Emerging Trends in Automotive Wiring Connector Types

New trends in automotive electrical connectors types are changing the industry. These trends solve problems like space, weight, and strict regulations. They also facilitate the use of new technologies. Modular connectors assist with automation as labor costs rise and the workforce diminishes. The electric vehicle market is projected to grow significantly, from USD 255.54 billion in 2023 to over USD 2,108.80 billion by 2033. Keeping up with these trends is crucial for industry professionals to stay ahead and ensure vehicles remain safe and functional.

Driving Factors Behind Emerging Trends

Technological Advancements

Impact of Electric Vehicles (EVs) on Connector Design

Electric cars are changing how connectors are made. As more people use electric cars, we need connectors that can handle lots of power safely. These connectors must be small and light to fit in the car. Companies work hard to make sure these connectors do their job well.

Role of Advanced Driver Assistance Systems (ADAS)

ADAS helps make cars safer and easier to drive. It uses tools like cameras and radar to see around the car. This tech makes electric cars more popular and safe. Scientists try to make ADAS use less energy so it doesn't drain the car's battery too fast. As ADAS becomes common, special connectors are needed for these systems.

Regulatory Requirements

Environmental Regulations and Their Influence

Rules about the environment change how car parts are made. Governments want less pollution, so they push for green tech in cars like hybrids and electrics. Companies must create parts that follow these rules, making sure cars are eco-friendly.

Safety Standards and Compliance

Safety rules keep cars safe for everyone. These rules help protect people and improve how cars work. Connectors have to be strong and reliable in all weather conditions. Companies focus on making connectors that meet safety rules, ensuring vehicles stay safe.

Decline of Traditional Connectors

Limits of Old Connectors

Space and Weight Problems

Old connectors have trouble with space and weight. Cars today need small and light parts. Old connectors are big and don't fit well in new cars. They take up too much room, making it hard for engineers to design freely. The extra weight from these connectors can make cars less efficient. So, car makers look for better options that fit today's smaller car designs.

Strength and Trust Issues

Old connectors aren't very strong or reliable. They often break in tough conditions like heat or shaking. This can cause electrical problems, making cars unsafe or not work well. Car makers want connectors that last without needing many replacements. The need for stronger solutions pushes the move to new connector types.

Move to New Options

Good Things About New Connectors

New connector types have many benefits over old ones. They are stronger and more reliable, working well in different situations. These connectors also send data fast, important for high-tech car systems. Their small size helps cut down car weight, saving fuel. Plus, modular connectors help with automation during production, which is important as labor costs rise.

Stories of Successful Changes

Switching to Electric Fleets: Companies in the UK have moved to electric fleets using modern connectors successfully. These changes show why using new tech is key for better efficiency and being eco-friendly. By following these examples, other companies can switch to electric cars more easily.

Modular Connectors Help Automation Grow: Using modular connectors has boosted automation in factories. These connectors give more flexibility and efficiency needed for today's manufacturing methods. As automation becomes vital due to higher labor costs, switching to modular connectors helps manufacturers stay ahead.

New Connector Types Are Growing

Cars are changing fast. New connectors help them change. These connectors make sure cars work well by sharing power and information.

Fast Data Connectors

Fast data connectors are important now. They help with new car entertainment systems and staying connected.

Use in Entertainment Systems

Car entertainment systems do many things, like maps and music. Fast data connectors help them work by moving data quickly. They let you hear and see high-quality sound and pictures. As cars connect more, we need good connectors for lots of data.

Working with Car Networks

Car networks use fast data connectors to talk between parts. These connectors join systems like maps, music, and safety into one network. This makes the car work better. Car makers want these connectors because people want smart cars.

Small and Light Connectors

As cars get smaller, we need small and light connectors. They save space but still work well.

Fixing Tight Spaces

Small connectors fit in tight spaces in cars. Engineers can design smaller systems that still work great. These connectors make cars lighter, saving fuel. By using space well, they add more features to the car.

Examples in Today's Cars

Today's cars show small and light connector use. Electric cars use them for battery wires and power sharing. Self-driving cars use them to link sensors and controls. These examples show why new connector types are needed as tech grows.

Uses in Modern Systems

Connectors in ADAS

ADAS is very important for today's cars. It makes driving safer and better. Logic Fruit Technologies knows a lot about car tech. They say ADAS is key for electric cars.

"Adding Advanced Driver Assistance System (ADAS) tech to these cars is crucial. It makes them more popular and ensures safe electric driving as EVs become more common."

Improving Sensor Links

ADAS needs sensors to work well. Sensors find obstacles, watch lanes, and help park. Connectors let sensors talk to the car's main system easily. Good connectors keep connections strong, even when it's tough outside. This strength helps the car react right away.

Keeping System Trustworthy

Trust in ADAS is a must-have. Connectors handle shaking, heat changes, and wetness. They make sure systems work in all conditions. Makers build connectors that pass strict safety checks. This ensures ADAS works well, giving drivers trust and calm.

