Emerging Trends in Automotive Wiring Connector Types

Automotive wiring connector types are crucial components in cars, ensuring the seamless operation of electrical systems. As automotive technology advances, different types of wiring connectors are developed to meet evolving requirements. The global market for automotive connectors is projected to reach $15.2 billion by 2030, with an annual growth rate of 5.4%. This growth underscores the significance of connectors in modern vehicles. Additionally, the automotive industry is increasingly focused on sustainability, introducing eco-friendly options and collaborating to reduce environmental impact.

Miniaturization in Automotive Wiring Connector Types

Why Make Connectors Smaller

Saving Space in Cars Today

Cars today need to be smaller and work better. Car makers try to use space well, so they make automotive wiring connector types smaller. Tiny connectors help fit more parts in small spaces, making cars work better. This matches the goal of making cars look sleek and move smoothly.

Need for Lighter Parts

Car companies want cars to use less fuel and go faster. Light parts help with this. By shrinking the size and weight of automotive wiring connector types, car makers help make cars lighter. This helps cars save fuel, handle better, and speed up faster.

Effects on Making and Designing

Keeping Good Performance

Making things smaller can be hard for keeping good performance in automotive wiring connector types. Small connectors still need to connect well, handle tough conditions, and be safe. Engineers must find ways to keep them small but working well by using smart designs and materials.

New Ideas in Materials and Design

To solve these problems, there are new ideas in materials and design. Makers create new materials that last long, conduct electricity well, and are light. Cool design tricks like modular systems help use space smartly. These ideas ensure tiny automotive wiring connector types meet today's car needs.

Scientific Research Findings: Scientists keep finding green options that cut down harm to nature but still work great. Following rules about the environment is key for car engineers.

Making automotive wiring connector types smaller shows how much the industry cares about new ideas and being green. As cars get more advanced and eco-friendly, the need for tiny connectors will keep growing.

More Use of Fast Data Automotive Wiring Connector Types

Reasons Why

More Connected and Self-Driving Cars

Cars are becoming more connected and can drive themselves. These cars need strong communication systems to work well. Automotive wiring connector types help these systems by allowing easy data sharing between parts. As cars drive themselves more, the need for connectors that move data quickly grows. This shows why making connectors for complex car data is important.

Need for Quicker Data Movement

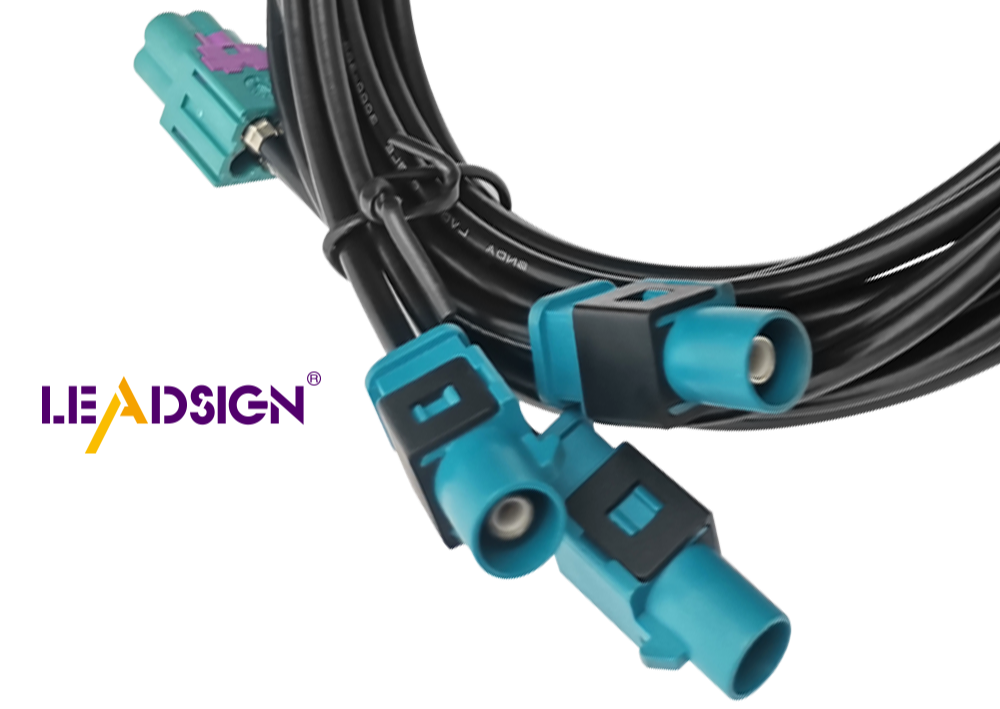

Today's cars need fast data movement for things like maps, music, and helping drivers. Faster data needs special automotive wiring connector types. High-Speed Data (HSD) connectors are made for this job. They work better than old Fakra connectors used in Europe because they handle fast tasks well. This shows the focus on improving how cars send data as they change.

