Emerging Trends in Automotive Networking and Vehicle Connectors

Vehicle connectors are very important in the connected car world. They help different systems communicate with each other smoothly. This enables exciting features like music systems, sensors, and safety tools. Innovations in vehicle connectors are rapidly advancing with the rise of electric and self-driving cars. Consumers are seeking faster, stronger, and more efficient connectors as vehicles evolve. Current trends indicate a demand for smaller designs and improved data sharing, aligning with the increasing sophistication of today’s cars.

Key Takeaways

Automotive connectors are essential for vehicle communication, enabling features like infotainment, safety systems, and electric vehicle charging.

The trend towards smaller and multifunctional connectors helps save space and weight in vehicles, improving efficiency and performance.

Fast data sharing through advanced connectors is crucial for smart and self-driving cars, ensuring real-time communication between systems.

Ruggedized connectors are designed to withstand harsh conditions, making them ideal for off-road and racing vehicles.

Innovations in materials, such as eco-friendly and recyclable options, are shaping the future of automotive connectors, promoting sustainability in the industry.

FAKRA connectors enhance vehicle connectivity by providing high-speed data transmission for applications like GPS and telematics.

Overview of Automotive Connectors and Their Applications

Automotive connectors are key parts in today’s vehicles. They help systems work together by sending power, signals, and data. These connectors are the base of vehicle wiring, making automotive electronic systems work well. Knowing their types and uses shows how they improve vehicle connectivity and performance.

Types of Automotive Connectors

Power Connectors

Power connectors move high currents and transfer energy efficiently. They are important for engines, lights, and electric motors. Their strong build handles heat and shaking, making them crucial in automotive applications.

Signal Connectors

Signal connectors send low-voltage signals between vehicle parts. They are vital for sensors, cameras, and infotainment systems. These connectors are detailed in design to meet different signal needs in vehicles.

Hybrid Connectors

Hybrid connectors mix power and signal functions in one unit. They simplify vehicle wiring and save space. By combining tasks, they make vehicles lighter and better, which helps electric and self-driving cars.

Applications of Vehicle Connectors

Internal Systems (e.g., Infotainment, Sensors, ADAS)

Vehicle connectors are needed for systems like infotainment, sensors, and ADAS. They provide steady links for fast data sharing. For instance, ADAS connectors help with safety tools like collision alerts and lane-keeping.

External Connectivity (e.g., Charging Ports, V2X Communication)

External systems use special connectors to link vehicles to outside systems. Electric car charging ports use high-power connectors for energy transfer. V2X connectors share data with roads, cars, and people for smarter travel.

