Essential Tips for Automotive Electrical Connectors Types

Understanding automotive electrical connectors types is crucial for effective car maintenance. These connectors ensure the smooth operation of a vehicle's systems. There are various types designed for specific applications. Blade connectors are commonly used for general wiring, while FAKRA connectors are essential for applications like GPS. Selecting the appropriate connector is vital for optimal performance and safety. Using the correct type prevents issues such as poor connections, which can arise from improper crimping or soldering.

Understanding Automotive Electrical Connectors

Basics of Electrical Connectors

Definition and Function

Electrical connectors are key in car systems. They link two parts without losing power or signals. These connectors help your car's electrical parts work well. It's important they are reliable, so makers promise they meet standards.

Common Materials Used

Car electrical connectors use different materials. Metals like copper and aluminum are common because they conduct electricity well. Plastic is used to cover and protect them since it lasts long and resists weather. These materials help connectors survive tough car conditions.

Types of Automotive Electrical Connectors

Blade Connectors

Blade connectors are very common in cars. You use them for basic wiring jobs. They have a flat piece that fits into a slot, making it easy to connect or disconnect when needed.

Ring and Spade Terminals

Ring terminals make strong connections with screws or bolts. Spade terminals let you disconnect quickly. Both types are popular because they work well and are easy to use.

Butt Connectors

Butt connectors join two wires together securely. Use them to fix or lengthen wires. Crimping these connectors keeps out water and dirt, ensuring smooth current flow.

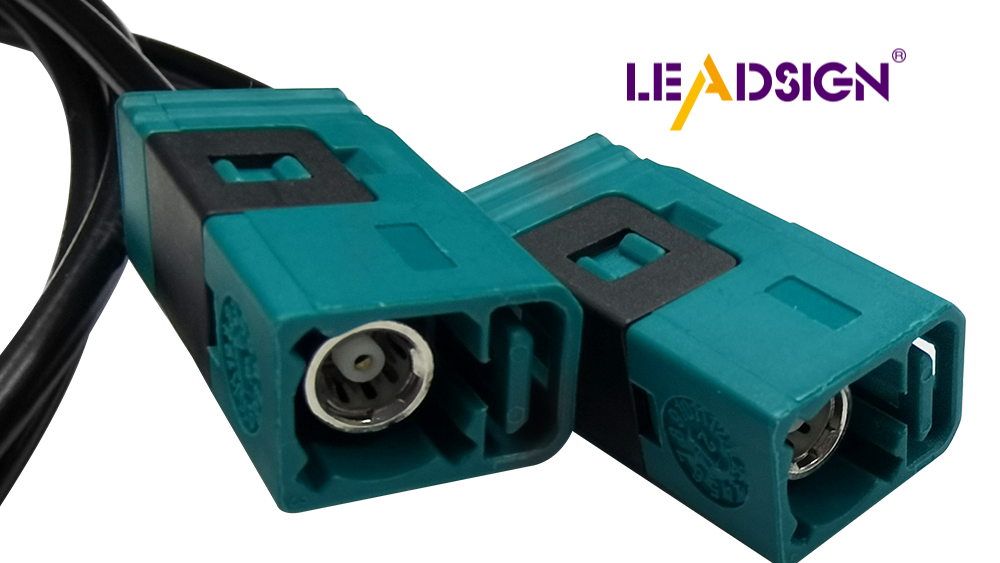

FAKRA connectors work in high-frequency car systems like GPS or radios. They meet strict car industry needs with strong, safe connections using special locks to prevent mistakes.

FAKRA connectors work in high-frequency car systems like GPS or radios. They meet strict car industry needs with strong, safe connections using special locks to prevent mistakes.

Tips for Picking the Right Connector

Things to Think About

Electrical Load Needs

Pick a connector that fits the power it will carry. Each one can handle only so much current. If it's too small, it might overheat or break. Always check if it matches what you need.

Weather Conditions

Weather matters when picking connectors. Check where they will be used. If there's water or heat, use special ones with coatings. These protect against rust and damage.

Expert Advice for Choosing Connectors

Fit Connector to Wire Size

Make sure the connector fits the wire size well. A bad fit can cause poor power flow and danger. It should match snugly to work best.

