Emerging Trends in Automotive Wiring Connector Types

Wiring connectors are very important in today's cars. They help different electronic parts communicate with each other easily. As technology advances, understanding the various automotive electrical connectors types and new connector trends is key. The car industry evolves rapidly, introducing new types of electrical connectors to meet growing demands. For example, a study showed that 25% of public EV chargers didn't work due to failures. This highlights the necessity for reliable connectors. Being aware of these trends helps create cars that are efficient, environmentally friendly, and safe.

Current Challenges in Car Wiring

Environmental Rules

New rules on pollution have changed car connector materials. The RoHS Rules and the EU Directive 2011/65/EU, also called RoHS 2, limit harmful stuff in electronics. These rules make companies find new materials that are eco-friendly. So, the industry must create connectors that can be recycled and reused. Companies need to invent connectors that follow the rules but still work well.

Advanced Driver Help Systems (ADAS)

Adding Advanced Driver Help Systems (ADAS) makes car wiring more complex. ADAS tools like lane help and cruise control need many sensors and cameras. This needs strong connectors for good communication between parts. Makers must design connectors that handle more data and work well in different situations.

Fun Systems

Today's cars have cool fun systems needing fast data movement. People want better sound, video, and maps, so data needs grow. Connectors should move data quickly to meet these demands. Making connectors that manage lots of data is key for keeping these systems working well.

Electric Cars (EVs)

Electric cars have special wiring challenges. They need to handle high-voltage connections. These cars use complex systems to power motors and other parts. High-voltage connectors carry big electric loads safely and efficiently. Makers design these connectors for tough jobs, ensuring they work well in different conditions.

Handling high-voltage connections in EVs needs careful planning. Connectors must move lots of electricity without getting too hot or breaking. Engineers make connectors that manage high voltages with little energy loss. They use new materials and designs for this balance. Connectors also need to resist things like water, dust, and temperature changes.

Handling high-voltage in EVs needs careful planning. Connectors must move lots of electricity without getting too hot or breaking. Engineers make connectors that manage high voltages with little energy loss. They use new materials and designs for this balance. Connectors also need to resist things like water, dust, and temperature changes.

Safety and Strength in EV Connectors

Safety and strength are key for EV connectors. They must stop dangers like short circuits or fires that can harm people inside the car. To keep them safe, makers test them a lot. They check if connectors can handle stress and bad weather. Strong connectors last long, cutting down on repairs and making EVs more reliable.

New Ideas in Connector Technology

Smaller and Lighter Design

Car connectors have changed a lot. They are now smaller and lighter. These tiny connectors help make cars weigh less. Lighter cars use less fuel and go faster. Engineers use new materials to make these small designs. This helps fit more gadgets in cars without losing power.

Better Connections and Data Movement

People want faster data in their cars. This need has led to new car connectors. These can send data quickly, which is important for cool car systems like music players and smart driving aids (ADAS). Smart connectors can check themselves and tell if something is wrong before it gets bad.

Stronger and More Reliable

Strongness is key for car connectors. New materials stop rust, making them last longer even in tough places. Engineers work on designs that stay strong in heat or wet conditions. This means fewer fixes are needed, keeping the car running well.

Example Study: EV Connector Problems and Fixes

EV charging connectors sometimes don't match up.

Makers have made different EV charging connectors.

These changes help fix problems EV drivers face with connectors.

By solving these issues, makers keep improving car connectors, so they work better for today's cars. Knowing about these changes helps keep cars safe, fast, and green as they get better over time.

Future Trends in Connector Types

Linking with Smart Cars and IoT

Connectors are key for cars talking to everything around them. They help cars connect with the world, making driving safer. As smart cars grow, connectors need to support self-driving tech. These connectors let sensors, cameras, and controls share data fast. This keeps self-driving systems working well. New high-speed connectors like the Minimize Micro Coaxle High-Speed Connector show progress here. This connector is 30-50% smaller and lighter, fitting tiny car parts.

Going Green

Car makers care more about being green now. They use eco-friendly materials for connectors. Companies try biodegradable and recyclable choices to cut waste. This helps the planet and follows rules too. Using green stuff shows they want to protect nature.

Custom Fit and Flexibility

More people want special connectors for their car models. Custom designs meet different needs in looks and workability. Modular designs allow easy swaps and fit many setups. This helps with different car builds from small cars to big trucks.