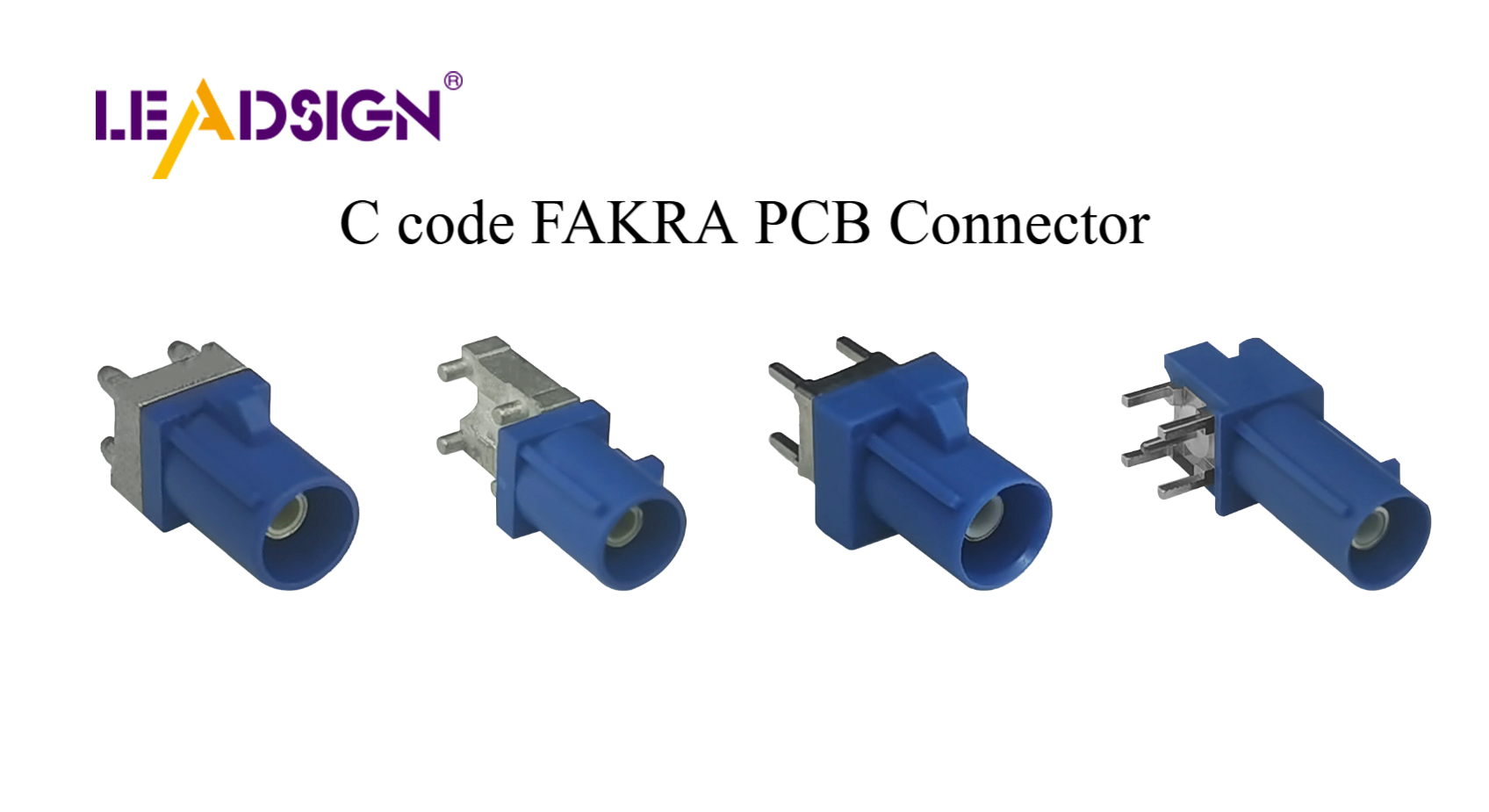

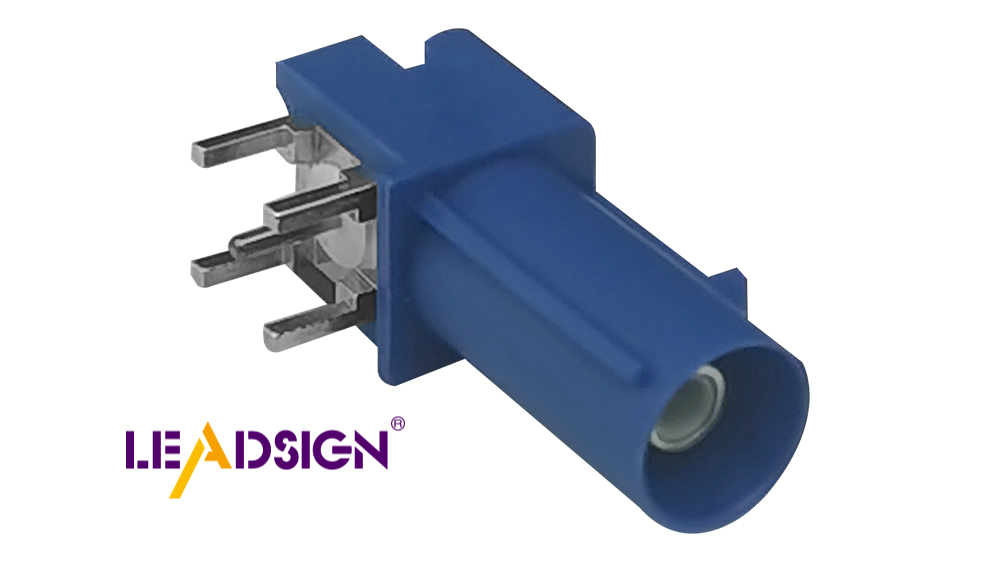

Specialized Connectors (e.g., FAKRA Connectors for RF Applications)

Special connectors like FAKRA connectors are made for specific jobs like RF tasks. They are used in GPS, telematics, and Bluetooth systems. Their strong design and coding ensure they work well. With fast data speeds and waterproof options, FAKRA connectors are key to advanced connectivity solutions.

Emerging Trends in Automotive Connector Technology

Automotive connectors are changing fast and improving vehicles. As cars get smarter, better connectors are needed. New ideas in connector technology help meet modern car needs.

Smaller and Compact Connectors

Why smaller connectors are helpful

Smaller connectors save space in cars. This lets makers add more features without adding weight. They also help cars use less fuel and work better. Electric and self-driving cars benefit most since space is very important.

Problems with making connectors smaller

Making connectors smaller can be tricky. They still need to work fast and send signals clearly. Engineers use strong materials like special plastics to solve these problems. These materials help small connectors handle power and data well.

Fast Data Sharing

How connectors help with Ethernet, 5G, and fast data

Fast connectors are key for today’s cars. They help systems talk to each other using Ethernet and 5G. These connectors move data quickly and reliably. This is important for cars that need real-time info from sensors and cameras.