Effects on Car Making

New Connector Rules

Using fast data connectors means new rules in car making. Makers must follow new rules to make sure different cars work together well. These changes affect how automotive wiring connector types are made, needing money spent on new ideas. By following new rules, companies make connectors that fit today's tough car needs.

Fitting with Old Systems

Putting fast data connectors in old car systems has challenges and chances to improve. Makers must make sure new automotive wiring connector types work with old parts but still do better jobs. This needs careful planning and testing so cars keep working right. Good fitting makes cars run better and gives drivers cool features.

Industry Insight: Moving to fast data connectors shows the car world's push for new ideas and doing better jobs. As cars get more connected and smart, the need for top-notch connector solutions will grow.

Adoption of Green Automotive Wiring Connector Types

Car makers now care more about being green. They use eco-friendly automotive wiring connector types. This change is due to strict rules and what buyers want. It means new ideas in making parts.

Environmental Concerns

Rules on Bad Chemicals

Governments make laws to cut bad chemicals in car parts. These rules help keep the earth clean and people safe. Car makers must follow these rules by using safer materials for connectors. Doing this keeps cars safe and helps the planet.

Buyers Want Green Products

People today like green products when they buy things. They want cars with eco-friendly parts, like automotive wiring connector types. This makes companies create better products that are good for nature. By doing this, they sell more and help the earth.

New Material Ideas

Using Break-Down Materials

Car makers try using materials that break down over time for connectors. These materials make less trash and are better for nature. Using them shows companies care about being green and smart.

Making Reusable Connectors

Reusable connectors are a big step in green car parts. They can be used again, saving resources and cutting waste. Making these needs teamwork from everyone who makes car parts. By focusing on reuse, companies help the environment.

Industry Insight: Being green with car connectors needs teamwork from all part makers. Working together ensures new designs meet earth-friendly goals, helping make cars greener.

Using eco-friendly automotive wiring connector types shows how much the industry cares about being green and smart with designs as rules get stricter and people want greener options.

Strong and Reliable Automotive Wiring Connector Types

Why They Matter in Tough Places

Automotive wiring connector types need to be strong in tough places. They must work well even when it's very hot or cold. Hot and cold weather can make them not work right. Makers build connectors to handle these changes, so they always work.

They also need to stand up to shaking and wetness. Cars shake a lot on roads, which can break connectors. Rain or wet air can cause rust or short circuits. To stop this, makers create strong connectors that don't break from shaking or water.

New Technology Helps

New technology makes automotive wiring connector types better and stronger. Better seals are a big help now. These seals keep dust and water out of connectors, so they stay working well. With good sealing, makers make sure connectors are safe in all kinds of weather.

Special coatings also help connectors last longer. These coatings protect against things like rust and wear out less quickly. By using these coatings, makers make sure connectors stay strong for a long time.

Patents and Technical Documents: The Robust filter connector with superior mechanical performance shows these new ideas. It has special filters and ground barriers that make it work better mechanically. These cool ideas show how much the industry wants strong and reliable connectors.

In short, making automotive wiring connector types stronger shows how much the industry cares about making parts that last in tough places. With new tech, makers keep making better connectors for today's cars.

The blog talked about important trends in car wiring connectors. These trends are making them smaller, faster at sending data, eco-friendly, and tougher. Each trend shows how the industry wants to be new and green.

In the future, car connectors will aim to cut down on environmental harm and help electric cars. Engineers should focus on green designs to make a cleaner world.

To sum up, these trends not only make cars work better but also help the car industry become more earth-friendly.

See Also

Exploring HSD Connectors in Automotive Technology

Significance of Fakra Connectors in Today's Cars

Critical Role of Fakra Connectors in Auto Sector