Essential Automotive Wire Connectors for Every Mechanic

Automotive wire connectors types are very important in car repair. They help electrical systems work safely and well. Without good connectors, you could have short circuits or bad wiring. These problems happen with weak connectors that don't crimp tightly. Good connectors made of thick copper or brass stop voltage drops and heat. This keeps current flowing well and lowers the chance of electrical problems. Knowing different wire connector types, such as crimp connectors, bullet connectors, spade terminals, and heat shrink connectors, helps avoid these issues and keeps your car reliable.

Understanding Wire Connectors

What Are Wire Connectors?

Definition and Purpose

Wire connectors are very important in car electrical systems. They connect wires to keep them safe and steady. You might call them wire nuts. These connectors stop live wires from being open, keeping you safe from shocks. By stopping wires from touching bad surfaces, they protect your car's electrical system.

Common Materials Used

Different materials make up wire connectors. Copper or brass is often used because they carry electricity well. These metals help avoid losing power and getting too hot. Some connectors have plastic or rubber covers for extra safety. This mix of materials makes them strong and good for cars.

Why They Are Essential

Ensuring Safety

Safety is key in fixing cars. Wire connectors help by stopping short circuits and fires. For example, butt connectors join two wires end-to-end to keep them tight together. This stops loose wires from causing problems. Also, bullet connectors let you quickly disconnect wires safely when needed.

Enhancing Efficiency

Efficiency saves time when fixing cars. Wire connectors do this by giving strong connections that need little care. With things like butt connectors, you get a lasting connection that doesn't need many checks or fixes. Using the right ones keeps electricity flowing well so your car works smoothly.

Types of Automotive Wire Connectors

Knowing about different wire connectors is important for mechanics. Each one has a special job and benefits. Let's look at some common types.

Butt Connectors

Features and Uses

Butt connectors join two wires end-to-end. They make a strong connection, which is important in cars. Use them to make wires longer or fix broken ones. They come in many sizes to fit different wires.

Installation Tips

To install butt connectors, be careful. First, take off the plastic from the wire ends. Put each wire into the connector until they touch inside. Use a crimping tool to squeeze it tight. This stops loose connections that can cause problems.

Ring and Spade Terminals

Differences and Applications

Ring and spade terminals are popular in cars. Ring terminals are circles you secure with bolts or screws. Spade terminals look like forks, easy to put on and take off. Use ring terminals for permanent connections; spades for ones you change often.

Best Practices for Use

Make sure the wire size matches the terminal size for good fit and flow of electricity. Crimp the terminal onto the wire tightly but don't break it. Check by gently pulling on the wire.

Quick Disconnects

Advantages

Quick disconnects are handy and fast to use. They let you connect or disconnect wires without tools easily, useful when changing parts often.

Common Scenarios for Use

You see quick disconnects in car lights, sound systems, and other parts needing regular care because they are easy to use quickly.

By knowing these connector types, you can fix things safely and well. Each type has its own features, so pick the right one for your needs.

Other Types of Automotive Wire Connectors

Bullet Connectors

Bullet connectors are special because of their unique shape. They have a male and female end that fit tightly together. This makes a strong connection. You use bullet connectors when you need to connect and disconnect wires often. For example, they work well for speaker wires in car audio systems.

Installation Tips:

Take off the plastic from wire ends before putting them in.

Use a crimping tool to make sure the connection is tight.

Check by gently pulling on the wires to see if they stay put.

Expert Opinion: "Bullet connectors are great for connections that change often. Their design helps stop accidental disconnections," says an electrical expert.

Heat Shrink Connectors

Heat shrink connectors are important too. They keep water out, so they’re good for wet or hot places. You find these connectors useful in engines or spots needing weather protection.

Advantages:

They protect against rust and keep electricity safe.

The heat shrink tube seals tight, stopping water from getting in.

They come in different sizes to fit various wires.

Installation Steps:

Strip wire ends and put them into the connector.

Secure with a crimping tool.

Heat the tubing evenly until it shrinks around the wire.

Expert Insight: An engineer says, "Heat shrink connectors are key for car parts needing strength and weather safety."

By knowing these types of automotive wire connectors, you can choose wisely when fixing or improving car electrical systems. Each type has its own perks, making sure you have what you need for any task.

Picking the Best Connector

Things to Think About

Choosing the right wire connector is very important. It keeps your car's electrical systems safe and working well. Here are some things to think about:

Wire Size Match

Wire size match matters a lot when picking connectors. The connector must fit the wire size well. If it's too big or small, it might not connect right. This can cause electrical problems. Always check the wire size before choosing a connector.

