Essential Car Wire Connector Types You Should Know

Understanding the types of wire connectors automotive is crucial for anyone working with vehicles. These connectors ensure that a car's electrical components function efficiently. They provide secure and robust connections, essential for the proper operation of various automotive systems. Different types of wire connectors automotive are designed for specific tasks, ensuring each connection is reliable and safe. By familiarizing themselves with these connectors, individuals can enhance their skills in repairing and maintaining vehicles.

Basics of Car Wire Connectors

Definition and Function

What are wire connectors?

Wire connectors are important in cars. They join wires to keep connections strong. These come in many shapes and sizes. Each is made for a special job. Using the right one stops electrical problems and keeps the car running well.

Why are they important in cars?

In cars, wire connectors are key. They help signals move between parts smoothly. Without them, systems might break down. For example, they link the battery to start the engine. They also connect lights and radios so they work properly.

Historical Evolution

Early developments in automotive connectors

Car connectors started in the early 1900s. At first, simple ones were used but broke easily. As cars got complex, better ones were needed. Makers tried new materials and designs to make them last longer.

Modern advancements and innovations

Today’s car connectors are much better. They use strong materials that handle heat and shaking well. New designs help them work longer without breaking apart by accident. This makes sure modern cars run safely and efficiently.

Types of Car Wire Connectors

Knowing car wire connectors is important for fixing cars. They help electric parts work well and safely. Let's look at some common types.

Butt Connectors

Features and Uses

Butt connectors join two wires together. They are round and often made of copper, which conducts electricity well. These are great for fixing or adding wires in cars. Their shape makes a strong link, stopping electric problems.

Installation Tips

To use butt connectors, remove the plastic cover from wire ends. Put each wire in the connector and squeeze it tight with a tool. This makes sure they stay connected. Gently pull on wires to check they are secure.

Bullet Connectors

Features and Uses

Bullet connectors make connecting and disconnecting wires easy. They have a male and female end that fit together tightly. These are used in car wiring where parts like lights need frequent changes.

Installation Tips

When using bullet connectors, match the male and female ends right. Take off the wire covers and put them into the connectors. Use a tool to tighten them together. Test by slightly pulling apart to see if they stay linked.

Spade Connectors

Features and Uses

Spade connectors, also called fork connectors, attach easily to screw terminals. They are used in cars where wires connect to blocks or relays quickly.

Installation Tips

For spade connectors, strip wire ends then insert them into the connector. Squeeze it tight with a tool to hold the wire firm. Attach by loosening a screw, placing under it, then tightening again to keep it steady.

Ring Connectors

Features and Uses

Ring connectors are important in car wiring. They wrap around a bolt to hold wires tight. These are often made from copper, which is strong and conducts electricity well. Solderless Terminal, Multi-Stud Ring and Solderless Terminal, Ring Terminal are popular because they are easy to use.

Ring connectors come in different sizes and colors. This helps you pick the right one for your wire size. In cars, they connect batteries and ground wires where strong links are needed.

Installation Tips

To install ring connectors, follow these steps:

Strip the Wire: Take off the plastic cover at the end of the wire. Make sure it fits the connector size.

Insert the Wire: Put the bare wire into the ring connector's barrel fully.

Crimp the Connector: Use a tool to squeeze the barrel tight around the wire.

Attach to Terminal: Place it over a bolt or screw, then tighten it up.

Inspect the Connection: Check if it's secure by gently pulling on it.

By doing this, you can use ring connectors well in car repairs.

Installation Techniques

Tools Needed

Important tools for setup

To put in car wire connectors, you need the right tools. These tools help make sure connections are strong and safe. Here are some important ones:

Wire Strippers: They take off the plastic cover from wire ends without harming the wire.

Crimping Tool: This tool squeezes the connector onto the wire for a snug fit.

Screwdriver: Needed to attach connectors like spade or ring terminals to screws.

Multimeter: Checks if electrical connections work well and have no problems.

Safety steps

Safety is very important when working with car wires. Here are some safety tips:

Wear Safety Gear: Use gloves and glasses to guard against shocks and flying bits.

Disconnect Battery: Always unplug the car battery before starting work to avoid shocks.

Work in Bright Light: Make sure your area is bright so you don’t make mistakes.

Check Wires for Damage: Look at wires closely before connecting them to stop future issues.

How-To Guide

Getting wires ready

Getting wires ready is key for good installation. Do these steps:

Cut Wire: Use cutters to trim the wire to needed length.

Strip Insulation: Take off about half an inch of cover using strippers.

Twist Wire Ends: Twist bare wire strands together so they go into connectors easily.

Joining wires

After prepping, join wires with right connectors:

Pick Right Connector: Choose one that fits wire size and job. For instance, use color-coded Ring Terminals for easy cable size match.

Put Wire In Connector: Insert stripped end into connector barrel.

Crimp Connector Firmly: Use crimper tool to press connector onto wire tightly.

Making connection secure

Once joined, secure it well so it stays stable:

Attach To Terminal: For things like a Solderless Terminal, Ring Terminal, place over bolt or screw then tighten firmly.

Check Connection Strength: Gently tug on wire to see if it holds tight.

Test With Multimeter: Ensure connection works fine with no faults by testing it.

By doing these steps, people can set up car wire connectors properly, making sure car systems run smoothly and safely.

Q&A: Common Problems and Care

Fixing Usual Issues

Finding Bad Connections

Finding bad connections in car wires is hard. Mechanics often struggle to see if a connector works right. Just looking might not show problems like loose pins. Automotive technicians say using the right tools is key to check connections. For example, don't use a paperclip in a terminal as it can break things. Special probes keep the circuit safe.

