Custom Wire Cables: Challenge the Ordinary

In a world full of new ideas, custom solutions are needed. Custom wire cables help solve unique problems in many fields. They are useful in cars, phones, and factories. These cables are made to match your exact needs. They are precise and dependable. For example, IT and space industries use custom cables for tough jobs. Today, making your own cable is much easier. You can design cables that match your needs perfectly.

Key Takeaways

Understand your specific needs before designing a custom wire cable to ensure it performs effectively in its intended environment.

Choose the right online design tools that are user-friendly and offer features like material options and compatibility checks to streamline the design process.

Select appropriate materials and connectors based on the cable's application, ensuring durability and functionality for specific tasks like automotive or telecom use.

Thoroughly review your cable design for accuracy and compliance with safety standards to avoid costly mistakes and ensure reliability.

Save your custom cable design for future use, making reordering and adjustments easier and more efficient.

Invest in quality materials and connectors, as they enhance the performance and longevity of your custom cables, ultimately saving you money in the long run.

Step 1: Know What Your Custom Wire Cable Needs

Making the right custom wire cable starts with knowing your needs. By understanding this, you make sure the cable works well. Let’s go through the steps.

Find Out How and Where It Will Be Used

First, think about where and how the cable will be used. This helps you pick the best design and materials.

Figure out what device or system the cable connects to.

Ask yourself: What will this cable connect? It could be a camera, power source, or data system. Knowing this is very important. For example, car electronics often need cables for High-Speed Data (HSD), like USB or LVDS cameras. Industrial systems may need strong cables for tough jobs.

Think about the environment (e.g., cars, factories, outdoors).

What conditions will the cable face? Will it deal with heat, water, or shaking? Outdoor cables need weatherproof materials. Car cables must be strong and secure, like those in radios or infotainment systems. Matching the cable to its environment makes it last longer.

List the Functional and Technical Details

After knowing the purpose, focus on the technical needs. These details decide how the cable is made.

Choose the length, flexibility, and strength needed.

Measure the length you need but leave some extra. If the cable will bend a lot, it should be flexible. For hard jobs, like in space or hospitals, strength is key. Custom cables let you balance these needs.

Decide what kind of signal or power it will carry (e.g., High-Speed Data, LVDS, Ethernet).

What will flow through the cable? For fast data, like Ethernet or FireWire, you need special cables. If it’s for USB or digital networks, make sure it supports those. Custom cables let you add only what you need, saving money and making them work better.

By knowing your needs, you can create a cable that fits perfectly. This step makes sure your custom wire cable is useful, reliable, and just right for you.

Step 2: Pick Tools and Platforms for Custom Wire Cables

Choosing good tools and platforms is very important. The right ones make designing cables easier and better. Let’s learn how to pick the best options.

Search for Online Cable Design Tools

Online tools help you design custom cables step by step. They make the process simple and fast.

Find tools that are easy to use with previews.

Look for tools that are simple to understand. Easy tools save time and avoid confusion. Some tools show previews of your design as you work. This helps you fix mistakes early. For example, some tools let you drag and drop parts, making it fun and easy.

Check for features like material choices and compatibility checks.

Good tools check if your cable works with your devices. They also warn you about problems, like wrong connectors. Look for tools with many material options. You might need strong insulation for outdoor use or special shielding for fast data.

Compare Costs and Features

After finding tools, compare their prices and features. This helps you pick the best one for your project.

Look at total costs, including materials and extra services.

Check the full price, including materials and shipping. Some tools offer fast shipping if you’re in a hurry. Make sure the cost fits your budget but still gives good quality. For example, spending more on strong materials for car cables can be worth it.

Read reviews to check quality and reliability.

Customer reviews can tell you if a tool is good. Look for comments about how easy it is to use and how well it works. Positive reviews mean the tool is trustworthy. If others in your field recommend it, that’s a good sign.

By picking the right tools and platforms, you can design better cables. These steps make sure your cables are useful, accurate, and fit your needs.

Step 3: Create Your Custom Wire Cable

Making your custom wire cable combines creativity and usefulness. This step helps you choose the best materials and parts. Let’s simplify it.

Pick Cable Type and Materials

The materials decide how well your cable works. Choosing the right ones makes it strong and efficient.

Choose the right wire size, covering, and protection.

Start with the wire size. Thicker wires carry more power, while thinner ones are for less power. Next, pick the covering. It keeps the cable safe from heat or water. For outdoor or car use, choose tough materials. Protection is also important. It blocks outside signals, keeping your data clear. Strong protection is needed for High-Speed Data (HSD) or Ethernet cables.

