Creating DIY Projects with Auto Wire Connector Types

Automotive electrical connectors types are essential for DIY car projects, which are increasingly popular. Many individuals choose to repair or modify their vehicles independently. Selecting the appropriate wire connectors is crucial for ensuring safety and optimal performance in these tasks. Engaging in such projects not only enhances your skills but also boosts your confidence. Whether you are a seasoned enthusiast or a beginner, understanding the various automotive electrical connectors types is fundamental to successfully completing your automotive projects.

Understanding Automotive Electrical Connectors Types

When starting DIY car projects, knowing the different automotive electrical connectors types is key. These connectors help your car's electrical parts work well and safely. Let's look at some common types and how to pick the right one for your project.

Exploring Common Automotive Electrical Connectors Types

Butt Connectors

Butt connectors are often used in car wiring. They link two wires end-to-end, making a smooth connection. You put the wire ends into the connector and crimp them tight. This connector is great for fixing or adding wires without changing the original setup.

Spade Connectors

Spade connectors, or fork connectors, are good when you need to connect and disconnect wires often. Their fork shape makes it easy to insert and remove from blocks. Use spade connectors with things like speakers or switches that need quick disconnection.

Ring Connectors

Ring connectors give a strong and lasting connection. They have a round end that fits over bolts or screws tightly. These are perfect for grounding or connecting wires to battery ends. Their design stops accidental disconnections from shaking or movement.

Selecting the Right Connector for Your DIY Project

Picking the right connector means thinking about several things to make sure your project works well.

Key Factors to Consider

Environment: Will your connectors face hot, cold, or wet conditions? Pick ones made for these situations.

