Emerging Trends in Automotive Wiring Connector Types

Automotive wire connectors play a crucial role in vehicles by facilitating communication between various car components. Over the years, the types of wire connectors automotive have evolved significantly, driven by the increasing demand for electric vehicles and advanced smart car systems. The market for automotive connectors is projected to expand from USD 7.01 billion in 2024 to USD 8.76 billion by 2029. Understanding the emerging trends in wire connectors is essential for manufacturers to meet the growing demand for safer and more efficient vehicles today.

Current Trends in Automotive Wiring Connectors

Miniaturization

Making connectors smaller is becoming popular. Tiny connectors have many good points:

Space Efficiency: They take up less room, helping cars be smaller.

Weight Reduction: Lighter connectors make cars weigh less, saving fuel.

But making these tiny connectors is hard:

Precision Manufacturing: Making them needs special skills and tools.

Maintaining Performance: Small connectors must still work well and send signals right.

Increased Durability

Connectors in cars need to be tough. Makers use strong stuff to make them last:

Advanced Materials: New metals like aluminum are used instead of copper.

Environmental Resistance: Strong materials help them survive bad weather.

Testing helps make sure they are strong:

Rigorous Testing: They are tested a lot to be safe and work well.

Quality Assurance: Strict checks keep them reliable.

Enhanced Connectivity

Cars need better connections, so new ideas are coming up for connectors:

Integration with Smart Systems: Connectors now link with smart parts for easy talk between car parts.

Impact on Vehicle Performance: Better links help cars work faster and talk quickly.

Makers create new things for electric and self-driving cars, focusing on better links and safety. This keeps new cars good and trustworthy.

Technological Advancements

Wireless Connectors

Wireless connectors are a big step in car tech. They have many benefits over old connectors:

More Movement: Wireless ones don't need to plug in, so parts can move more. This helps when space is tight or parts need to shift.

Better Safety: No physical link means less wear and tear. This makes the car's electric systems safer and more reliable.

In today's cars, wireless connectors are used in different places:

Electric Cars: As these cars grow, wireless connectors help systems talk easily.

Smart Systems: They work with smart systems like music and maps without wires getting in the way.

Fast Data Sharing

Fast data sharing is key for new cars. It lets systems swap info quickly, needed for self-driving and driver help features.

Why It's Important: Fast data helps cars act fast, boosting performance and safety. It links complex systems that need quick info swaps.

Tech for Fast Sharing: Some techs make fast data sharing possible in cars:

Fiber Optics: These cables send lots of data fast with little trouble.

Advanced Coaxial Cables: Made for high-speed signals, good for quick data moves.

With these tech advances, the car world keeps growing smarter, safer, and better at moving us around.

Types of Wire Connectors Automotive

Overview of Types

Automotive connectors are important parts in cars. They help different electronic systems talk to each other. Over time, they have changed a lot to fit new car needs.

Traditional vs. Modern Connectors

Old connectors did basic jobs. They connected electrical circuits well but had simple designs. Newer connectors have changed for high-tech cars. They now have better locks and sensors built-in. These changes make sure connections are safe and can find problems like overheating early.

