The Essential Guide to Automotive Plugs and Connectors

Vehicle connectors are very important for your car's electric system. They help power and signals move well, which keeps car parts working smoothly. A car has about 240 connectors, so knowing their types is key for good performance and safety. These vehicle connectors are part of important safety systems like airbags and ABS, showing how crucial they are. As technology gets better, strong wire-to-wire connectors are needed more, especially in ADAS and electric engines. By understanding these parts, you can see how they affect your car's reliability and safety.

Key Takeaways

Understanding the types of vehicle connectors—like blade, bullet, and butt connectors—can enhance your car's performance and safety.

Regularly check and maintain your connectors to prevent issues like flickering lights or power loss, ensuring your car runs smoothly.

Choose connectors that fit your car's electrical needs, considering factors like current limits and weather resistance for optimal performance.

Proper installation of connectors is crucial; use the right tools and follow a step-by-step guide to ensure secure connections.

Be proactive in spotting signs of bad connectors, such as flickering lights or dashboard warnings, to address problems before they escalate.

Utilize a multimeter and diagnostic tools to troubleshoot connector issues effectively, ensuring your car's electrical system remains reliable.

Regular cleaning and greasing of connectors can extend their lifespan and maintain a strong connection, enhancing overall vehicle safety.

Understanding Vehicle Connectors

Vehicle connectors are key in a car's electric system. They help power and signals move between parts. Knowing connector types helps keep your car working well.

Types of Connectors

Blade Connectors: These are flat and thin like blades. They're used in cars because they're easy to use and connect tightly. They're great for tight spaces.

Bullet Connectors: Shaped like bullets, these make strong wire connections. They're often in car wiring, letting you disconnect quickly.

Butt Connectors: These join two wires end-to-end. They're important for making wires longer or fixing breaks. Butt connectors keep connections strong.

Ring and Spade Terminals: These link wires to a stud or screw. Rings make a full circle, while spades have an open end, so they're easy to put on and take off.

Functions and Applications

Power Transmission: Connectors move power from the battery to parts like the engine and lights, making sure they work right.

Signal Transmission: They also send signals between electronic parts, which is important for things like sensors and GPS.

Grounding and Safety: Good grounding is needed for safety and performance. Connectors help with this by making secure ground links.

Common Locations in Vehicles

Engine Compartment: Many connectors are here, linking parts like the alternator and sensors so the engine runs well.

Interior Electronics: Inside the car, connectors join systems like stereo and climate control for smooth operation.

Lighting Systems: Connectors are crucial for lights to get power and signals so headlights work right.

Knowing about vehicle connectors shows how they keep your car safe and efficient. Checking them often keeps your car reliable.

Important Things to Think About When Picking Connectors

When picking car connectors, think about key things for best performance and safety. These tips help you choose well, making your car's electric system work better.

Electrical Needs

Current and Voltage Limits

Check how much current and voltage connectors can handle. This tells you the power a connector can take. Right ratings stop overheating and keep power flowing well. This is important for your car's electric parts to work right.

Fit with Car Systems

Make sure the connectors fit your car's systems. Different cars have different setups, so matching them is a must. This fit makes everything work smoothly and stops electric problems.

Weather Conditions

Weather Proofing

Think about how connectors handle weather. Cars face rain, snow, and dust often. Good weather-proof connectors protect from these things, lasting longer. Sealed ones are great at this job.

Heat Handling

How well connectors handle heat is key too. They need to stay strong in hot or cold without failing. Good ones work in all temperatures, keeping your car reliable.

Material Strength

Rust Protection

Pick connectors that don't rust easily. Rust weakens links and causes electric issues. Metal ones are tough and last long in cars.

Strong Build

Connectors need to be strong to stay connected well. Tough ones resist shaking and stress common in cars. This strength keeps connections tight, helping your car run smoothly.

By thinking about these points, you pick connectors that make your car safe and efficient. Regular checks keep them working their best, helping your car's electric system run smoothly.

Installation and Maintenance Tips

Installing and taking care of car connectors helps them last longer. Doing it right keeps your car's electric parts working well.

How to Install Correctly

Putting in connectors the right way is important. Here's how you do it:

Tools You Need

To put in connectors, get these tools ready:

Wire cutters

Crimp tool

Heat shrink tube

Soldering iron (if needed)

Multimeter for checking

These tools help you install easily and correctly.

Step-by-Step Guide

Get Wires Ready: Use wire cutters to remove the plastic from wire ends. Make sure enough wire is showing for a good link.

Pick the Right Connector: Choose a connector that fits the wire size and job. This makes sure it fits well and works right.

Crimp the Connector: Put the bare wire into the connector and crimp it tight with a tool. Tight crimps stop loose links.

Use Heat Shrink Tube: Slide heat shrink over the link, then heat it up to shrink it down. This adds extra cover and keeps water out.

Check Connection: Use a multimeter to test if it's connected well. This step checks if everything works fine.

Follow these steps to install connectors right and keep your car's electric system strong.