Weather Conditions

Weather conditions affect how connectors work. If you work where it's wet, hot, or has chemicals, choose strong connectors for those places. Heat Shrink Bullet Connectors are great here. They keep water out and hold wires tight, perfect for cars, bikes, and boats.

Strong and Lasting

Good quality and lasting power of connectors affect how long they last and work well. Focus on these:

Material Choices

Good materials make strong connectors. Look for ones made from copper or brass because they carry electricity well and don't rust easily. Bullet Connectors use good materials for strong connections that last long. They have two parts that snap together easily.

Brand Picks

Picking connectors from good brands helps them work better and last longer. Good brands use top materials and ways to make them. Buying from trusted brands means you get a good product that works well in tough car jobs.

By thinking about these things, you can pick the best wire connectors for your needs, keeping your car's electrical systems safe and working smoothly.

Practical Tips for Mechanics

Installation Techniques

Tools Needed

To put in wire connectors right, you need good tools. Here’s a list:

Wire Strippers: These take off the plastic from wires without harm.

Crimping Tool: This tool makes sure the connector is on tight.

Heat Gun: Use this for heat shrink connectors to seal them well.

Multimeter: Check if everything works with this tool.

Having these tools helps make your work easier and faster.

Step-by-Step Guide

Here’s how to install wire connectors:

Strip the Wire: Take off about half an inch of plastic from wire ends.

Insert into Connector: Put the bare wire into the connector till it hits metal.

Crimp the Connector: Squeeze it tight with a crimping tool for strength.

Check the Connection: Pull gently on the wire to see if it's secure. Re-crimp if needed.

Seal with Heat Shrink (if needed): Use a heat gun to shrink tubing around wires for waterproofing.

Follow these steps for safe and strong connections every time.

Maintenance and Troubleshooting

Common Problems

Even when done right, problems can happen. Here are some common ones:

Loose Connections: Happens if wires aren’t crimped tightly enough.

Corrosion: Water can make connectors rust, especially in tough places.

Voltage Drops: Bad connections can lower voltage, hurting performance.

Spotting these early stops bigger issues later.

Fixes and Prevention

Try these solutions:

Re-crimp Loose Connections: If loose, use a crimper again to tighten it up.

Use Heat Shrink Connectors: They keep water out and stop rusting.

Regular Checks: Look at connections often for wear or damage signs.

Pick Quality Connectors: Choose thick brass ones for strong holds and less voltage drop.

By keeping up with care and fixing issues fast, your car's electrical systems will stay reliable and work well.

Picking the right wire connectors is very important. Good connectors keep your car safe and working well. They help avoid electrical problems. Spending on strong connectors saves time and money later.

An experienced mechanic says, "Keep learning new skills." Knowing the best tools helps you fix things better. Always choose quality and practice to make sure connections last long.

