How to Distinguish Car Wire Connector Types for Beginners

Understanding automotive electrical connectors types is crucial for car projects. These connectors simplify the process of joining wires compared to soldering. However, beginners often struggle to identify the different types of connectors and create robust connections. Over time, connections can deteriorate due to weather conditions, making the selection of the appropriate connector essential. This guide assists you in addressing these challenges, ensuring your car's electrical components function effectively.

Understanding Car Wire Connectors

What are Car Wire Connectors?

Meaning and Job

Car wire connectors are important parts in your car's wiring. They link wires together, making sure electricity flows well. This is key for your car to work safely and properly. When you turn on something, these car wire connectors help make it happen. Without them, your car wouldn't work right.

Why They Matter in Cars

In today's cars, these connectors are super important. They join systems like the engine and sensors. This helps share information so your car works well and safely. As cars get more advanced, we need more of these connectors. They keep your car running smoothly even when things get bumpy.

Common Types of Car Wire Connectors

Knowing about different wire connectors helps when fixing cars. Here are some types:

Blade Connectors

Blade connectors are flat metal pieces that fit into slots. They're simple to use and hold tight. You see them where quick unplugging is needed, like fuse boxes.

Bullet Connectors

Bullet connectors look round like bullets and fit into sockets snugly. They're used in car lights and low-power spots.

Butt Connectors

Butt connectors connect two wires end-to-end securely. Use them to extend or fix wires in car harnesses.

Pin Connectors

Pin connectors have many pins in one place for complex setups needing lots of links, like engine controls.

Learning about these connector types helps you fix cars confidently by picking the right one for safe electrical work.

Tools and Materials Needed

When fixing car wires, right tools matter. They help make strong connections. Let's see what you need.

Important Tools

To work with car wire connectors, some tools are key. These tools help cut, join, and check wires easily.

Wire Strippers

Wire strippers take off the plastic cover on wires. They show the metal inside without harm. This is important for joining wires. Pick a stripper that fits your wire size. It makes work fast and neat.

Crimping Tools

Crimping tools press connectors onto wires tightly. They make sure the connection stays firm. Find a crimper that matches your connector type. This ensures it works well.

Multimeter

A multimeter checks if connections are good. It tests voltage and current flow in wires. Use it to find problems and ensure everything works right.

Suggested Materials

Besides tools, some materials improve your work's quality.

Connector Kits

Connector kits have different wire connectors in one set. They come in many sizes for various uses. Having a kit means you're ready for any task.

Heat Shrink Tubing

Heat shrink tubing covers connections after joining them. Heat makes it shrink tight around the joint, keeping water out and preventing rust.

With these tools and materials, you can fix car wiring confidently. Your connections will be safe and reliable.

Easy Steps to Spot Connectors

Finding car wire connectors might seem hard, but it's not. With some help, you can learn it easily. Let's make it simple.

Look Closely

First, look closely at the connector. By seeing how they look, you can tell what type they are.

Shape and Size

Check the shape and size of the connector. They come in shapes like rectangles or circles. Big ones might carry more wires or power. Small ones might be for tiny jobs. Notice these things to know what they do.

Color Clues

Next, see the colors on them. Many connectors use colors to show what they do or connect to. Red could mean positive; black might mean ground. Knowing these colors helps you pick the right one.

Test How They Work

After looking at them, test if they work right.

Check Connection

Check if electricity flows through it well. Use a multimeter set to check flow. Put probes on each end of the connector. If it beeps, it's good! If not, there may be a problem with the wire or connector.

Check Voltage

Make sure it gives the right voltage too. Set your multimeter to check voltage levels. Attach probes to correct spots and see if numbers match what's needed for that circuit.

By doing these steps, you'll know about car wire connectors better and fix cars easier.

Now you know about car wire connectors and the tools to use. It's time to practice. Try small projects to get better. This will make you more confident.

"The old connectors were easy once you knew them," says the Old Cars Review Team. Look at Wago's small splicing connectors, which need no special tools.

For more help, watch online videos and visit car forums. These can give useful advice and tips. Have fun connecting!