Knowing new trends in car wiring connectors is important. These changes make cars work better, safer, and greener. For example, the new connector design is 30-50% smaller and lighter. This meets the need for tiny and light parts. These ideas save space and fit well in cars. People in the car industry should learn and adjust to these updates. By doing this, they help make future cars that are good for the earth and safe to drive.

See Also

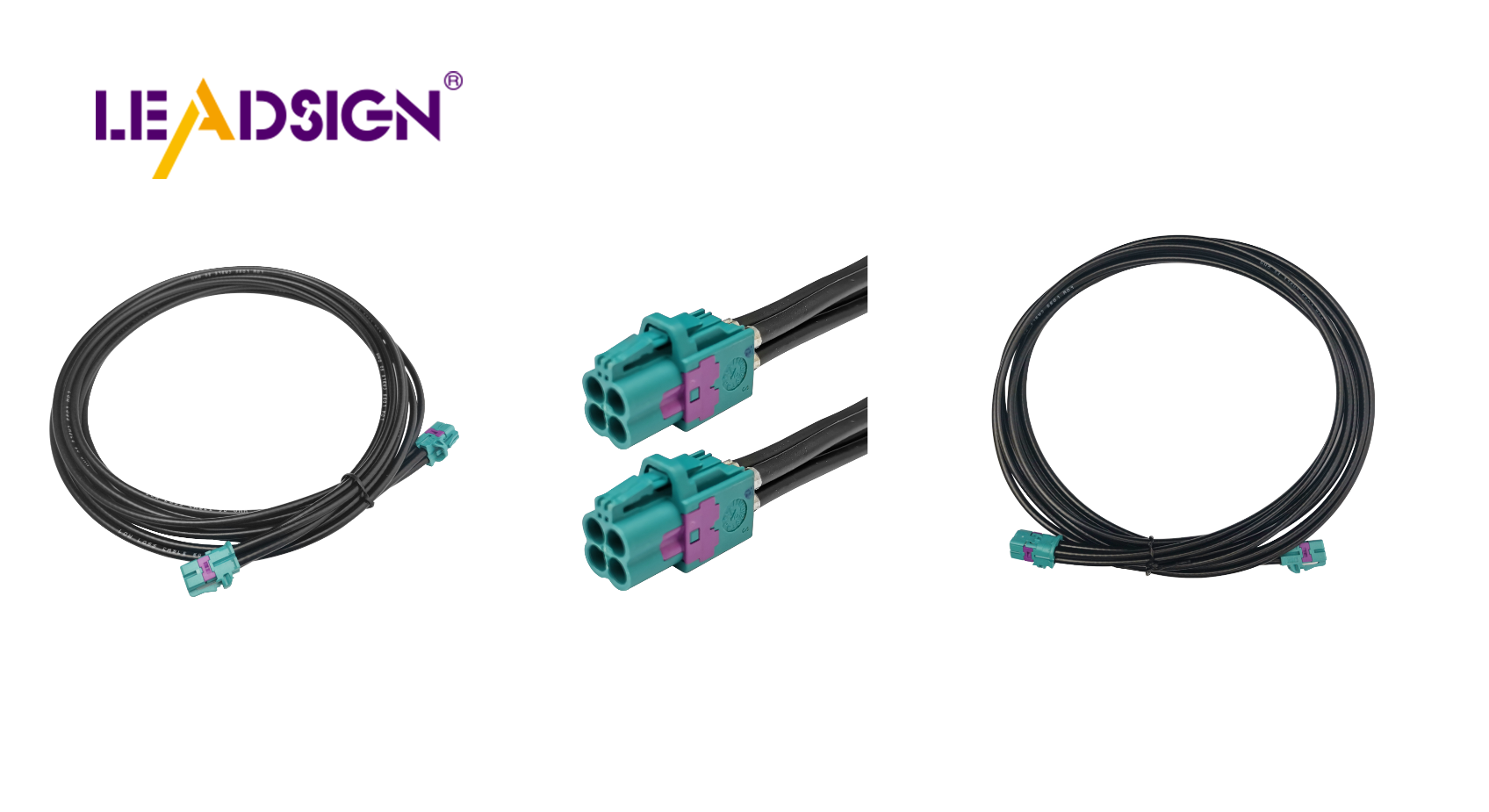

Understanding HSD Connectors Essential for Automotive Applications

Fakra Connectors: Crucial Components in Today's Vehicles

Fakra Connectors: Key Elements in Automotive Technology