3 Essential Wire Connector Types for Automotive Wire

In automotive applications, wire connector types play a crucial role in ensuring efficient electrical flow, which is essential for the proper functioning of vehicles. Poor automotive wire connectors can lead to significant issues, with approximately 45% of problems arising from contact failure. Understanding the right auto wire connectors helps prevent these issues. There are three main types used in vehicles, each offering specific advantages for automotive wires. Choosing the appropriate connector enhances vehicle safety and reliability.

Importance of Choosing the Right Wire Connector

Ensuring Safety and Reliability

Preventing Electrical Failures

Picking the right wire connector stops electrical problems in cars. Good connectors keep parts connected well. Pigtail connectors help engines work properly. Correct connectors lower contact failure risk, avoiding safety issues. Checking and maintaining connectors prevent dangers.

Enhancing Vehicle Performance

Right connectors boost car performance by allowing good electrical flow. Real connectors that match maker rules give best safety and reliability. Strong connectors handle tough conditions, keeping cars safe. Using correct connectors for jobs makes cars work better.

Compliance with Industry Standards

Meeting Automotive Regulations

Connectors must follow car rules for safety and performance. OEM wire connectors are cheap and meet standards. These improve safety, reliability, and last long in tough places. Following rules keeps cars running safely.

Ensuring Compatibility with Vehicle Systems

Matching vehicle systems is key for wire connector function. Good connections fit specific needs for safe use. Makers should not use weak connector copies. Real connectors keep contacts working, stopping issues like steering or brake failures.

Essential Wire Connector Types for Automotive Wire

Crimp Connectors

Features and Benefits

Crimp connectors are easy to use for car wires. They squeeze onto the wire tightly. This makes a strong bond that stays in place. Crimp connectors work well even when cars shake or move. They last long and stay stable in tough conditions.

Common Applications in Automotive Wiring

Crimp connectors are used a lot in cars. Mechanics connect wires with them in engines and lights. They fit into small spaces, perfect for tricky setups. Crimp connectors keep car wires working by staying connected.

Solder Connectors

Features and Benefits

Solder connectors join wires forever. Solder melts around the wire, making it solid and firm. These connectors let electricity flow well and don't rust easily. That's why they last long in cars.

Specific Uses in Automotive Systems

Solder connectors are used where reliability is key. Experts use them for engine controls and sensors. They make sure car wires work without stopping. These connectors stop electrical problems from happening.