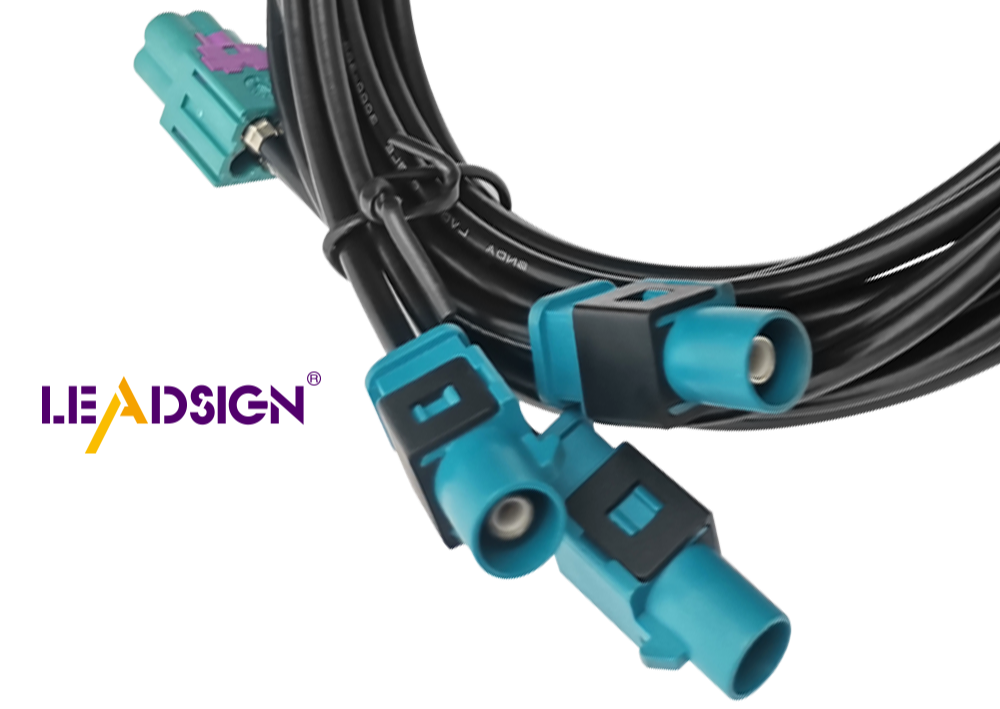

Specific Types and Their Uses

There are many kinds of wire connectors used today, each for special jobs:

IDC (Insulation Displacement Crimp) Connectors: These are popular because they help make harnesses faster. They need fewer parts, making work quicker. But engineers must check how long they last since tests aren't common yet.

Wireless Connectors: These new techs don't need plugging in like old ones do. They let parts move more freely, which is great for electric cars. Wireless power makes things safer by reducing wear on parts.

TE Connectivity Connectors: Made for electric cars, these offer strong sensing and linking solutions. They're key as electric car use grows.

Future Developments

The future looks bright with new ideas improving connector design and use.

Innovations in Connector Design

Makers work on connectors with better pins and locks. This keeps connections tight so power isn't lost or cut off suddenly, stopping breakdowns. Also, using global rules like ISO/AK helps make connectors that fit many car types worldwide.

Potential Impact on Automotive Industry

New connector designs change the car world a lot. Smaller ones fit tight spaces without losing function, solving space issues in modern cars' electronics. Adding safety features boosts system trustworthiness too, leading to better performance and safety across various car models.

Challenges and Solutions

Environmental Concerns

Impact of Materials on the Environment

Car connectors use materials that can hurt nature. Old plastics and metals cause pollution and waste. As cars get smarter, more connectors are needed, which harms the environment more. The USCAR-20 Standard says connectors must last long but shows how these materials hurt nature.

Eco-friendly Alternatives

Makers now look for green ways to make connectors better for Earth. They use halogen-free flame retardant materials that harm less. These help recycling and match the push for greener cars. Using them cuts pollution and helps a cleaner car industry.

Cost Implications

Balancing Cost with Quality

Making good car connectors costs a lot. Makers need strong, safe connectors but also want low prices. The LV214 Standard makes sure wire ends meet quality rules, raising costs. But high standards are key for safety parts like seatbelts needing good connectors.

Innovations to Reduce Costs

To cut costs, makers find new ways to make cheaper connectors. Using lightweight materials in electric cars cuts costs and boosts efficiency. They make cars lighter and systems work better too. By doing this, makers give good connectors at fair prices, helping all.

The world of car wiring connectors is changing fast. Key trends are making them smaller, tougher, and better at connecting. These changes help electric and self-driving cars work well. People in the industry need to keep up with these changes to stay ahead. Using new tech helps make cars safer and work better. In the future, new materials and designs will be important for making cars more efficient and eco-friendly. This matches the industry's goal for a greener future.

See Also

Essential HSD Connectors for Automotive Sector

Significance of Fakra Connectors in Contemporary Cars

Vital Role of Fakra Connectors in Auto Sector