See Also

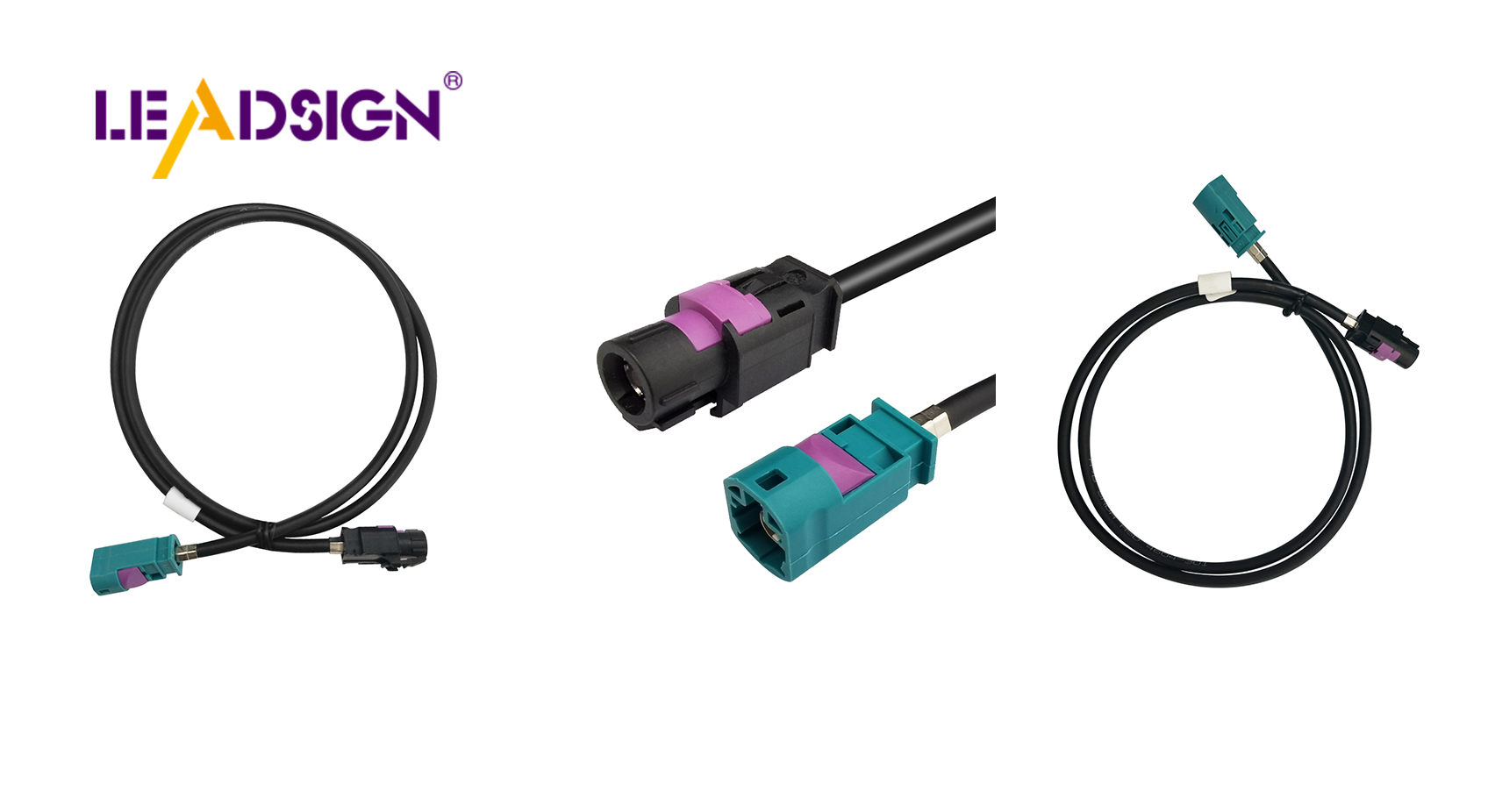

An In-Depth Look at Fakra Connectors: Fundamentals, Varieties, and Uses

Exploring HSD Connectors in the Auto Sector

All About Fakra Male Connectors: A Detailed Overview

Navigating Ford Fakra Connectors: Everything You Need to Know