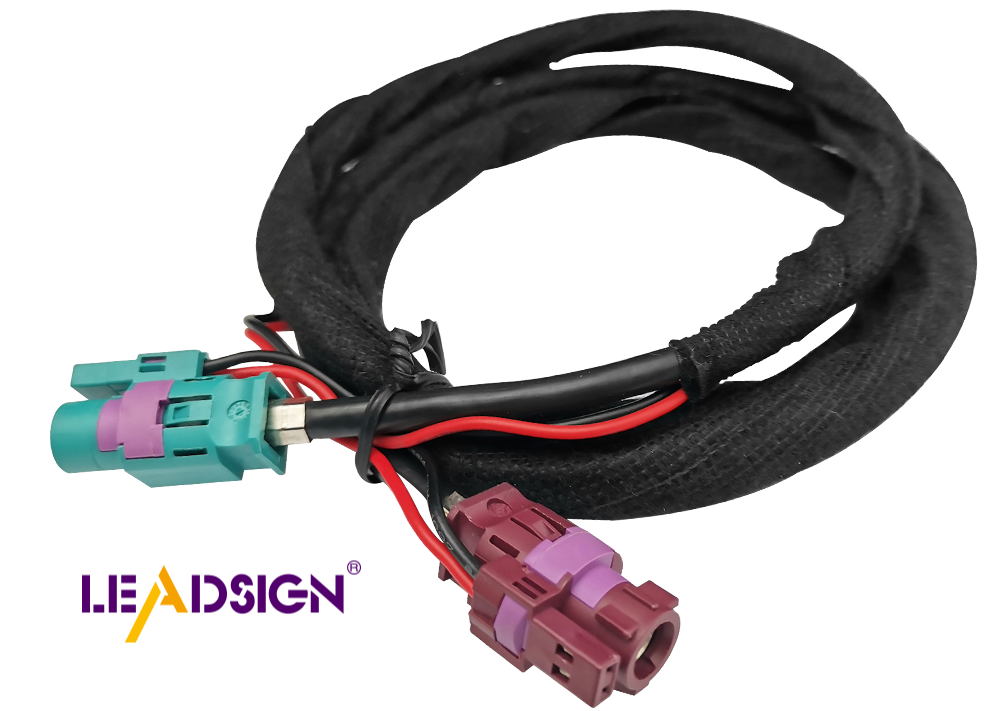

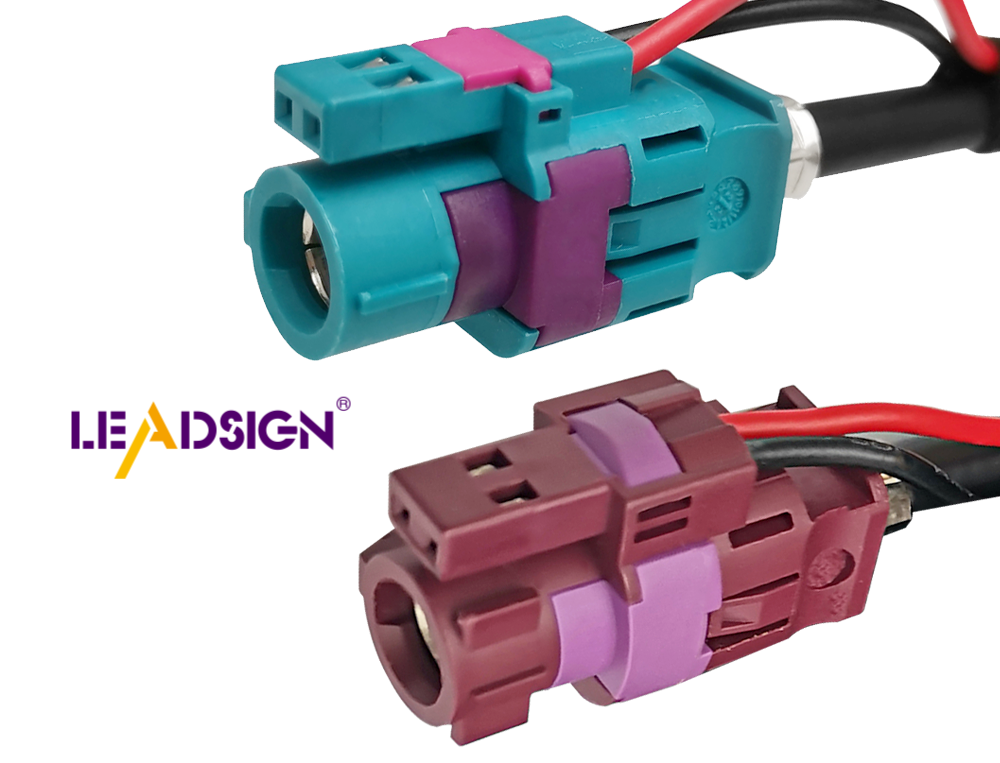

HSD Connectors

Importance in High-Speed Data Transmission

HSD connectors help send data fast in new cars. They fit many wire types, so they're useful everywhere. HSD connectors help send data fast. HSD keeps signals clear, important for smart systems like driver aids.

Compliance with Industry Standards

HSD meets car rules to work right inside vehicles. They follow USCAR-2 rules, fitting into vehicle systems well. HSD meets car rules. HSD is crucial for communication systems in cars today.

Practical Uses and Situations

Real-Life Examples

Use in Today's Cars

Today's cars need different wire connectors. These keep electrical systems working right. Crimp connectors are used in engines. They hold wires tight in small spaces. Solder connectors are for engine controls. They make strong bonds for key parts. HSD connectors help send data fast. Driver-assist systems use them for clear signals.

Stories of Connector Problems and Fixes

Bad connectors can cause big car problems. Low-quality ones might fail electrically. One story is about a car that stalled often. Bad crimp connectors were found in the ignition. Changing to good ones fixed it. Another car had infotainment issues. The problem was weak HSD connectors. Switching to better HSD ones fixed it. These show why picking the right connector matters.

Choosing the right wire connectors keeps cars safe and working well. Good connectors stop problems and make them reliable. Think about heat and wetness when picking connectors. Taking care of them makes them last longer. Using the best ones saves money on repairs. Crimp, solder, and HSD connectors each have special uses for car wires. Pick wisely to keep cars running safely and smoothly.

See Also

Exploring HSD Connectors in Automotive Technology

Significance of FAKRA Connectors in Auto Sector

The Vital Role of FAKRA Connectors in Auto Uses