"Good protection stops outside signals and keeps data clear." – Expert in Custom Cable Making

Use special materials for certain jobs (e.g., cars or telecom).

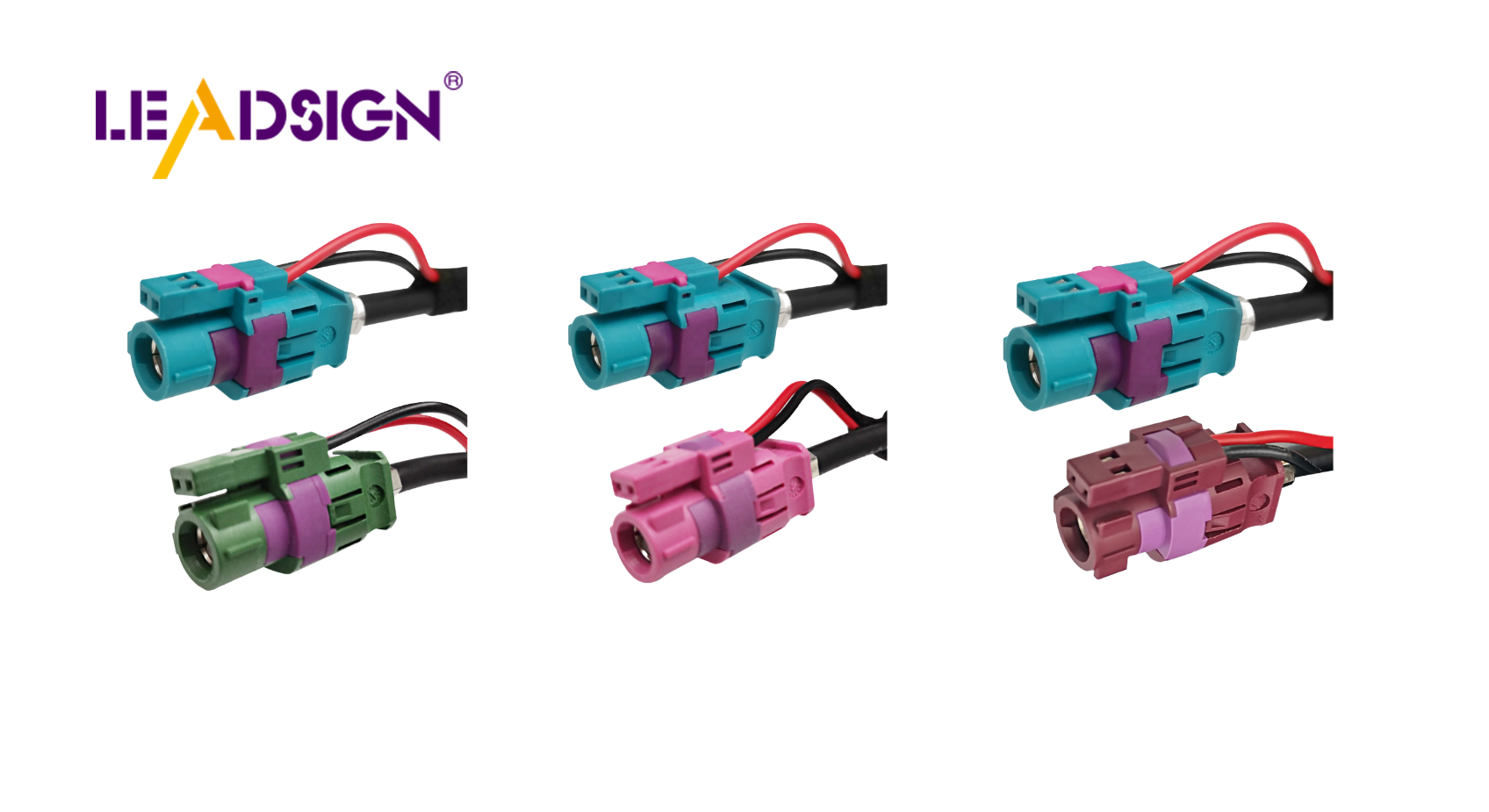

Think about what the cable will do. Car cables need to handle shaking and heat. Telecom cables should be light but strong. Special materials help cables last longer and meet industry rules. For example, HSD connectors in cars need strong materials to work well.

Add Connectors and Extras

Connectors and extras make your cable easy to use and reliable.

Pick connectors that fit your devices (e.g., HSD for car systems).

