Different Types of Wire Connectors in Automotive Systems

Car wire connector types are important in cars. They help car parts work well. Without good connectors, you might have wiring problems, like with headlights. Using the right connectors makes cars last longer and safer. OEM connectors fit certain cars and handle tough conditions. They also save money by being reliable. Knowing about these connectors helps keep your car safe and running well.

Car wire connectors are important for your car's electrical system. Each type has a special job and benefits. Let's look at some common ones.

Crimp connectors are popular because they work well and are easy to use. They come in different types for different jobs.

Butt connectors join two wires end-to-end, great for making wires longer. Ring terminals attach wires to screws or studs securely. Spade terminals are like ring ones but easier to attach and remove.

Crimp connectors have good points:

Easy to put on with a crimping tool.

They make strong connections that last long.

But there are downsides too:

You need a special tool to install them.

Bad crimping can cause weak connections.

Solder connectors join wires by melting solder, making them strong and conductive.

Heat shrink solder connectors mix soldering with heat shrink tubing for extra safety. Solder sleeves have a solder ring that melts when heated, ensuring a secure connection.

Solder connectors have perks:

They give great electrical flow.

Good in places with lots of movement or shaking.

However, they take more time and skill than crimping. Once done, you can't easily undo them.

Push-in connectors are simple and quick without tools needed. They're used when speed matters most.

Lever nut connectors use levers to hold wires tight. Spring clamp ones use springs to keep wires secure.

Push-in connectors have benefits:

Fast wire connecting without tools.

You can disconnect and reconnect easily.

Yet, they don't fit all wire sizes and aren't as secure in shaky places as other types.

Picking the right car wire connector keeps your car's electric parts working well. Think about what you need before choosing one.

Uses in Car Systems

Knowing car wire connector types is key for keeping your car's electrical parts working. Each part of your car needs special connectors to work best and stay safe. Let's see how these connectors are used in different car systems.

Engine Wiring

Common Connectors Used

In engine wiring, you often find crimp and solder connectors. These connectors give strong links that handle the engine's shakes and heat changes well. OEM connectors are important here, making sure electric links are right and stopping problems. They are made to deal with the tough spots in the engine area.

Installation Techniques

When putting in connectors for engines, make sure they fit tight and right. Use a crimping tool for crimp ones to get a snug fit. For solder ones, heat them evenly to melt the solder for a strong hold. Good installation stops heat problems that can cause short circuits, like when grease was used to stop issues in headlight wires.

Lighting Systems

Common Connectors Used

Car lights often use push-in and bullet connectors. These connectors make quick and easy links, which is important for keeping lights working well. They help connect headlights, taillights, and inside lights easily.

Installation Techniques

For lights, make sure it's easy and works well. Push-in ones need no tools, great for fast fixes. Make sure they fit well to avoid coming loose. Bullet ones have a round shape that makes it easy to plug in and use. Good installation stops problems like flickering or not working at all.

audio systems

Common Connectors Used

In audio systems, terminal blocks and pigtail connectors are common. These help link speakers, amplifiers, and main units together well so sound is clear without breaks.

Installation Techniques

When setting up audio system connectors, aim to keep signal loss low. Terminal blocks let you disconnect easily during maintenance times. Pigtail ones bend easily so they fit tight spaces better. Strong connections stop sound distortion making listening better overall.

Picking the right car wire connector types for each part of your vehicle keeps everything running smoothly and safely too! By knowing what each system needs like engine wiring or lighting systems or audio setups you can keep your car’s electric parts working great!

Common Problems and Fixes

Knowing common problems and fixes with car wire connectors helps you care for your car's electric system. Let's look at some usual issues and how to fix them.

Connection Problems

Why They Happen

Connection problems happen if connectors aren't put on right or the wrong type is used. If they don't fit well, they might come loose, causing bad electric contact. Car movement can also shake connectors loose if not tight.

How to Fix Them

To stop connection problems, pick the right connector for the job. Make sure they fit tightly. Use crimping tools for a snug fit with crimp connectors. Check connections often for wear or looseness. If you see any problem, fix connection problems or change the connector quickly.

Rust Issues

Why They Happen

Rust is common in car wire connectors, especially where there's water or road salt. It happens when metal parts react with things like water, causing rust and damage. This can mess up electric flow and cause failures.

How to Fix Them

To fight rust, use connectors that resist it. OEM ones are strong and good in tough spots. Put grease on them to keep water out. Check for rust often and clean them if needed.

Heat Problems

Why They Happen

Heat in car wire connectors can come from high electric loads or bad connections. If not installed right, they make resistance which makes heat. This heat can harm connectors and wires nearby.

How to Fix Them

To stop heat issues, make sure all connections are tight and secure. Use connectors made for the load they'll carry. For big loads, solder ones work well as they conduct electricity great. Look at connectors often for signs of heat damage like color change or melting and replace if needed.

