How to Distinguish Different Types of Wire Connectors Automotive

Understanding automotive electrical connectors types is crucial for anyone involved in car repairs. These connectors ensure the efficient functioning of electrical systems, which is vital for maintaining vehicle safety and performance. Differentiating between various automotive electrical connectors types can be challenging due to their diversity. This guide provides clear information and practical advice to assist you. By familiarizing yourself with these connectors, you can enhance your skills and ensure that car repairs and maintenance are performed correctly.

Understanding Automotive Electrical Connectors Types

Definition and Function

What are wire connectors?

Wire connectors are important parts in car electrical systems. They link wires together to keep them connected well. There are different types of these connectors, each made for certain jobs in the car's wiring. Using the right connector keeps the electrical system working properly, stopping problems like short circuits or losing power.

Why are they important in automotive systems?

In cars, wire connectors help all parts work well together. They make sure power and signals move smoothly between parts. Without good connectors, things like lights, music systems, and engine controls might not work right. This is very important in new cars with advanced systems like ADAS (Advanced Driver Assistance Systems) that need perfect connections.

Common Automotive Electrical Connectors Types

Knowing about different wire connectors helps you pick the best one for your job. Here are some common ones:

Butt Connectors

Butt connectors join two wires end-to-end. They are great for connecting wires in cars. You can get them in many sizes to fit different wires. These connectors hold wires tight even if there's shaking.

Ring Terminals

Ring terminals have a ring-shaped end that fits over bolts or studs. They're used for grounding or connecting to terminal blocks. The ring shape makes a strong connection that won't come loose easily.

Spade Terminals

Spade terminals look like forks and let you connect and disconnect from terminal blocks easily. They're handy when you need to take wires off often but still want a solid connection.

Bullet Connectors

Bullet connectors have male and female ends that snap together quickly. They're used where quick disconnection is needed, especially in tight spaces.

Quick Disconnects

Quick disconnects let you connect and disconnect wires fast. They're used where frequent changes happen in car electrical systems because they come in many styles for different uses.

By knowing these connector types, you can make sure your car's electrical system works well. Whether fixing something simple or doing a big installation, picking the right connector is key for strong connections.

Finding Different Wire Connectors

Knowing how to find different car wire connectors is important. This part will show you ways to identify them, so you can pick the right one.

Looking at Them

Colors

Colors help spot different car wire connectors. Makers use colors to show what a connector does or its wire size. Red ones are for small wires, while blue or yellow ones are for bigger wires. Learning these colors helps you choose the right connector fast.

Shapes and Sizes

The shape and size of connectors also help us know them. Car wire connectors come in shapes like round, square, or flat. Each shape has a job and fits certain parts. The size tells us how much power it can handle. Big connectors carry more power for tough jobs.

What They're Made Of

Metals

The metal in connectors affects how they work and last. Common metals are copper, brass, and aluminum. Copper is great for carrying electricity in cars. Brass fights rust well, and aluminum is light and cheap. Knowing these metals helps pick the right connector for your car's needs.

Covering Materials

Covering materials keep connectors safe from weather and electric problems. Car wire connectors have covers made of PVC, nylon, or heat-shrink stuff. PVC gives basic safety; nylon lasts longer and resists chemicals; heat-shrink seals tight against water and dirt. Picking the right cover keeps connections strong.

Where They Are Used

Engine Area Connectors

Connectors in engines face tough spots with heat and shaking. These need strong builds and locks to stay connected under stress.

Inside Car Connectors

Inside car connectors are different from engine ones. They focus on being easy to use and looking nice inside cars.

By learning these tips, you can find the right car wire connectors easily.

Tips for Picking the Right Wire Connector

Things to Think About

Choosing the right wire connector keeps your car safe and working well. Here are some important things to think about:

How Much Power is Needed

Know how much power your car needs. Different connectors carry different amounts of electricity. If a connector can't handle it, it might overheat or break. Always check if the connector can meet your system's power needs.

