Evaluating Wire Connectors: What You Need to Know

Wire connectors are important parts in electrical systems. They create strong and safe links between devices. Wire connectors are vital in areas like phones and cars. Each type of connector has special features for different uses. Knowing these differences helps you choose wisely. Checking wire connector types ensures good and safe electrical setups.

Understanding Wire Connectors

Types of Wire Connectors

Twist-On Connectors

Twist-on connectors are called wire nuts. They connect wires easily. Electricians use them at home. Twisting makes a strong link. The cover stops short circuits. They fit small AWG wires well.

Crimp Connectors

Crimp connectors join wires without soldering. A metal tube holds the wires tight. Squeezing it makes a lasting bond. They're used in cars and factories often. Crimp connectors are trusted by many experts.

Push-In Connectors

Push-in connectors make setup easy. You push bare wire ends inside them. Springs keep the wires in place firmly. They lessen hand strain when installing. You can see through their clear shell to check connections.

Materials Used in Wire Connectors

Plastic

Plastic is common in wire connectors for insulation and safety. It's light and cheap, good for home projects, and fights rust and damage.

Metal

Metal connectors are strong and last long, handling heat well, perfect for tough jobs, ensuring good electric flow, chosen by pros for durability.

Hybrid Materials

Hybrid materials mix plastic's insulation with metal's strength, working well everywhere, boosting safety and reliability, making them useful.

Features and Benefits of Wire Connectors

Safety Features

Insulation

Wire connectors stop shocks by covering metal parts. This keeps you safe when using them. Plastic is often used for this cover. It also stops water and dust from getting in. This helps keep the connection steady.

Fire Resistance

Fire resistance is very important for wire connectors. Good ones don't catch fire easily. Metal and some plastics help with this. They can take high heat without melting. These are great for factories and cars, keeping things safe.

Ease of Use

Installation Process

Putting in wire connectors is easy to do. Push-in types need little work; just push the wire in. Springs hold it tight, so your hands don’t get tired. Crimp types need a tool to squeeze them onto wires. Each type has its own way to install.

Compatibility with Different Wire Gauges

It’s key that they fit different wire sizes well. Twist-on connectors are good for small wires. Push-in ones work with solid or stranded wires too. Crimp connectors fit many wire sizes, making them useful everywhere.

Checking How Well They Work and Last

Wire connectors are very important in electrical systems. Knowing how well they work and last keeps connections safe. This part looks at tests and things that affect how long wire connectors last.

Testing Rules

UL Certification

UL Certification shows wire connectors are safe and good. Underwriters Laboratories (UL) checks them for safety. They test fire safety, electricity flow, and strength. Picking UL-certified connectors means they are safe to use.

IEC Standards

The International Electrotechnical Commission (IEC) makes rules for wire connectors worldwide. IEC rules look at how well they work and the environment. Connectors passing IEC tests are checked for heat, water, and electric performance. These meet global quality standards.

Lasting Long and Being Reliable

Environmental Resistance

Environmental resistance is key for connectors in tough places. Things like heat, wetness, and shaking can change how they work. For example, press connection techniques help them resist the environment better. This method squeezes metal tightly to make strong links that handle tough conditions better than regular soldering.

Wear and Tear

Wear affects how long wire connectors last. Using them a lot or bad weather can wear them out. Wire Nuts® give strong links where there's lots of shaking. Wago® Push In Wire Connectors work well where there's less shaking. Choosing the right one helps reduce wear and makes them last longer.

User Reviews and Experiences

What Users Say

Good Points

Lots of people like wire connectors for being dependable. They say they are simple to put in place. The connectors hold wires tightly. Eric Palazzolo, who started FindPigtails.com, says customers find car connectors easy to get. They quickly get the info they need. This makes them happy with the product.

Problems

Some users have trouble with fitting issues. Not all connectors fit every wire size. Installing in small spaces can be hard too. Some mention that connectors don't last long enough. These problems show why picking the right one is important.

Expert Views

Suggestions

Experts say pick wire connectors based on what you need. Think about where you'll use them. Choose ones with good covers for safety. Look for UL or IEC labels for quality checks. Picking well means connections stay strong.

Cautions

Experts say don't use wrong-sized connectors. Bad fits can make weak links happen. Weak links might cause electric problems later on. Check your connectors often for damage signs. Change worn ones fast to keep things safe.

Wire connectors are important for safe electrical links. Knowing the types, materials, and features helps you choose well. Picking the right connectors makes systems work better and need fewer fixes. Look at user reviews and expert tips to help decide. Check safety, ease of use, and how they work for good connections. Pick connectors that fit your needs best. Focus on quality and matching to make strong and lasting setups.

See Also

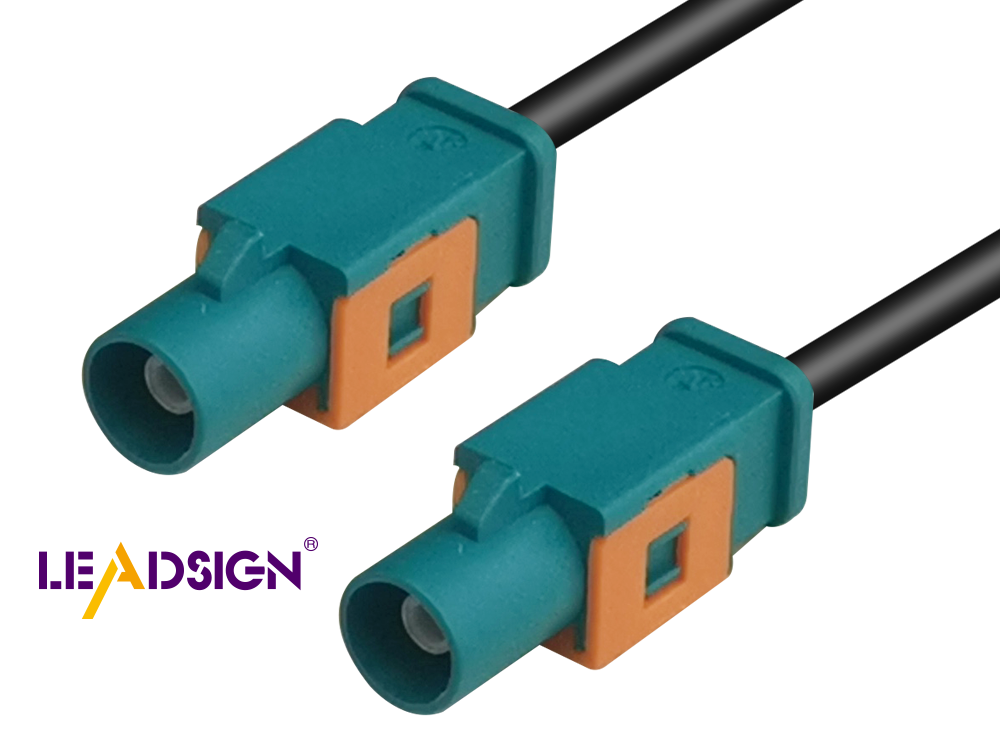

Exploring FAKRA Connectors: An Extensive Overview

Exploring Fakra Connectors: Benefits, Uses, and Setup Advice

Exploring Fakra Connectors: Fundamentals, Varieties, and Uses