Essential Automotive Electrical Connectors Types Explained

Car electrical connectors are important parts in vehicles. They help connect electrical systems smoothly. These automotive electrical connectors types affect how well a car works and stays safe. As cars change, more reliable connectors are needed. This is because of more electric and hybrid cars being used. The market for these connectors will grow big, reaching USD 8.76 billion by 2029. Knowing different types of car electrical connectors is key to keeping cars working well and safely.

Types of Car Electrical Connectors

Knowing different car electrical connectors is important. It helps keep cars working well and safe. Each type has a special job and offers unique help.

Inline Connectors

Uses and Benefits

Inline connectors join two wires in a straight line. They make sure signals pass without stopping. These connectors are easy to put on and take off. This makes them good for places where you need to unplug often. Their small size lets them fit in tight spots in the car.

Common Applications

Inline connectors are used in car lights, like headlights and taillights. They also connect sensors and switches to the main wiring system. They work well for power sharing and engine control systems too.

Chassis Connectors

Uses and Benefits

Chassis connectors, or panel connectors, attach to the car's body or panel. They give a strong spot for cables, making sure they stay steady. These connectors are key for strong links in car systems, especially where there’s movement.

Common Applications

Chassis connectors are used in powertrain parts like connecting the engine control unit (ECU) to wires. They're also found in safety systems like airbags and brakes, where stable links are very important.