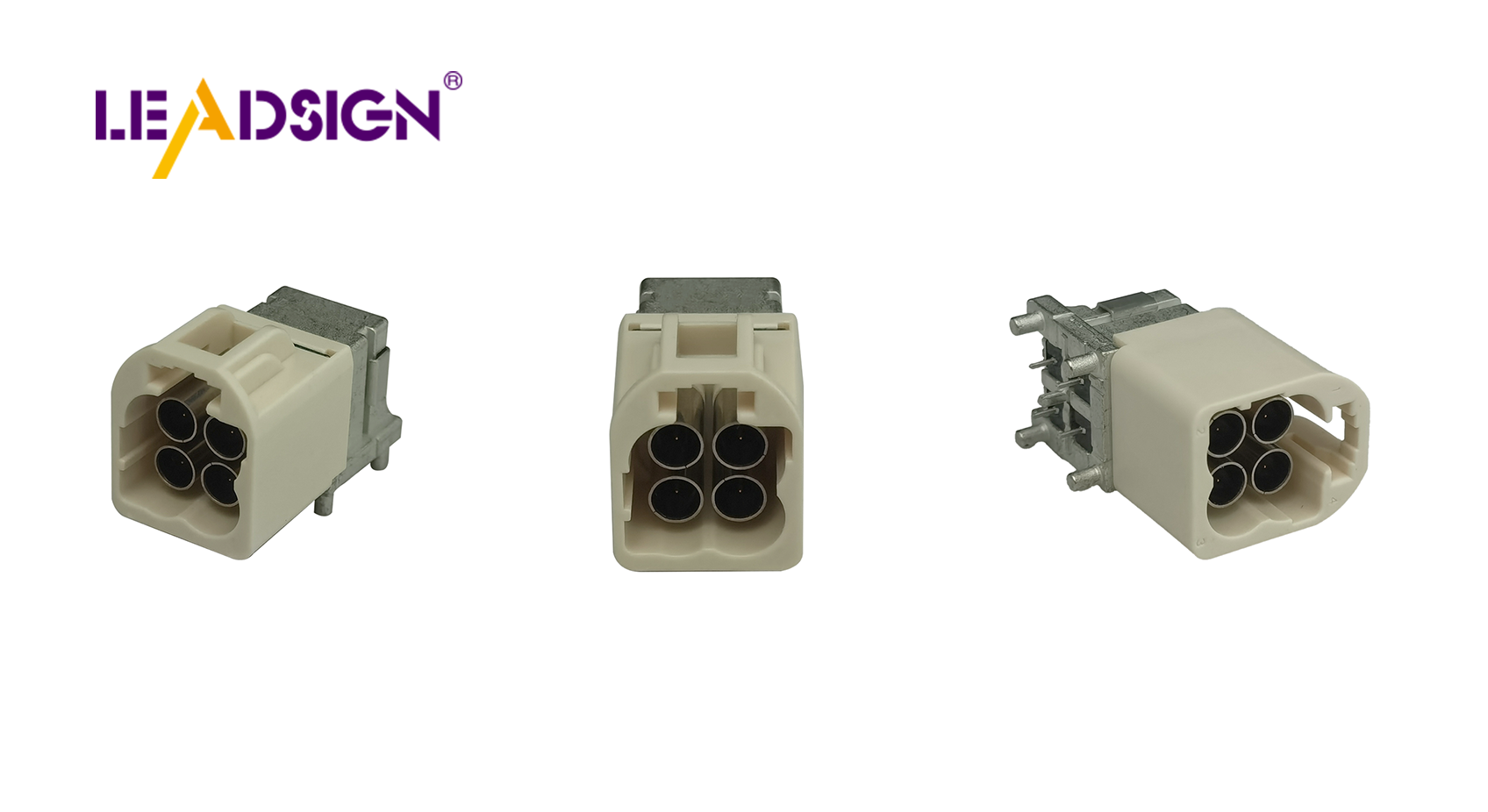

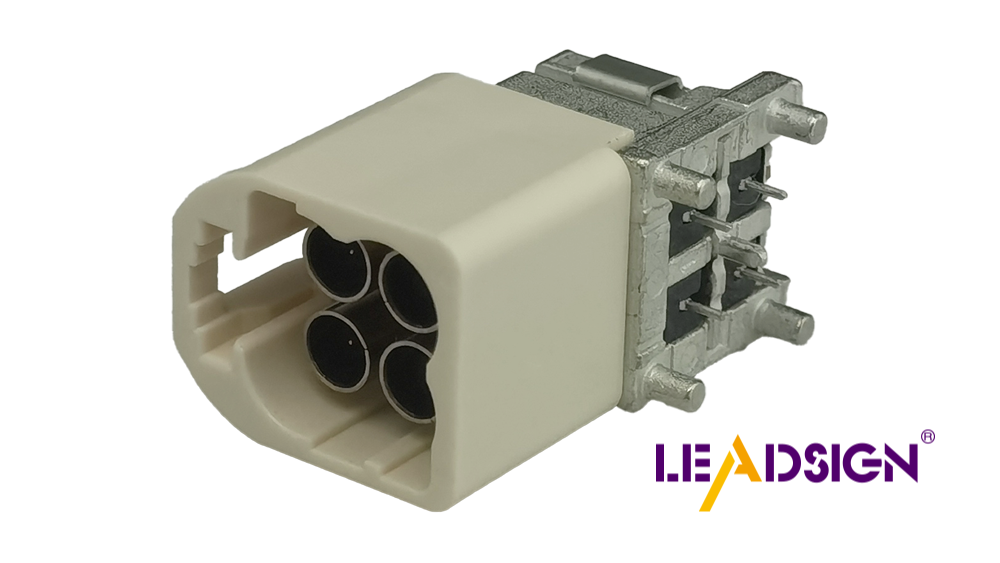

Material: Choose plastic housings for light jobs or metal for tough tasks.

Contact Resistance: Find connectors with low-resistance materials like gold to keep signals strong.

Pin Density: More pins mean more connections possible later on.

Evaluating Pros and Cons of Different Connectors

Butt Connectors: Simple but not good if you disconnect often.

Spade Connectors: Easy changes but might loosen if not tight enough.

Ring Connectors: Strong hold but need tools to put on and take off.

