Emerging Trends in Automotive Wiring Connector Types

Automotive electrical connectors types play a crucial role in vehicles, facilitating communication and power distribution among components. These connectors significantly impact vehicle performance and safety by maintaining robust connections, even under challenging conditions. The evolution of electric and hybrid vehicles is rapidly transforming the types of connectors used. The market for these automotive electrical connectors is projected to grow substantially, with an annual increase of 8% from 2024 to 2032. This underscores the importance of staying informed about emerging trends in connector technology.

Overview of Automotive Wiring Connectors

Definition and Functionality

Wiring connectors are key parts in cars. They help send electrical signals and power between different car parts. These connectors make sure all electronic parts work well together. This helps the car run safely and smoothly. By keeping connections strong, they stop problems that could cause safety issues or make the car less efficient.

Types of Wiring Connectors

FAKRA Connectors

FAKRA connectors are very important for high-frequency tasks in cars. They keep antennas connected, which are needed for GPS and radio. These connectors can handle tough conditions in cars, so they work well over time.

HFM Connectors

High-Speed Mini-FAKRA (HFM) connectors are a big step forward in connector tech. They are up to 80% smaller than regular FAKRA ones. These small connectors send data fast, up to 28 Gb/s. Their small size and strong build suit new car tech like self-driving systems and infotainment. HFM connectors come straight or at an angle, offering flexibility and less weight, making cars more efficient.

