Emerging Trends in Auto Wire Connector Types and Technologies

Automotive electrical connectors types are crucial components in vehicles. They facilitate communication between various car systems. With advancing technology, different types of connectors are being developed to meet the evolving needs of the automotive industry. The market for automotive electrical connectors is experiencing rapid growth, projected to increase from $6.5 billion in 2022 to $11.68 billion by 2030. This highlights the significance of staying informed about the latest connector trends to stay abreast of the advancements in automotive technology.

Overview of Car Wire Connectors

Basic Functions and Importance

Car wire connectors are very important in today's cars. They help different parts, like the engine and radio, talk to each other. These connectors move power and information, which helps the car work well.

Role in Car Systems

Connectors are like the backbone for a car's electrical circuits. They join parts together so they can work as a team. For example, they send signals from sensors to the car's main computer for quick data use.

Impact on How Cars Work

How well a car works depends a lot on its connectors. Good connectors make sure electric systems don't fail. This means the car runs better because everything works without stopping.

Old vs. New Connectors

Car wire connectors have changed a lot over time. Old ones were often metal and very strong. But new ones use better materials and designs for modern cars' needs.

Changes in Connector Designs

Connector designs have changed to fit more complex car systems. New designs focus on keeping signals clear and managing heat well. These changes help them handle more data and power, which is needed for new car tech.

Comparing Materials Used

The stuff used in making connectors has also changed. Old ones used mostly metal for toughness in bad weather. Now, new ones use plastics that insulate better and protect more, meeting new cars' safety needs.

New Trends in Connector Types

Smaller and Compact Designs

Car connectors are getting smaller. Designers want to make tiny parts with many features. This change is because cars need to be strong, fast, and small. Tiny connectors save space in cars, which is important as more gadgets are added.

Good Things About Tiny Connectors

Small car connectors have many good points. They use less room, so more parts can fit in a car. This helps as cars get more gadgets inside them. Also, lighter connectors help the car weigh less, saving fuel. The move from 1.5mm to 0.50mm shows how the industry wants denser solutions.

Problems with Making Them Small

Making tiny connectors isn't easy. They need careful design to work well and last long. As they shrink, keeping them strong and able to handle lots of power is tricky. Designers must make sure these small parts survive tough car conditions like heat and shaking.

Fast Data Connectors

Cars need fast data sharing now more than ever. New systems need quick data swaps to work right. Car connectors must change too for better communication between parts.

Need for Quick Data Moves

As cars connect more, they need faster data moves. Systems like ADAS and entertainment require quick data flow without delay. Fast connectors help these systems give real-time info for a better drive.