Where It Will Be Used

Think about where you'll use the connector. If it will face water, heat, or chemicals, pick one with good insulation and material. For example, heat-shrink covers protect well from water and dirt in tough places.

Best Ways to Install

Putting in wire connectors right makes them work better. Follow these tips for best results:

Tools You Need

Get all tools ready before starting. You'll need:

Wire strippers

Crimping tool

Heat gun (for heat-shrink)

Multimeter (to test)

Having these tools helps make installation easy and quick.

How to Install Step-by-Step

Strip the Wires: Use wire strippers to take off about 1/4 inch of cover from wire ends. Make sure wires are clean and not damaged.

Pick the Connector: Choose a connector that fits the wire size and power needs. Ideal In-Sure™ Push-In Wire Connectors join wires easily without twisting.

Put in the Wires: Insert stripped wires into the connector fully so they touch metal inside well.

Crimp It: Use a crimping tool to lock the connector onto wires tightly.

Seal It: With heat-shrink connectors, use a heat gun to shrink cover around connection for extra protection.

Test It: Use a multimeter to check connection for continuity and no shorts or open circuits.

By doing these steps, you ensure strong connections that work well in different conditions. Picking and installing connectors right is key for keeping your car's electrical system strong.

Understanding car wire connectors is important for safety. Picking the right one stops problems like overheating or sparks. Push-in connectors are good for many wires and save space.

"Forget old wire nuts, use Push In connectors."

Use this information to get better at fixing cars. These tips help you choose well and do repairs better.

