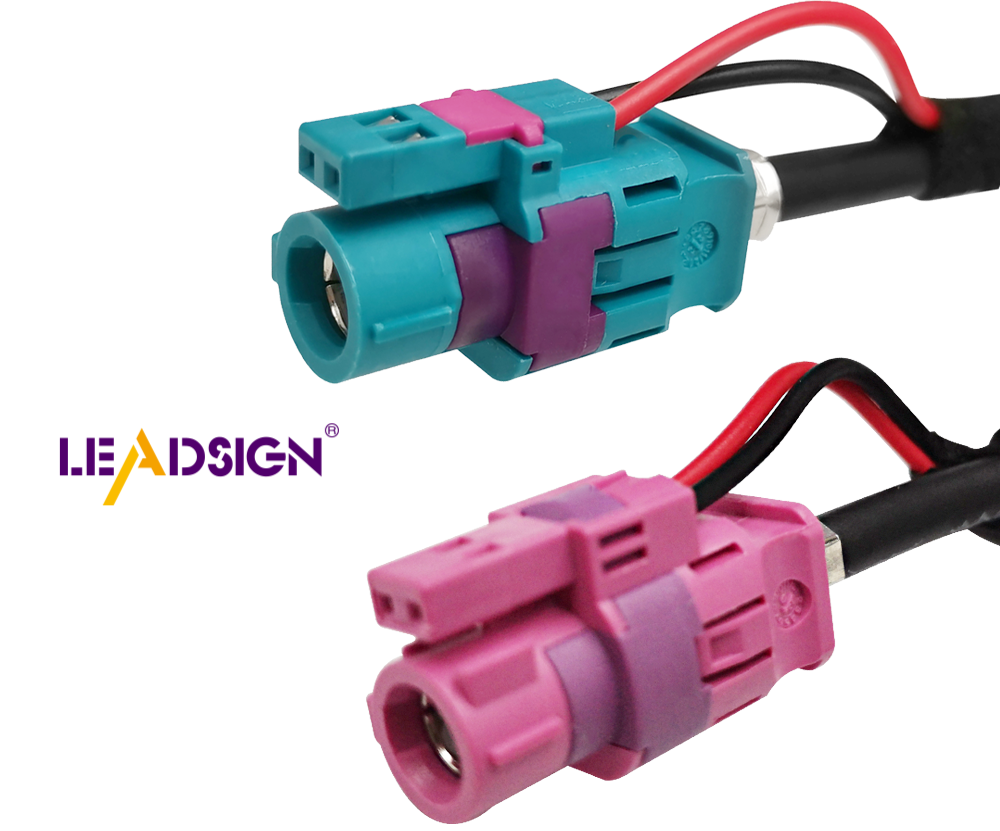

Special wires for batteries and charging

Electric cars need strong wires for power and batteries. These wires handle energy safely and work well under pressure. Special coverings keep wires cool and protect them from damage.

Car makers now use simple, modular wire designs. These designs make it easier to connect battery parts. Pre-made modules save time and fit different car models easily.

Keeping high-voltage systems safe

High-voltage wires in electric cars must be very safe. Strong coverings and tight connectors stop leaks and short circuits. Fuses and relays protect wires from too much power.

New wire designs keep wires secure in tough conditions. Strong connections prevent wires from moving or breaking. These changes make electric car wiring safer and more reliable.

IoT and Smart Vehicle Connectivity

Wires for updates and fixing problems remotely

Smart cars need special wires for updates and repairs. These updates improve car software without visiting a mechanic. New wiring methods send data quickly between cars and servers.

Strong materials in these wires keep signals steady. This helps cars stay connected and work better in all conditions.

Connecting screens and digital systems

Smart cars use advanced wires for screens and controls. These wires help features like touchscreens and voice commands work smoothly.

Fast connectors link screens to other car systems. These connectors make sure everything works together for a better driving experience.

Lightweight and Sustainable Wire Harness Technology

Using lighter and reusable materials

Car makers now use aluminum wires to make cars lighter. Aluminum is light but still carries power well. Lighter cars use less fuel and perform better.

Recyclable materials are also used to cut waste. These materials help the environment by reducing trash during production.

Making wiring eco-friendly

Eco-friendly wiring is about more than materials. Simple wire designs save energy during production. Modular designs make building and installing wires faster and easier.

New wiring ideas help cars become greener. As electric and smart cars grow, these changes will shape the future. Lightweight and eco-friendly wires are a big step forward.

Challenges and Maintenance in Modern Car Wiring

Complexity and Repair

Finding problems in complex wiring

Modern car wiring is like a complicated puzzle. Fixing issues needs special tools and knowledge of electrical systems. Technicians use detailed diagrams to find where problems are. These diagrams show how all parts connect, helping locate faults.