Choose connectors that match your devices. They must fit perfectly. For car systems, HSD connectors are great. They send data fast for cameras and screens. For telecom or factory use, pick connectors made for those jobs.

Add features like stress protectors or covers.

Small details matter. Stress protectors stop wires from breaking at connection points. Covers keep cables safe from damage or weather. These extras make your cable last longer and work better.

By picking the right materials, connectors, and extras, you can make a strong and useful cable. This step ensures your cable works well and lasts a long time.

Step 4: Check and Finish Your Custom Wire Cable Design

You’ve made your custom wire cable. Before ordering, check everything again. This step makes sure your cable works perfectly.

Check the Details

Reviewing your design is very important. It helps avoid mistakes and ensures the cable works well.

Check size, materials, and if it fits your devices.

First, check the size. Is the length correct? Did you leave extra slack? Next, look at the materials. Are they good for the job? Outdoor cables need weatherproof covers. Car cables need to be strong. Finally, check if it fits your devices. Wrong connectors can make the cable useless.

"Checking details early saves time and money later." – Engineer’s Guide to Custom Cable Design

Make sure it follows safety and industry rules.

Safety is key. Check if your cable meets all rules. For example, car and telecom cables have strict standards. Following these rules makes the cable safe and reliable. If unsure, use guides like Custom Cable Designing Resources to help.

Place Your Order

After checking, you can order your cable. This step makes buying easy and smooth.

Check delivery time and shipping choices.

Before ordering, see when it will arrive. Do you need it fast? Some places offer quick shipping. Also, pick a shipping option that fits your budget. Good shipping keeps your cable safe during delivery.

Save your design for later use.

Don’t forget to save your design. Many tools let you store it for future orders. This helps if you need more cables or want to make changes. Saving your design saves time later.

By reviewing and finishing your design, you make sure your cable is perfect. This step gives you confidence and prepares you for success.

Making custom wire cables lets you solve specific problems easily. By following the steps, your cables will work well and last long. Choosing the right materials and connectors is very important. These choices affect how strong and useful the cable is. This process is not just about making a cable. It’s about fixing issues and facing challenges directly. Start designing your cable now. Create something that fits your needs and lasts. Think differently and turn your ideas into real solutions.

FAQ

What is a custom cable?

A custom cable is made to fit your specific needs. It’s designed for your project, like cars, factories, or outdoor use. If regular cables don’t work for you, custom ones can help. They are built to match your exact requirements and work perfectly.

Why should I choose a custom cable over a standard one?

Regular cables are fine for basic tasks but may not fit special needs. Custom cables let you control everything, like size, material, and connectors. For example, car systems needing High-Speed Data (HSD) work better with custom cables. They ensure the best fit and performance.

How do I start designing a custom cable?

First, figure out what you need the cable to do. Think about where it will be used and what it connects. Then, decide on details like length and flexibility. Use online tools to design your cable step by step. These tools make it easy and quick.

What materials should I consider for my custom cable?

The materials depend on how you’ll use the cable. Outdoor cables need weatherproof covers. Car cables should handle heat and last long. For fast data, like Ethernet, shielding is important. Picking the right materials makes your cable strong and reliable.

Can I add specific connectors to my custom cable?

Yes, you can choose connectors that fit your devices. For example, HSD connectors are great for car systems needing fast data. The right connectors make sure your cable works well and connects easily.

How do I ensure my custom cable meets safety standards?

Check your design carefully to meet safety rules. Use approved materials and parts for your industry, like cars or telecom. Many online tools check for errors and help you follow standards. This keeps your cable safe and dependable.

How long does it take to receive a custom cable?

Delivery time depends on your design and the maker. Some companies offer fast shipping if needed. Before ordering, check how long it will take to arrive. This helps you plan your project better.

Is designing a custom cable expensive?

The price depends on things like materials and features. Custom cables cost more upfront but save money later by working better and lasting longer. Compare prices to find the best deal for your budget.

Can I reorder the same custom cable in the future?

Yes, most tools let you save your design for later. This makes reordering easy and keeps your projects consistent. You can also adjust the design or order more when needed.

What industries benefit most from custom cables?

Custom cables are useful in many fields, like cars, telecom, and factories. They’re also used in medical devices, space projects, and digital systems. Wherever strong and precise cables are needed, custom ones are the best choice.

See Also

Enhancing Automotive Data Flow With Superior Connectors And Cables

Harnessing The Strength Of FAKRA Coaxial Cables

Maximizing The Potential Of FAKRA Coaxial Connectors

Exploring The Flexibility And Advantages Of FAKRA Connectors