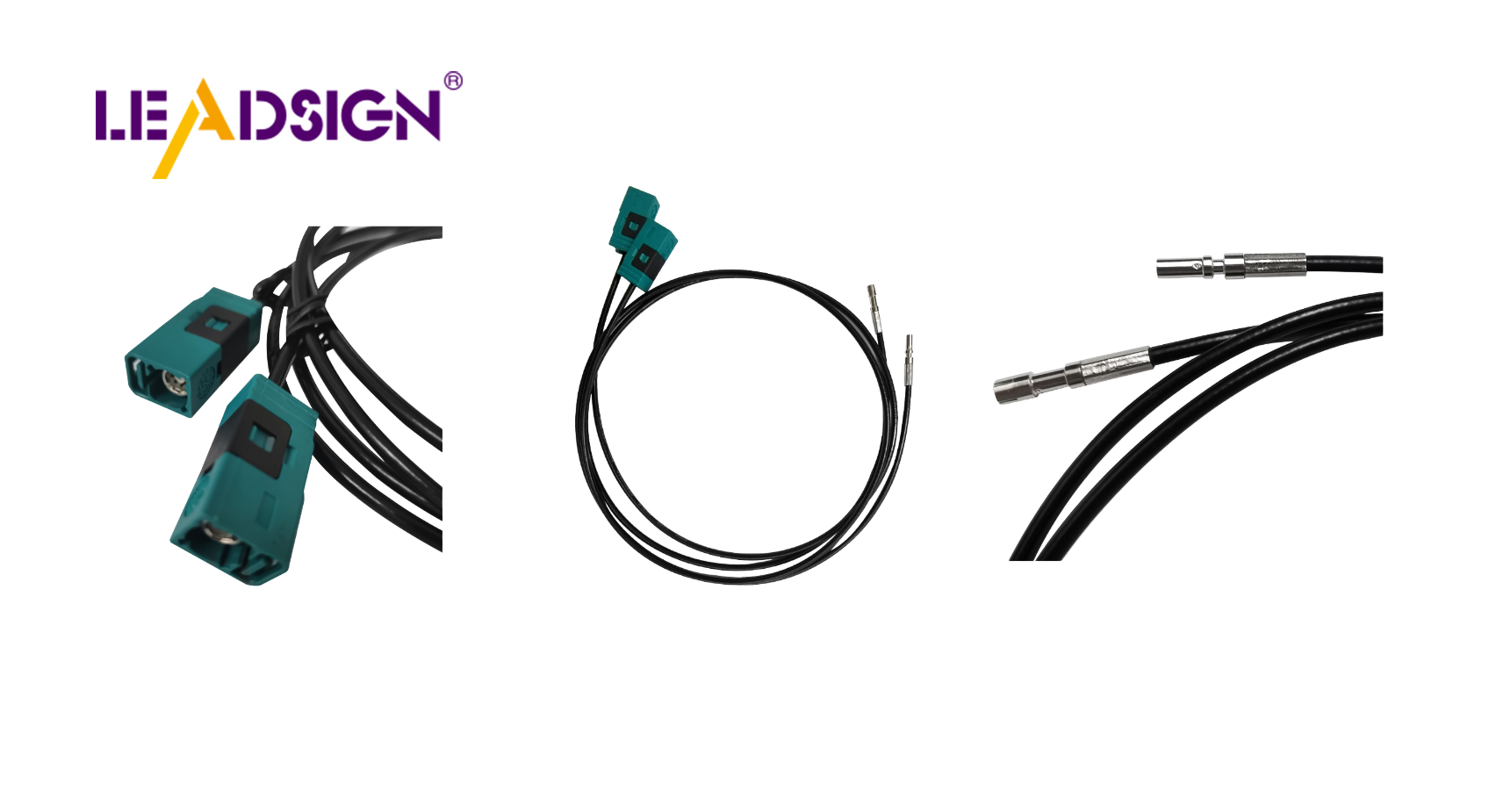

Examples of Fast Connectors

Some car connectors are made for speedy data transfer. Fiber optic ones send data faster than old copper types do. They offer the speed needed for today's tech in cars. Also, FAKRA connectors are used for high-speed tasks like GPS and radio signals.

New Tech in Connector Technologies

Cars keep changing, and so do the smart connectors with IoT. These changes help cars work better, stay safe, and connect more. Two big improvements are smart connectors with IoT and making them last longer.

Smart Connectors with IoT

Smart connectors are a big step for car connectors. They use Internet of Things (IoT) to help cars talk to other devices.

What Smart Connectors Do

Smart connectors have cool features:

IoT Communication: They let cars link easily with gadgets, making a network. This helps with things like voice control.

Security: With IoT, keeping data safe is key. Smart connectors use ways to protect info.

Fast Data Work: They help process data fast, which is important for new car systems needing quick info.

How Cars Use Them

Smart connectors are used in many car parts:

ADAS Systems: They move data quickly between sensors and controls, helping ADAS react faster.

Entertainment Systems: By sending data fast, they make in-car fun and maps work better.

V2X Communication: These connectors let cars talk to roads, other cars, and people for safety.

Stronger and More Reliable

As cars get more complex, we need stronger car connectors. Better materials and tough tests help improve them.

New Materials Used

New materials make strong connectors that handle tough conditions:

Polymers: New plastics insulate well and resist heat, keeping them working right.

Metal Alloys: Special metals make them strong and good at carrying power.

Testing for Quality

To ensure good car connectors, makers test them hard:

Environment Tests: Connectors face heat, wetness, and shaking tests like real life.

Lifecycle Tests: Makers check how long they last to meet standards.

These new techs in car connectors not only boost how cars work but also open doors for future ideas in the auto world.

Future Possibilities and New Ideas

Possible Changes in Connector Technology

What Might Happen Soon

The future for car connectors looks bright with many cool changes coming. Molex Report, a top expert in connectors, says we will see amazing electronics improvements soon. These changes will make cars connect better, work more efficiently, and be safer. As cars get smarter, connectors need to handle more data and power. This means new connectors will be smaller, work better, and manage complex data well.

Effect on Car Industry

These new changes will greatly affect the car industry. Better connectors will help add smart systems like ADAS and fun tech inside cars. This makes driving safer and more enjoyable. Also, as electric and self-driving cars become popular, there will be a big need for new connector ideas. So, makers must change fast to keep up with these needs in a fast-changing market.

Problems and Chances

Solving Technical Problems

Even with a bright future, some technical problems need fixing. Making tiny connectors is good but hard because they must stay strong and reliable. Designers have to make sure these small parts can handle tough conditions like heat and shaking in cars. Plus, using wireless tech means connectors must talk smoothly without messing up signals. Fixing these issues is key for next-gen car connectors to succeed.

Market Chances for Makers

The changing world of car connectors gives many chances to makers. As more people want electric and self-driving cars, companies can benefit by making advanced connection solutions. Mordor Intelligence says companies are creating better connections with safety features to meet these needs. By putting money into research and making new products, companies can lead the market while helping the car industry grow.

The blog looked at important changes in car wire connectors. It talked about making them smaller, faster, and smarter. Knowing these changes is very important for people in the car business.

"People in the industry need to try new things, spend on research, and work together to keep up with changes."

Doing this helps them succeed for a long time and make the most of new chances in car connections. Trying new ideas will help the car world grow, especially for electric and self-driving cars that need better connections and safety.

See Also

Enhancing Automotive Connectivity: Benefits of HFM Connectors

Benefits of HFM Connectors for Automotive Applications

Maximizing Automotive Data Transfer: Advanced Connectors and Cables

Significance of Fakra Connectors in Automotive Applications

Significance of Fakra Connectors in Modern Vehicle Technology