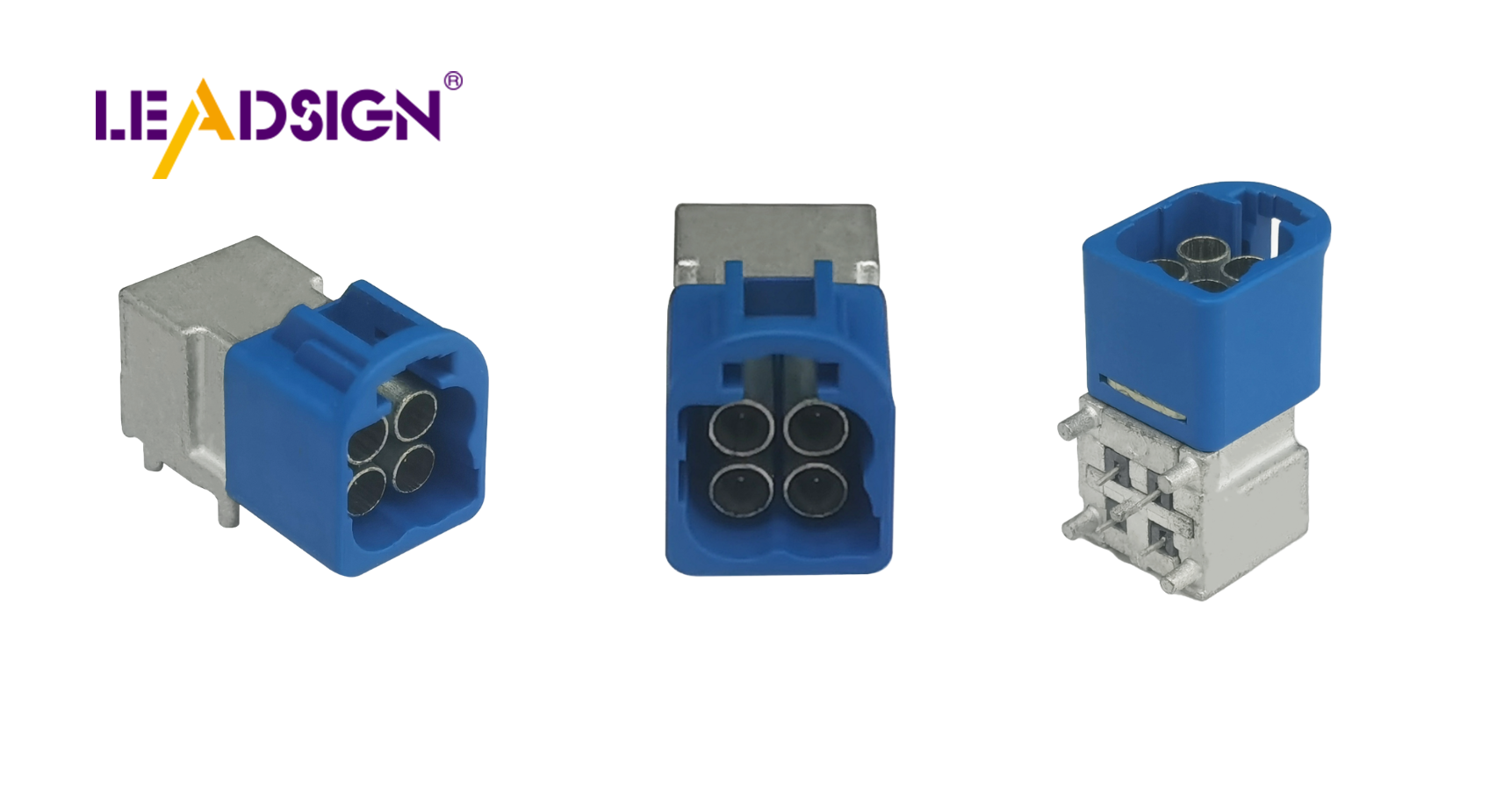

PCB Mount Connectors

Uses and Benefits

PCB mount connectors link electronic parts to circuit boards (PCBs). They offer a secure way to mix electronic systems in cars. These support many connections, allowing complex circuits in small spaces.

Common Applications

PCB mount connectors are common in entertainment systems, navigation units, and driver help techs. They allow smooth talk between electronic modules so GPS, audio, and video work right. They're also key in new cars' computer-controlled systems for best performance.

High-Speed FAKRA-Mini Connectors

Uses and Benefits

High-Speed FAKRA-Mini connectors are a big step forward. They handle fast signals, up to 20 GHz, and data rates of 28 Gbps. These connectors are key for new cars needing quick data moves. Their small size fits in tight car spaces, using space well. This makes them great where space is tight but high performance is needed.

The High-Speed FAKRA-Mini connectors have many good points:

Small Dimensions: They use 80% less space than old ones.

High Mechanical Robustness: They last long even in tough conditions.

Cost Optimization: Even with their features, they are affordable for makers.

Common Applications

These connectors work in many high-tech car systems. They help self-driving tech with fast data swaps for quick choices. Driver help systems need these for safe and smart driving. Also, they are important in navigation and entertainment systems, linking GPS, audio, and video smoothly. Back seat entertainment uses them too for better passenger fun.

Features of Car Electrical Connectors

Knowing car electrical connectors' features is key for safety and performance. These features show how well they work in cars.

Material

Materials Used

Different materials make car electrical connectors. Common ones are plastic, metal, and rubber. Plastic keeps water out and insulates. Metal helps electricity flow well. Rubber makes them bendy and seals better.

Effect on Performance

Material choice affects connector work. Metal helps electricity move with less loss. Plastic and rubber keep water and dust away. This keeps connectors working in tough places.

Sealing

Why Sealing Matters

Sealing is important for car electrical connectors. It stops dirt and water from getting in. Good sealing makes connectors last longer, even in hard spots.

Sealing Types

There are different ways to seal car connectors. Gaskets and O-rings fit tightly around them. Some use gel to keep water out. These ways help connectors stay strong over time.

Locking Mechanisms

Locking Types

Locking parts hold connectors together safely. Latch locks use clips to join them easily. Snap locks connect quickly without fuss. Threaded locks give a strong hold.

Secure Locking Benefits

Good locking stops unwanted disconnects. It keeps car systems steady and safe. This steadiness is crucial for keeping car electrical connections working well.

Why Good Connectors Matter

Good connectors are very important in cars. They help cars work well and safely. Knowing why good connectors matter shows how they help cars.

Lasting Strength

Long-lasting Use

Good connectors last a long time. They don't break easily. This strength keeps connections steady. Cars need these steady links to run right. Metal connectors are strong and reliable, even in tough places.

Fighting Weather Problems

Car connectors face weather issues like heat and wetness. Good ones handle these problems well. They keep systems safe from harm. This means cars can work in all kinds of weather.

Fitting Right

Perfect Fit Needed

Connectors must fit just right in cars. Good ones fit perfectly with car parts. This stops loose links and cuts down on failures. A perfect fit makes cars safer and more reliable.

Stopping Electrical Trouble

Bad connectors cause electrical trouble. Loose or wrong ones can make short circuits happen. They might also mess up systems. Good connectors stop these troubles by making sure connections are tight and safe.

Saving Money

Cost vs Quality Balance

Buying good connectors may cost more at first, but they save money later on. They lower repair costs and need fewer changes over time. Balancing cost with quality helps car owners save money.

Saving Over Time

Using good connectors saves money over time because they cut down on electrical problems, leading to fewer repairs or swaps needed later on, making them worth the initial spend.

Good connectors hold tight, handle tough weather, and share power well. As cars get smarter, we need better connectors too. Buying good ones makes cars run better and saves money over time. It also keeps them safe for longer.

See Also

Understanding HSD Connectors Used In Cars Today

Why Fakra Connectors Matter In Today's Vehicles

Significance of FAKRA Connectors In Car Technology