See Also

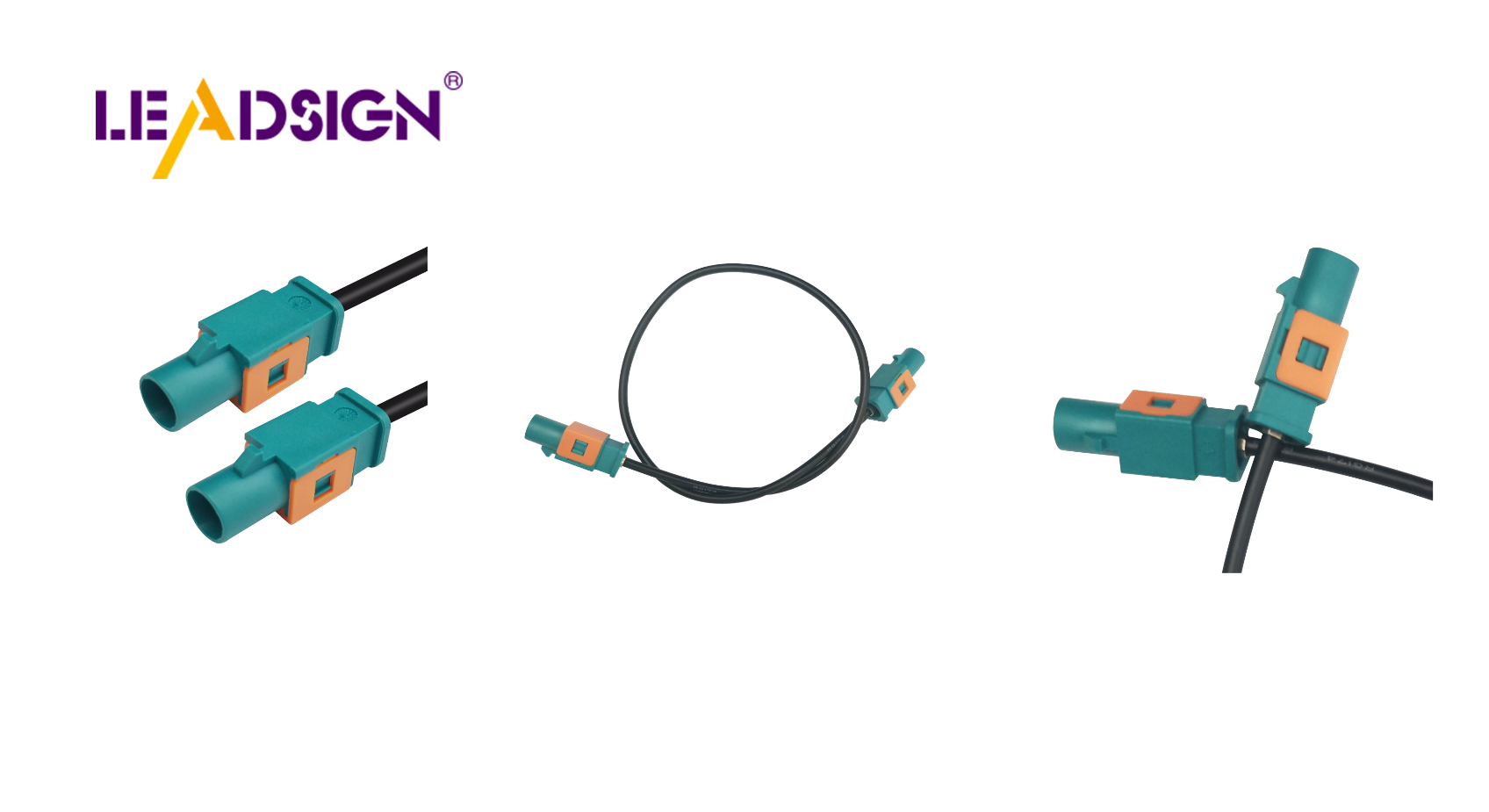

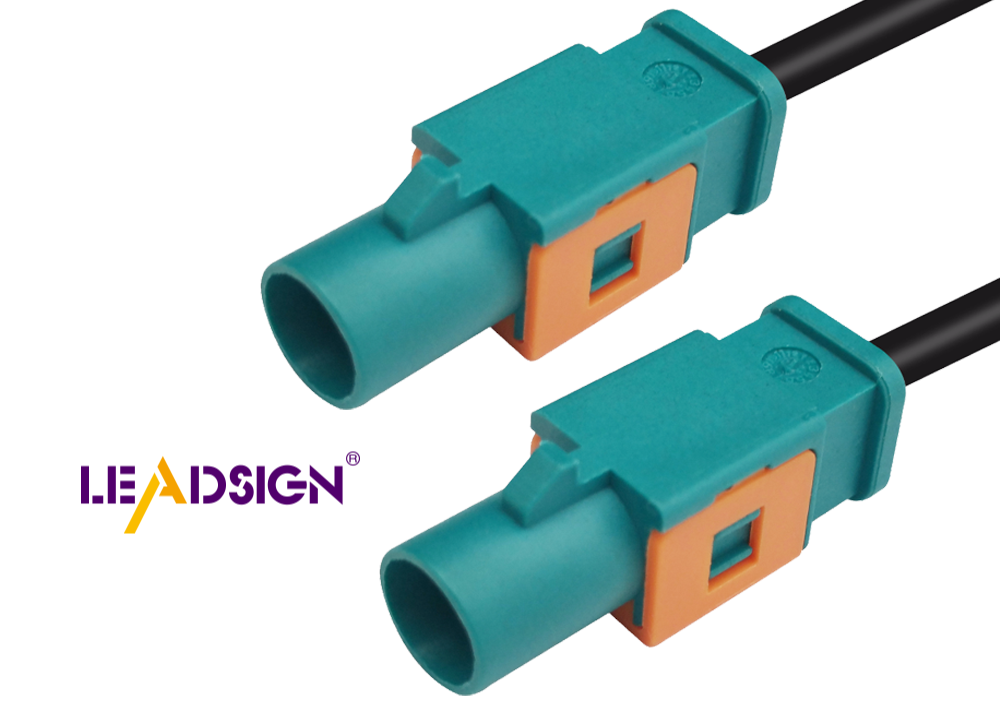

Exploring HSD Connectors in the Auto Sector

Significance of FAKRA Connectors in Auto Uses

Essential Role of Fakra Connectors in Auto Sector