"I can't count how many times I asked a tech, 'Is the connector ok?' and got 'Yup, looks ok.' Often, pin-fit issues aren't visible; you need tools to find them." - Automotive Technician

Fixes for Usual Problems

To fix common problems, mechanics should use tiny wires for tests. This helps find issues without more damage. For instance, using a wire piercing plug shows if a connection is weak fast. Once found, swapping the bad wire or terminal fixes it.

"I learned long ago to use the smallest conductor you can for a back probe test." - Automotive Technician

Care Tips

Routine Check-Ups

Regular checks are vital for keeping car wire connectors good. Mechanics should often look at connections for wear or harm signs. Tools like UMicroBackProbe help by giving exact tests during checks. Regular looks stop future troubles and keep car electric parts working well.

"Figure 5 shows another set of tools that I believe is crucial to electrical testing, again from AESwave: the Utest Advanced Terminal Test Kit." - Automotive Technician

Best Ways for Long Life

To make car wire connectors last longer, follow best ways. Always unplug the car battery before working on electric parts to avoid shocks. Use correct tools like wire strippers and crimpers for tight links. Also, having bright light reduces mistakes when installing or fixing.

By following these tips on fixing and care, people can handle car wire connectors well, ensuring safe and reliable cars.

Knowing about car wire connectors is important for fixing cars. They help car systems work well. By learning about them, people can get better at fixing and taking care of cars. Using this knowledge makes cars safer and more reliable.

"Pin-fit problems are common and hard to fix," says Tech Expert. Good tools are needed to find these issues.

Readers should ask questions and share thoughts to help everyone learn and improve together.

See Also

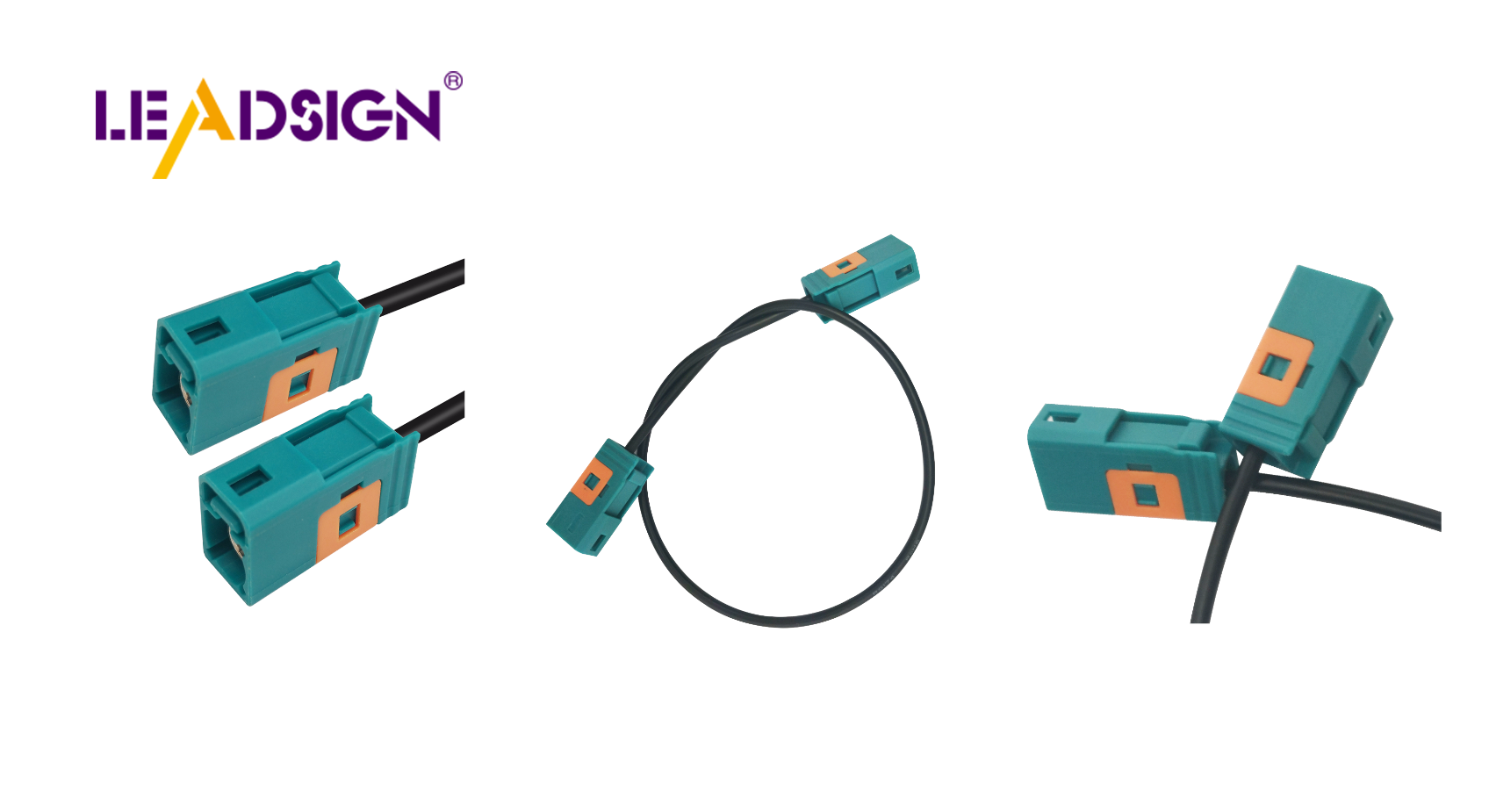

Exploring Fakra Connectors: Fundamentals, Varieties, and Uses

Understanding HSD Connectors in Automotive Sector

Significance of FAKRA Z Connectors in Auto Uses