See Also

Significance of HSD Connectors in Automotive Sector

Fundamentals of HSD Connectors in Auto Sector

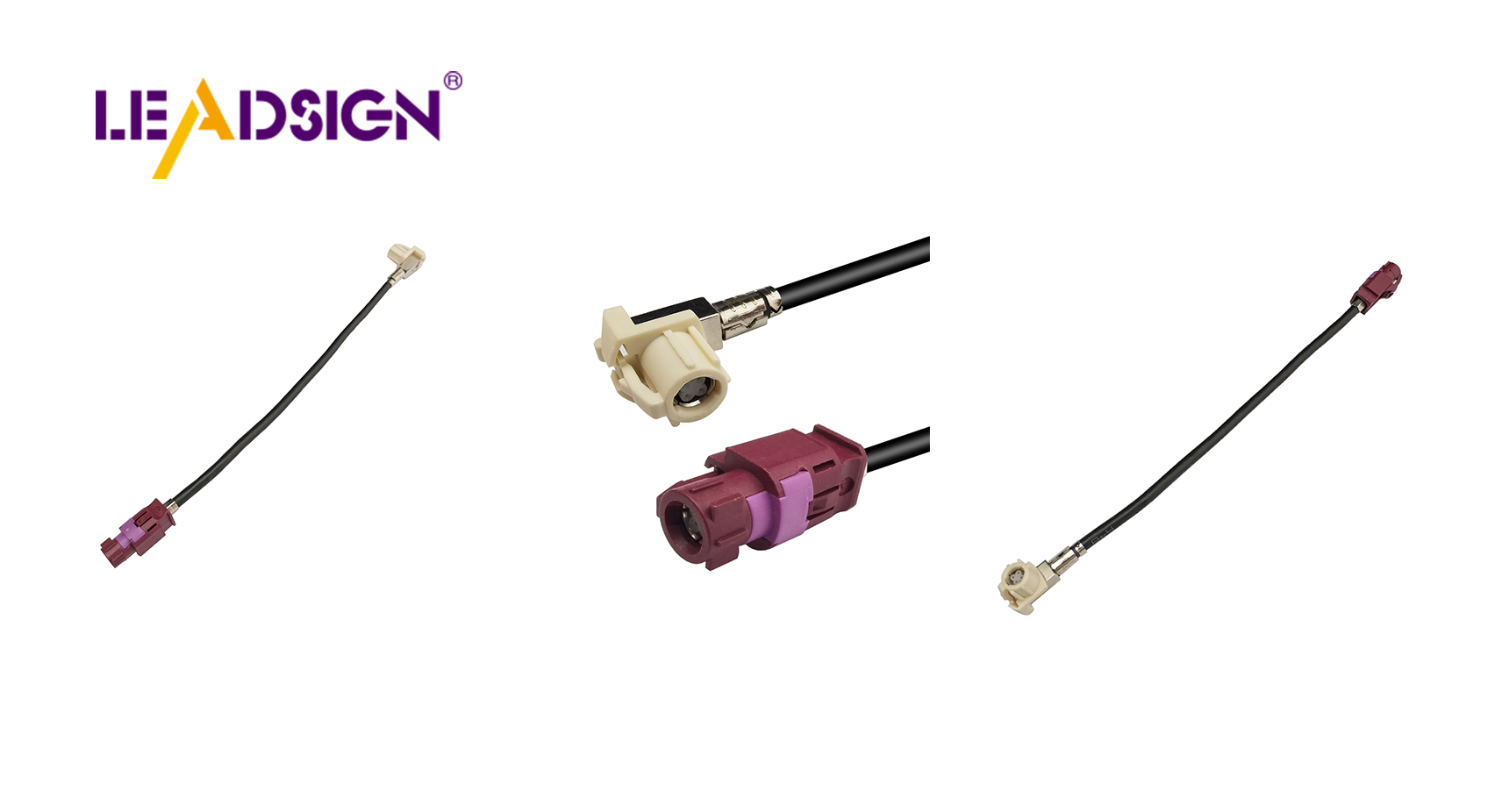

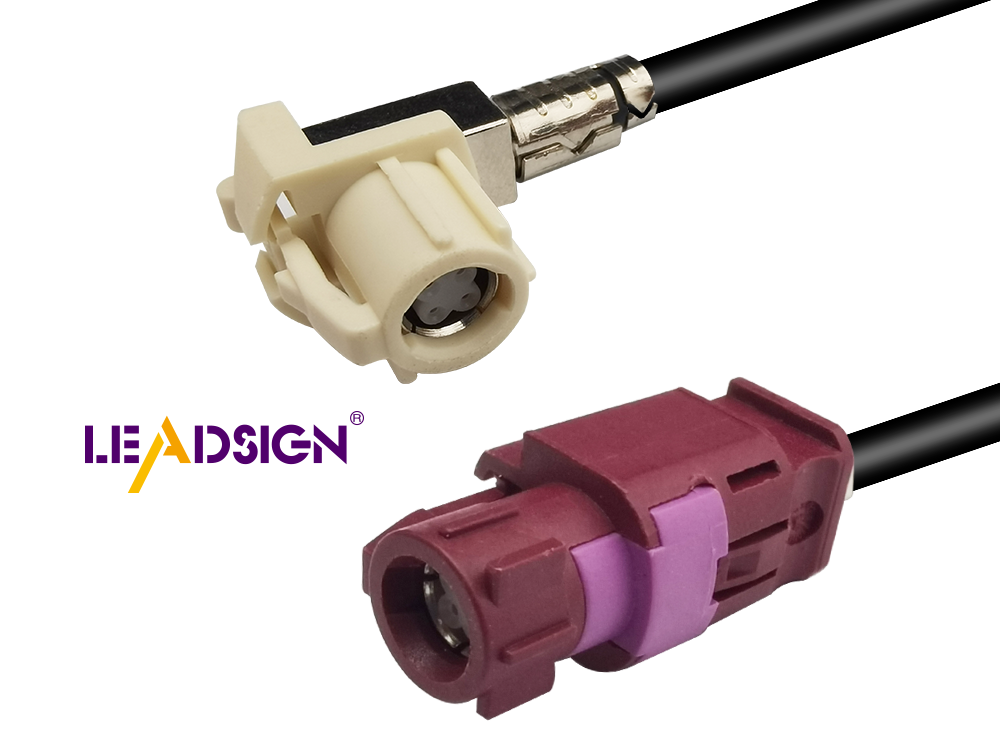

Significance of Fakra Auto Connectors in Contemporary Cars