By knowing these common problems and fixing them right away, you keep your car's electric system working well. Picking the right connector types and taking care of them keeps your car safe.

In this blog, you learned about different wire connectors in cars. Each connector has special uses and benefits. Picking the right one is key for your car's electrical system to work well.

Key Points:

Crimp connectors make strong connections that last.

Solder connectors give great electric flow.

Push-in connectors are fast and easy to use.

Choosing the right connector improves how systems work and stay reliable. Always think about where and how the connector will be used. This keeps your car's electrical system safe and working well.

See Also

Exploring HSD Connectors in Automotive Technology

Benefits of HFM Connectors for Automotive Applications

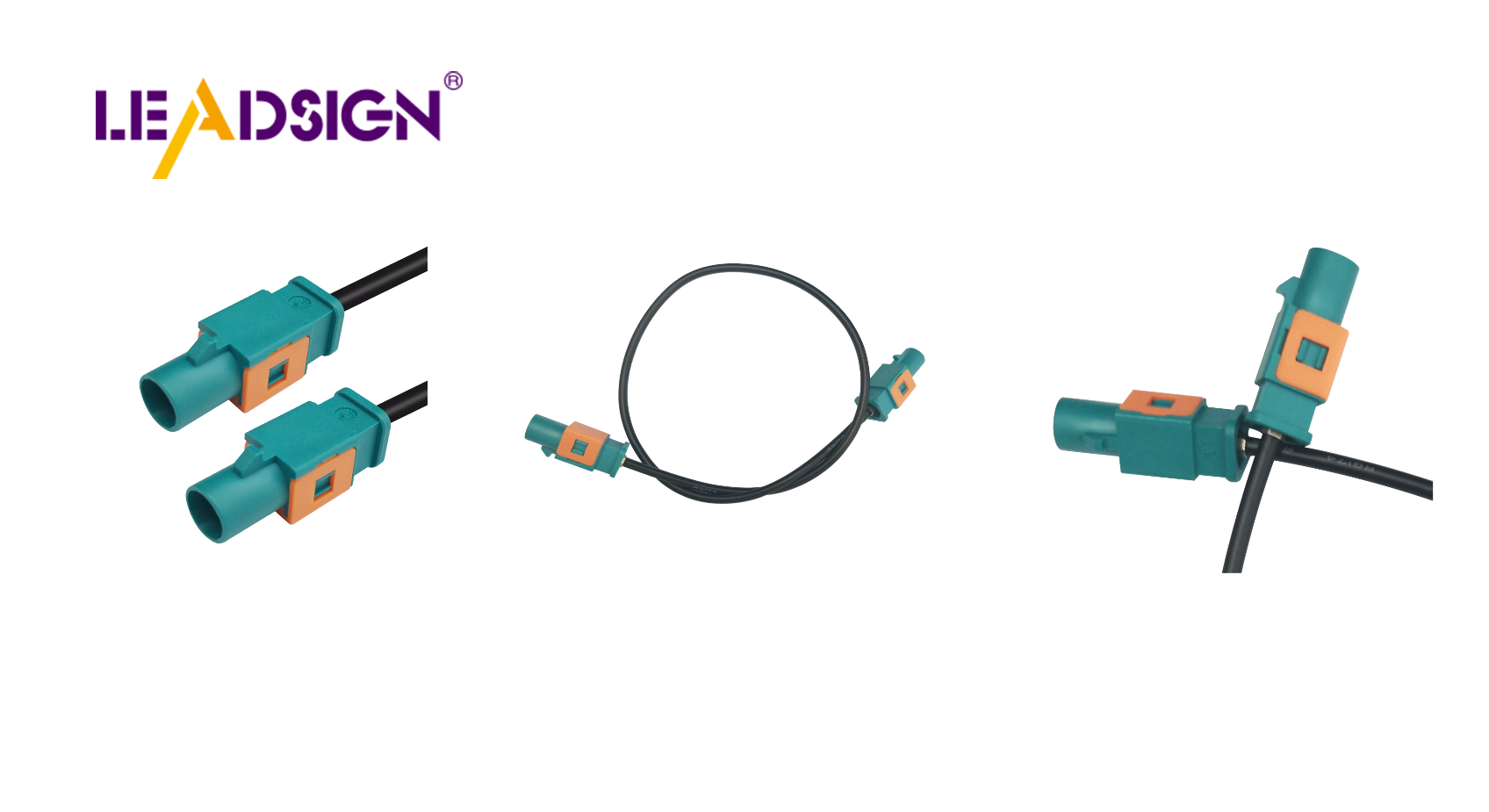

Significance of Fakra Connectors in Auto Sector