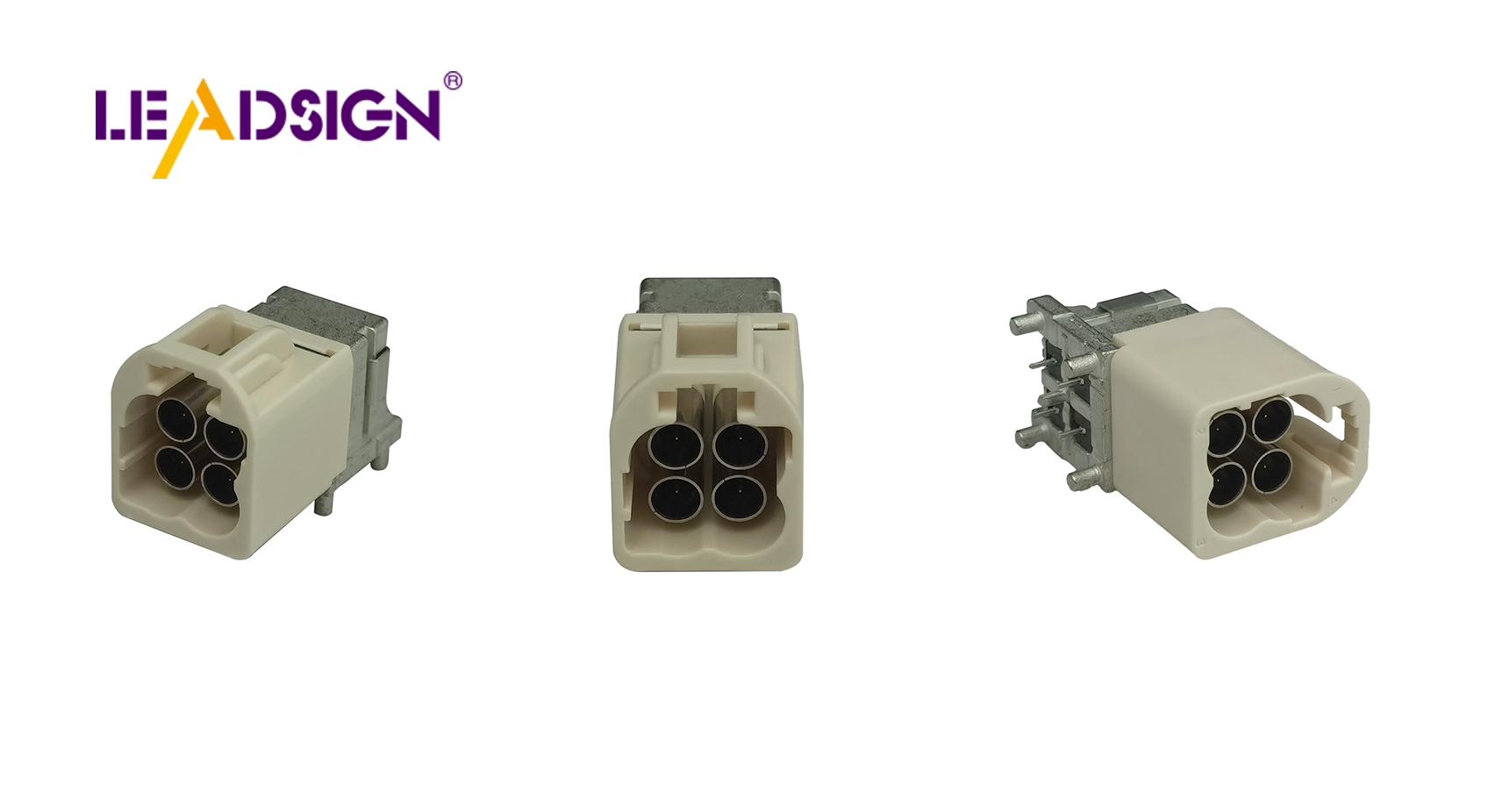

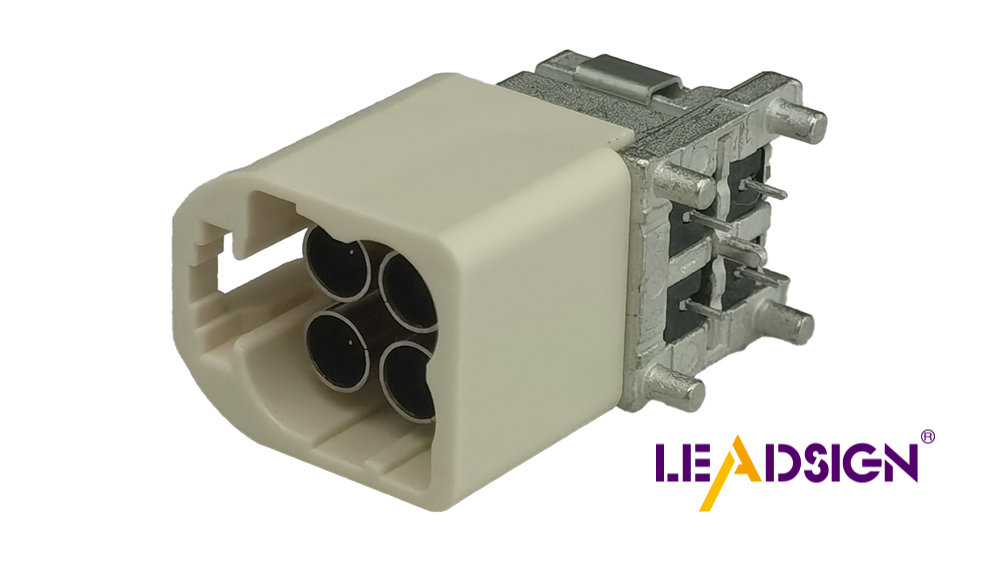

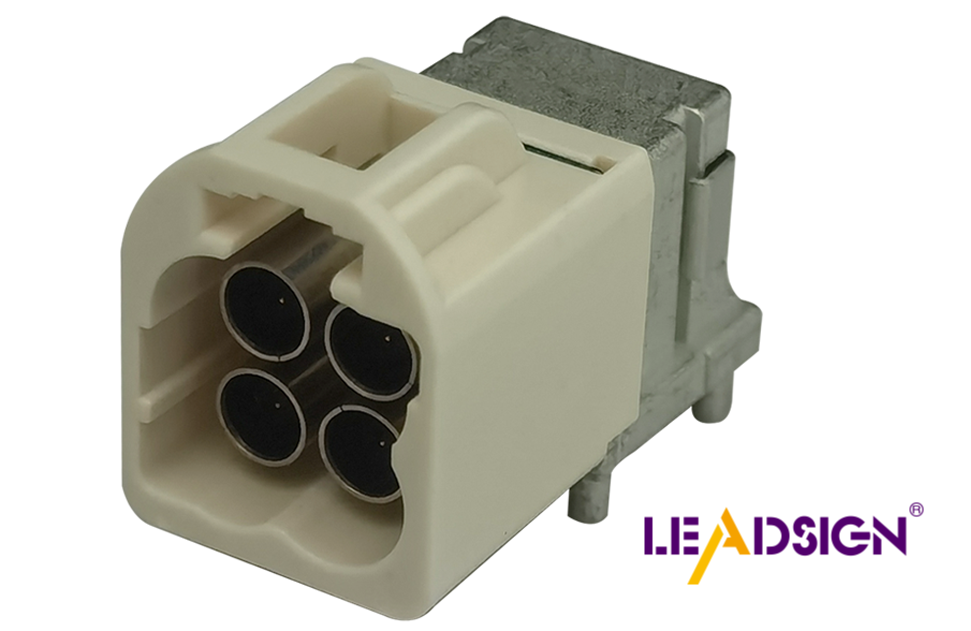

High-Voltage Connectors

High-voltage connectors are crucial for electric cars today. They meet the big power needs of electric engines by moving energy from battery to motor efficiently. These connectors handle high currents and voltages, which is vital for safe electric car use.

Current Trends in Connector Technology

Miniaturization

Making connectors smaller is changing the car industry. Tiny connectors have many benefits. They take up less space, weigh less, and make cars run better. These small parts fit into tight spots, letting more gadgets fit in cars. This is important as cars get more techy.

But making things smaller isn't easy. Engineers need to keep these tiny connectors working well. Smaller size can make them hard to handle and put together. Makers must find new ways to fix these problems so small connectors work great in today's cars.

Increased Durability and Reliability

Connectors need to be tough and reliable for cars. They must survive heat, shaking, wetness, and chemicals. Companies use strong materials and smart designs to make them last longer. Scientific Research Findings show using materials that fight off damage is key.

Testing is important for reliability. Tests check if connectors can handle being plugged in and out a lot. These tests guess how they will work over time in tough spots. By following strict test rules, companies ensure their connectors are strong and dependable.

Integration with Smart Technologies

Smart tech in cars changes connector needs too. Connectors now help with cool systems like self-driving and entertainment screens. They must send data fast for quick talks between car parts.

The Internet of Things (IoT) affects connector design a lot. IoT needs connectors that link easily and share data smoothly. As cars connect more, the need for smart-tech-ready connectors grows too. Makers must change with these trends, creating parts that fit modern car needs.

Future Predictions for Connector Development

Advancements in Materials

Use of Advanced Composites