By learning about these automotive electrical connectors types, you can choose smartly for your DIY projects. Whether fixing, upgrading, or customizing, the right connectors keep your car's electric parts working well and reliably.

Getting Ready for Your DIY Project

Prepare well for your DIY car project. Gather the right tools and plan smartly. This helps things go smoothly.

Collecting Tools and Materials

Before you start, have all the needed tools and materials ready. This step is important for doing a good job.

Important Tools You Need

Here are some basic tools:

Automotive Wire Strippers: These help cut wires neatly without harm.

Crimping Tool: A good crimper makes tight connections. Cheaper ones need two steps; expensive ones do it in one.

Multimeter: Use this to check electrical numbers and find problems.

Wiring Testers: Make sure your connections work with these.

"Using the right wiring tools makes the job easier and keeps wiring trouble-free." - Expert advice

Best Materials to Use

Picking good materials matters a lot:

Connector Kits: Choose the type like Molex or Deutsch, then get a kit.

Pins and Seals: Buy many at once so you don't run out.

Heat-Shrink Tubing: Protect your connections with this.

"Once you decide what to use, get a kit or pieces from many places." - Practical tip

Planning Your Project Well

A solid plan is like a map to success. It keeps you organized.

Setting Clear Goals

Start by making clear goals:

What do you want to do?

Are you fixing, upgrading, or changing?

Clear goals guide your choices and keep you focused.

Making a Step-by-Step Plan

Break your project into easy steps:

Research: Learn about your car's electrical parts and connectors.

List Tasks: Write down each task you must finish.

Timeline: Set times for tasks to stay on track.

Checkpoints: Check progress often and change plans if needed.

"Practice making strong crimps before starting the job. It's easy after two or three tries!" - Encouragement from experienced DIYers

By getting the right tools, materials, and planning well, you're ready for a great DIY car project. Remember, being prepared leads to success and fun!

Doing Your DIY Project

Now you're ready to start your DIY project. Use what you know about car wire connectors. This part helps you use them well and fix any problems.

Guide to Using Car Wire Connectors

Stripping and Preparing Wires Right

Before joining wires, strip them right. Use a good wire stripper to take off the cover without hurting the wire. Hold the wire tight, squeeze the tool gently, and pull off the cover smoothly. This step is key for a strong link.

Ways to Join Wires with Connectors

After stripping, connect wires. Pick the right connector type for your job. Butt connectors join two wires in a line. Put stripped ends in it and crimp tight with a tool. Make sure it's snug to avoid electric troubles.

Spade connectors are best if you often join and unjoin wires. Slide it into place firmly. Ring connectors hold strong by fitting over bolts or screws tightly.

Making Sure Connections Are Safe

Test connections after joining wires to make sure they're safe. Use a multimeter to check if electricity flows well. If numbers aren't right, fix your links as needed. Testing keeps your project working safely.

Fixing Common Problems

Even when careful, problems can happen. Knowing how to spot and fix them helps your project succeed.

Finding Problems

If things don't work right, find out why first. Check each link for loose or bad contact points using your multimeter to see if power moves correctly through parts.

Easy Fixes and Tips

Once you find what's wrong, fix it easily by re-crimping loose links tighter or swapping bad ones with new ones like Deutsch connectors known for being strong under different conditions ensuring they last long term.

"Picking connectors based on where they'll be used makes them last longer." - Expert advice

Skip solderless types if unsure about their strength; choose those that stay connected well instead.

By following these steps and tips, you'll do your DIY project confidently using car wire connector types right for success!

Picking the right connectors is very important for your DIY projects. They keep things safe and working well. As you try new ideas, remember each project helps you learn. Don't be afraid to experiment.

"If these connectors work well and reduce mistakes, they might be worth using."

Share your stories or ask for help if needed. Your journey can inspire others. Let's keep talking and make every project great!

See Also

Discovering the Advantages of Fakra Car Connectors

Transforming Car Connectivity: The Benefits of HFM Connectors

An In-depth Look at HSD Connectors