Why fast data is needed for smart cars

Smart cars need fast data sharing to work right. They use connectors to handle lots of data from safety tools like ADAS. These connectors make sure systems work smoothly and safely. Without them, self-driving cars wouldn’t be possible.

Strong and Tough Connectors

Connectors that handle tough weather and shaking

Some connectors are made to survive bad weather and shaking. They keep working even in rain, dust, or bumpy roads. These tough connectors are great for off-road and racing cars.

Use in off-road and racing cars

In rough conditions, strong connectors are a must. Off-road and racing cars need connectors that can handle stress and speed. These designs make sure connectors stay reliable no matter what.

Multifunctional Connectors

Combining power, data, and signals in one connector

Multifunction connectors change how car systems work together. These connectors send power, data, and signals through one connection. This makes car designs simpler and more efficient.

Before, cars used separate connectors for each task. This created messy wiring that took up space and added weight. Multifunction connectors fix this by doing many jobs at once. For example, some connectors send many signals through one link. They keep communication steady, even in tough conditions.

New connector technology focuses on being strong and reliable. Multifunction connectors use special materials like strong plastics. These materials last long, resist rust, and work well. They also send data fast and deliver power efficiently. This makes them perfect for electric and self-driving cars.

Making cars lighter and simpler

Multifunction connectors help make car designs less complicated. They combine many functions into one small piece. This removes the need for heavy wiring systems. Lighter cars use less energy and go farther on a charge.

These connectors also make building cars easier. With fewer parts, production is quicker and cheaper. They also make cars more reliable by reducing weak spots. Their tough design works well in heat, cold, or bumpy roads.

For drivers, multifunction connectors mean better cars with cool features. They help systems like music, sensors, and safety tools work together. Whether it’s an electric car or a self-driving one, these connectors make driving safer and smoother.

New Ideas in Car Networking and Electric Vehicle Tech

The car industry is changing fast with new tech. Better vehicle connections and electric car tools are leading this change. Connectors are key to making these ideas work. They help cars stay connected and improve how they run and keep us safe. Let’s see how these changes are shaping the future of cars.

Better Ways for Cars to Communicate

Using Ethernet for faster car networks

Ethernet is now a big part of car connections. It helps systems share data quickly, which is needed for real-time tasks. Think of it as the main link for systems like cameras and sensors. Unlike old wiring, Ethernet is simpler and lighter. This makes cars work better and use less energy. New connector designs match this trend by being light and fast.

Mixing CAN, LIN, and FlexRay systems

Besides Ethernet, systems like CAN, LIN, and FlexRay are also important. They help car parts, from sensors to safety tools, work together well. Special connectors for these systems keep data flowing smoothly and safely. This setup makes sure cars work right in all kinds of conditions.

Connectors for Smart and Self-Driving Cars

Helping sensors work together fast

Smart car systems need sensors to share data quickly. Connectors send this data from cameras and radar to the car’s computer. This must happen fast for self-driving cars to make safe choices. High-speed connectors make sure there’s no delay in this process.

Keeping safety systems connected

Safety tools like crash alerts need strong connections. Sealed connectors are made to handle tough weather and dirt. They keep working in heat, rain, or dust. These connectors make sure safety tools stay reliable for a long time.

Connectors for Electric and Hybrid Cars

Special connectors for car batteries

Electric cars need connectors that can handle high power. These connectors move energy between the battery and other parts. They are made to resist heat and last long. Their design also keeps them safe from electrical problems.

Fast-charging connectors for electric cars

Fast-charging has made electric cars easier to use. These connectors let cars charge quickly, saving time. This makes more people want to drive electric cars. They also work with different charging setups, making them easy to use everywhere.

FAKRA Connectors and RF Applications

Use in GPS, Telematics, and Infotainment Systems

FAKRA connectors are important for modern cars. They help with high-frequency tasks like GPS, telematics, and infotainment. For example, when your GPS gives directions or music plays smoothly, FAKRA connectors keep the data steady and clear.

These connectors handle radio frequency (RF) signals. They link antennas to devices for things like navigation and tracking. In telematics, they help cars share data with outside systems. This improves how cars connect and work. Their strong design ensures they work well, even in tough conditions.

Benefits Such as Secure Coding, Durability, and High Data Rates

FAKRA connectors have many benefits for car systems. One is their secure coding. This makes sure each connector fits only where it should. It prevents mistakes and keeps systems reliable.

They are also very durable. FAKRA connectors can handle heat, cold, shaking, and rain. Even on rough roads, they keep working. Their tough build means they last a long time without needing replacement.

FAKRA connectors also send data very fast, up to 8 Gbps. This speed is great for advanced systems like infotainment and telematics. Fast data sharing makes driving smoother and more connected.