Car connectors will use new materials soon. Makers will use strong composites to make connectors better. These materials are tough and last long. They help connectors survive rough car conditions. Using these, makers want connectors to last longer. This means fewer fixes and changes.

Environmental Considerations

Eco-friendly ideas matter for new car connectors. Car companies want to be green, so they pick safe materials. These materials cut down on pollution and can be recycled later. This change shows cars care about the earth more now.

Evolution of Industry Standards

New Standards for Safety and Efficiency

New rules will make car connectors safer and better. They will have locks to stop unplugging by mistake. Connectors must also work faster without losing power or data speed. Following these rules makes products safe and reliable.

Global Harmonization of Standards

Worldwide rules for car parts will grow important as cars spread everywhere. Companies aim for one set of rules globally, making trade easier. This helps all parts meet the same safety checks worldwide, making building cars simpler.

Impact of Electric and Autonomous Vehicles

Specific Requirements for Electric Vehicles

Electric cars need special connectors that handle big power safely. Makers focus on moving energy from battery to motor well, keeping things safe and working right.

Connector Needs for Autonomous Systems

Self-driving cars need smart connectors for their gadgets like cameras and sensors. Fast data sharing is key so the car can think quickly and drive itself safely.

Knowing the newest trends in car wiring connectors is key for workers. Electric and hybrid cars are changing fast. They need new connector ideas. These changes focus on making connectors smaller, lighter, and tougher. As things change, makers must keep up to stay ahead.

"Top companies spend a lot on research to grow their products," showing how important new ideas are here.

Workers should use these new technologies to meet what the industry wants now.

See Also

Essential Guide to HSD Connectors in Auto Sector

Significance of Fakra Auto Connectors in Modern Cars

Key Role of Fakra Connectors in Auto Sector