Use Dielectric Gel for Water Safety

Put dielectric gel on connectors to keep water out. This stops rust and helps them last longer in wet places.

Expert Opinion: PEI-Genesis Experts say picking the right connector is key. They help with choosing contacts, packaging, and connection methods. This shows how important careful choice and expert help are for good connections.

Tools and Techniques for Connector Installation

Important Tools

Crimping Tools

Crimping tools are important for safe car connections. They squeeze a connector onto a wire tightly. This keeps out water and dirt, stopping rust. Choose crimping tools that adjust for different wires. Good ratcheting crimpers give steady pressure, making strong connections every time.

Soldering Equipment

Soldering tools are also needed for connectors. A soldering iron melts solder to join wires and connectors. This makes a strong bond that handles shaking and moving well. It's great in wet or salty places because it seals better. Get a soldering iron with adjustable heat and different tips for various jobs.

Installation Methods

Crimping vs. Soldering

When putting in connectors, pick between crimping or soldering. Each has good points. Crimping is quick and seals tight, perfect for tough spots. It's more regular, lowering the chance of failure. Soldering costs less and needs fewer tools but takes longer and can be tricky if done wrong. Inside cars, crimping works fine; near engines, solder might be best.

Making Sure Connections Are Safe

To make sure connections are safe:

Strip the Wire: Take off some insulation from the wire's end to show metal.

Twist the Wires: Twist bare wires together to make them firm before connecting.

Use Heat Shrink Tubing: Put heat shrink tubing over the connection before you crimp or solder it. Heat it after connecting to protect from water and dirt.

Check the Connection: After finishing, check by pulling gently to see if it's secure.

Using proper tools and methods gives you strong car electrical connections.

Practical Uses and Fixing Problems

Knowing about automotive electrical connectors types helps you use them well. This part shows how to use them in real life and fix problems so your car's electric system works right.

New Wiring Kits

Good Points and Things to Think About

New wiring kits let you change your car's electric system. They help add new things or fix bad wires without changing the original setup. When picking a kit, make sure it fits your car model. Check if it supports the automotive electrical connectors types you need. This makes sure everything fits well and works best.

How to Install

Putting in a new wiring kit needs care. Follow these steps for success:

Read the Guide: Start by reading the guide from the maker carefully. It tells what your kit needs.

Get Tools Ready: Gather all tools like crimpers and soldering gear for smooth work.

Unplug Battery: Always unplug the battery before working to stop accidents.

Plan Wire Path: Plan where wires go to avoid sharp edges and heat spots.

Check Connections: Use right automotive electrical connectors types for tight connections.

Moving the Battery

Why It's Important

Moving the battery can balance weight better and clear space under the hood. This change helps handling and adds room for more parts. Pick connectors that handle longer distance and weather when moving it.

Steps to Move It

Follow these steps to move your car's battery:

Pick a Spot: Choose a place like the trunk that's stable and safe from weather.

Measure Cables: Measure cables so they reach without pulling tight.

Use Battery Box: Secure battery with a box against shakes and wetness.

Attach Cables: Use strong automotive connectors matching wire size for best work.

Check System: Test after setting up to ensure all connections are good.

Fixing Usual Problems

Finding Bad Connections

Bad connections can cause electric problems. Look at each connector for rust, wear, or breaks using a multimeter for checks on flow of electricity.

Fixes and Prevention Steps

Fixing bad connections means doing this:

Clean Connectors: Use cleaner safe for plastic to remove dirt from connectors improving their work.

Swap Broken Parts: Change any broken parts with ones that fit your system type of connectors used before.

Use Gel Protection: Put gel on connectors stopping future rust by keeping moisture away.

Do Regular Checks: Often check your car’s electric system which stops issues early making parts last longer.

Knowing about automotive electrical connectors helps keep your car running well. You found out about different connector types, what they're made of, and how they are used. Picking and installing them right makes sure they work safely. Always pick the correct connector for your job and use the right tools.

Remember: Connectors must be reliable for electronics to work right. Both soldering and crimping make strong connections if done properly.

Use these tips to improve your car's electrical system for the best performance.

See Also

The Significance of FAKRA Connectors in Auto Applications

The Fundamentals of HSD Connectors in Auto Sector

The Manual for Ford Fakra Connectors

The Significance of Fakra Auto Connectors in Contemporary Cars