These connectors come in different designs, like waterproof ones. This helps car makers design better layouts. As car tech improves, FAKRA connectors meet the need for strong and fast connections.

Challenges in Automotive Connector Technology

As cars get smarter, automotive connector technology faces new problems. Engineers must make sure connectors meet modern automotive applications needs. These problems include handling heat, fixing supply chain delays, and using eco-friendly materials.

Thermal Management

Solving Heat Problems in High-Power Connectors

High-power connectors can get very hot when used. This heat can lower how well they work. To fix this, engineers create connectors that cool down easily. They use materials that move heat away from important parts. Good heat control helps connectors work well in electric cars and charging systems.

Better Materials and Designs for Heat Control

The materials used in connectors are important for heat control. Special plastics and metals that handle heat well are now common. These materials stop overheating and make connectors last longer. New designs, like vents or cooling systems, also help with airflow. These ideas keep connectors working in tough places, like in advanced driver assistance systems.

Supply Chain and Manufacturing Problems

How Supply Chain Delays Affect Connectors

Global supply chain problems have made it harder to get connectors. Delays in getting materials and slower production have caused issues. This means making cars or fixing them might take longer and cost more.

Fixing Supply Chain and Quality Problems

To solve these problems, companies are finding local material suppliers. They are also using machines to make connectors faster and better. For example, Hirose Electric Co., Ltd. makes strong connectors like the HR41 Series. These connectors help with vehicle wiring and connectivity solutions. These steps ensure you get reliable products even with supply chain issues.

Lightweight and Eco-Friendly Materials

Making Cars Lighter for Better Fuel Use

Using lighter materials in connectors helps cars use less fuel. Lighter vehicle wiring and parts mean cars need less energy. This is very helpful for electric and hybrid cars. Lighter connectors also let makers add more features without making cars heavier.

Using Recyclable and Green Materials in Connectors

Eco-friendly materials are now a focus in the automotive connector market analysis. Companies are using recyclable materials to make connectors. These materials are better for the planet and support green tech goals. For example, biodegradable plastic connectors are strong and eco-friendly. This change helps the environment and improves connectivity solutions for the future.

Car connectors are changing how vehicles work. They make cars smarter, safer, and better. New ideas like smaller designs and faster data sharing are important. These changes help electric and self-driving cars work well. Connectors also allow quick charging and eco-friendly solutions. As these needs grow, connectors will stay important for progress. With these technologies, cars will be more connected, efficient, and green in the future.

FAQ

What are automotive connectors, and why are they important?

Automotive connectors link parts of a car together. They move power, data, and signals between systems. This helps features like music, sensors, and safety tools work. Without them, these systems wouldn’t function. They are especially important for electric and self-driving cars.

How do FAKRA connectors enhance vehicle connectivity?

FAKRA connectors are used for tasks like GPS and music systems. They have a special design to prevent wrong connections. They send data very fast, up to 8 Gbps. Their strong build makes them last long, even in tough conditions.

What trends are shaping the future of automotive connectors?

Future connectors will be smaller, faster, and do more jobs. Lightweight and recyclable materials are now common to help the planet. Sealed designs make them strong for electric and smart cars.

How do connectors support electric vehicles (EVs)?

Connectors in EVs move power from batteries to other parts. They allow quick charging, saving time for drivers. Their tough design keeps them safe and efficient, even under stress.

Why is miniaturization important in automotive connectors?

Smaller connectors save space and reduce car weight. This lets makers add more features without hurting performance. They also improve fuel use and battery life, helping electric cars.

What materials are used in modern automotive connectors?

Modern connectors use strong plastics and recyclable materials. These materials handle heat and last long. Some are biodegradable, which helps protect the environment.

How do ruggedized connectors benefit off-road and racing vehicles?

Rugged connectors work well in tough places like dirt and rain. They stay reliable even with shaking or bad weather. This makes them great for off-road and racing cars.

What role do connectors play in Advanced Driver Assistance Systems (ADAS)?

Connectors in ADAS help sensors and cameras share data fast. They make safety tools like crash alerts and lane-keeping work well. Reliable connectors are key for these systems to function.

How are automotive connectors becoming more eco-friendly?

Companies now use recyclable and biodegradable materials for connectors. They also avoid harmful substances and use energy-saving methods. These steps make cars greener and better for the planet.

Can automotive connectors handle high-speed data transmission?

Yes, modern connectors send data quickly for systems like 5G. They help car parts communicate fast and reliably. This is important for features like music systems and safety tools.

See Also

Enhancing Automotive Data Flow With Superior Connectors And Cables

Transforming Vehicle Connectivity Through The Benefits of HFM Connectors

Boosting Data Transfer: Why High-Speed Connectors Matter in Vehicles