Best Ways to Maintain Them

Taking care of car connectors stops problems and makes them last longer. Here’s what to do:

Look Over and Clean Often

Check connectors often for damage or wear signs like rust or loose wires. Clean them with a soft brush or air spray to clear dirt away, keeping them working well.

Keep Connections Tight

Make sure all connections are tight but not too tight, which can break them. Loose ones cause electric problems or danger. Use grease on them to keep moisture away, making them last longer.

By following these tips, your vehicle connectors stay in top shape, helping your car stay safe and work well.

Fixing Common Problems

Car connectors are key for your car's electric system. If they break, you might have problems. Finding and fixing these fast keeps your car running well.

Spotting Issues

Signs of Bad Connectors

Bad connectors show clear signs. You may see flickering lights or lose power in gadgets. Sometimes, the engine won't start, or warning lights flash on the dashboard. These signs mean connector problems need fixing.

Tools and Ways to Check

To find connector issues, use certain tools and ways. A multimeter checks if power flows right. Look closely for rust or damage. A diagnostic scanner finds error codes about electric faults. These help find the exact problem.

Fixes and Repairs

Changing Broken Connectors

When a connector is broken, change it quickly. First, disconnect the battery to stay safe. Take out the bad connector with proper tools. Put in a new one by following earlier steps. This fixes the link and solves the problem.

Steps to Stop Future Problems

Steps can stop future connector troubles. Regular care is important. Check connectors for wear or rust signs often. Clean them to remove dirt and dust regularly. Use grease to keep moisture away from them. These actions make connectors last longer and work better.

Expert Advice:

The Car Electrical Plug Connectors Guide says, "Regular care and quick fixes help plug connectors work well and keep a car's electric system running smoothly."

By knowing common connector problems, you keep your car reliable and working well. Good care and timely fixes keep your car's electric parts in top shape.

Picking the right car connectors is very important. Good connectors keep your car safe and working well. They help with new car tech too. Clean them and check them often to make them last longer. Fix problems quickly to stop flickering lights or other issues. For more info, look for guides on car connectors. By learning more and acting fast, you keep your car running smoothly and reliably.

See Also

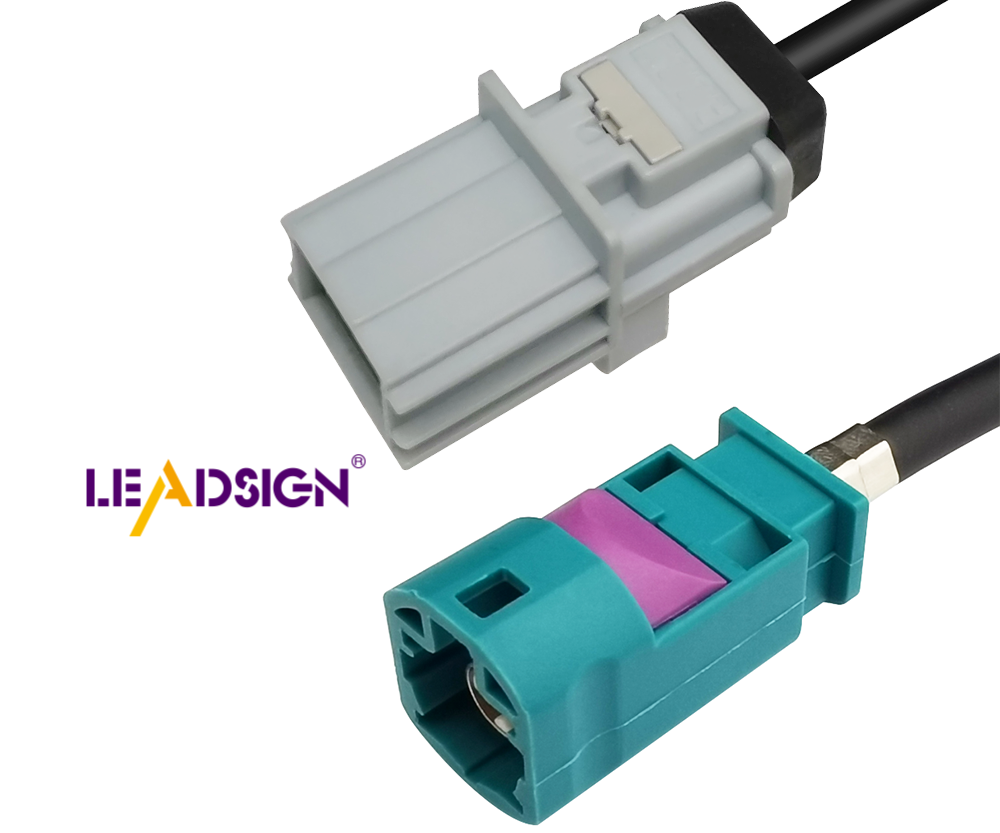

Exploring Ford Fakra Connectors: Your Essential Guide

A Complete Overview of the Fakra Plug

Fundamentals of HSD Connectors in Automotive Applications