Using multiplexing and CAN bus systems has fewer wires but is harder to fix. One wire can carry many signals, making errors tricky to find. Technicians use scanners to read data from car computers. These tools make repairs easier but need training to use well.

Automotive Experts say, "Modern wiring must be easy to upgrade as cars get more advanced."

Special tools and skills needed

Fixing today’s car wiring needs more than basic tools. Tools like multimeters check voltage and current, while oscilloscopes test signals. These tools find problems like broken wires or short circuits.

Training is very important for working on advanced wiring. Technicians must learn about electric and hybrid car systems. This knowledge helps them fix cars correctly and avoid causing more damage.

Safety and Cost Concerns

Dangers of short circuits and fires

Safety is a big worry with car wiring. Short circuits happen when wires touch or coverings wear out. This can cause overheating or even fires. Electric cars with high-voltage systems have extra risks. Good insulation and tight connections stop these problems.

Fuses and relays protect against power surges by cutting off electricity. Regular checks make sure these parts work well. Skipping maintenance can lead to wiring failures, risking the car and its passengers.

High costs of modern wiring

New wiring systems cost more for makers and buyers. Lightweight materials like aluminum and strong insulators raise production costs. Complex wiring takes more time and effort to build.

For car owners, repairs and upgrades can be expensive. Fixing damaged wires or adding new systems needs special tools and skilled workers. Even with these costs, advanced wiring improves safety, performance, and features.

Lime Wire Customs shares, "Car wiring has grown from simple to smart, making cars safer and better.

Car wiring has greatly changed the car industry. It started with simple circuits and now supports advanced systems. These include electric engines and self-driving features. These changes make cars safer, smarter, and more efficient. In the future, electric cars and smart technology will bring more improvements. Wire harnesses will keep improving to be eco-friendly and flexible. This progress helps cars meet new technology needs and protect the environment.

FAQ

What is the history of automotive wiring systems?

The history of car wiring shows how vehicles have improved. Early cars had simple electrical systems with few circuits. These circuits powered basic things like lights and starting the engine. Wires were basic and easy to design. Copper wires were used because they worked well and lasted long. As cars added more features, wiring systems became more advanced.

How has car wiring evolved over the years?

Car wiring has gone from simple to very complex. Old cars only needed a few wires for lights and starting. Later, multi-wire harnesses were made for radios and power windows. Today, cars use systems like CAN bus to share data and cut wires. This change shows how cars are becoming smarter and more efficient.

Why is copper commonly used in automotive wiring?

Copper is often used in car wiring because it carries electricity well. It helps send power without wasting energy. Copper is also strong and doesn’t rust easily. This makes it good for long-term use in all kinds of weather. These traits make copper great for both old and new wiring systems.

What is the role of Lime Wire Customs in the evolution of automotive wiring?

Lime Wire Customs helps improve car wiring technology. They create new solutions for modern cars’ complex systems. Their work focuses on making wiring better and easier to use. Lime Wire Customs shows how the car industry keeps growing and adapting.

What challenges do modern car wiring systems face?

Modern car wiring has many challenges, like being harder to fix. Systems like CAN bus need special tools and skills to repair. Safety problems, like overheating or short circuits, need strong designs. Lightweight materials cost more, adding to the challenges for makers. Regular maintenance is also important to keep wiring safe and working well.

How do CAN bus systems improve car wiring?

CAN bus systems make car wiring better by sharing data faster. Instead of using many wires, one network connects different parts. This reduces the number of wires, making cars lighter and more reliable. It also helps systems like ADAS work quickly and accurately.

What makes electric vehicle wiring different?

Electric car wiring is special because it handles high-voltage power. These cars need strong wires for batteries and charging. The wires must stay safe in heat and tough conditions. Makers use strong covers and simple designs to make them reliable. These needs make EV wiring very important.

How does lightweight wiring benefit modern vehicles?

Lightweight wiring makes cars lighter, which saves fuel and boosts performance. Aluminum is often used because it’s light but still works well. Lighter designs also help the environment by using less energy. This makes lightweight wiring a smart choice for modern cars.

What safety measures are used in modern car wiring?

Modern car wiring uses safety features to stop problems. Fuses and relays protect circuits from overheating or too much power. Strong covers and tight connectors prevent short circuits. Regular checks keep these safety parts working well. These steps are important for both regular and electric cars.

How has the integration of IoT impacted car wiring?

IoT has changed car wiring by adding smart features. Cars now need special wiring for updates, remote fixes, and entertainment. These systems need fast and steady data sharing. Advanced wiring designs make this possible. IoT keeps pushing car wiring to do more and work better.

See Also

Maximizing Efficiency in Automotive Data Transfer Solutions

Boosting Automotive Data Flow with High-Speed Connectors

Understanding HSD Connectors in Automotive Applications

Transforming Automotive Connections with HFM Connector Benefits

Benefits of HSD Connectors for Automotive Entertainment Systems