Connectors in Fun Systems

Fun systems change how we drive now. They give maps, music, and connect features. These need strong connectors to work right.

Helping with Great Sound and Video

Great sound and video are part of new fun systems. Connectors help send clear sound and pictures fast. They make sure people enjoy movies or songs on the go.

Making User Experience Smooth

A smooth user experience matters in fun systems too. Connectors join screens, speakers, and controls together well. This lets users switch tasks easily without problems.

The car industry is seeing big changes in wiring connectors. New tech and rules are causing these shifts. Modular connectors are becoming popular. They help with automation and flexibility, unlike old connectors. Future ideas might make connectors even smaller and faster for new car tech. People working in this field need to know about these changes to stay ahead. They must ensure cars stay safe and work well. By accepting these updates, they can handle the changing world of car technology better.

See Also

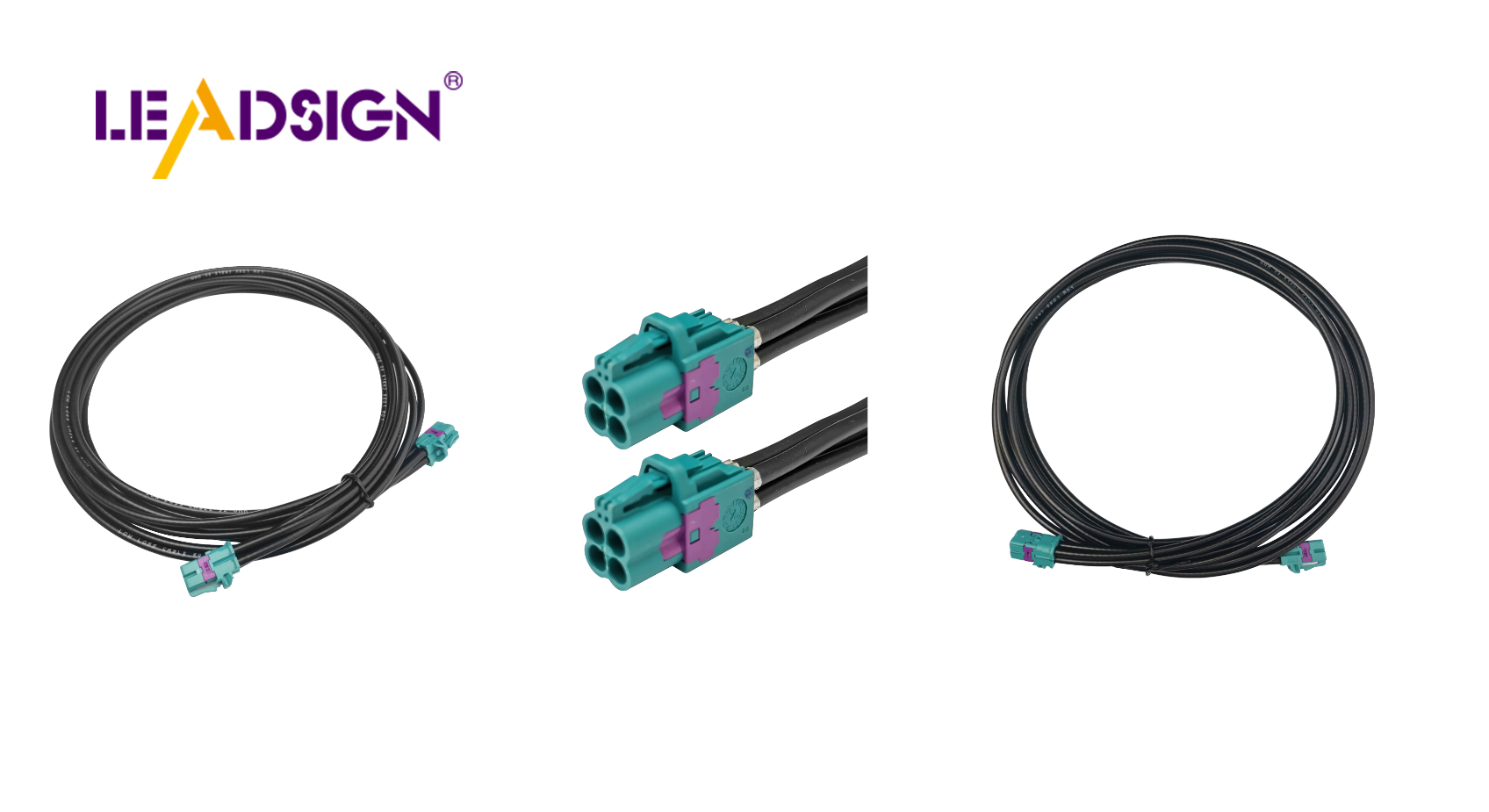

Understanding HSD Connectors' Role in Automotive Systems

Why Fakra Connectors Matter for Today's Vehicles

Significance of Fakra Connectors in Auto Manufacturing