Custom Automotive Wiring Harness Trends in High-Speed Data Connectivity

Custom car wiring harnesses are important for today’s vehicles. They help with fast data connections. High-Speed Data (HSD) connectors and cables allow smooth communication. They link systems like ADAS, infotainment, and GPS. These connectors send strong, clear signals at high speeds. This supports the need for new tech in electric and self-driving cars.

Key Takeaways

Custom car wiring harnesses link different systems for smooth power and signals.

Fast data connectors help parts talk quickly, boosting safety and fun features.

Future changes include smaller sizes, faster speeds, and better materials for reliability.

Understanding Custom Automotive Wiring Harnesses

Definition and Role in Automotive Systems

Custom car wiring harnesses are the heart of your car's electrical system. They link different parts, making sure power and signals move smoothly. Without them, your car's electrical parts wouldn’t work. These harnesses aren’t the same for every car. They are made to fit specific needs, which makes them important for today’s cars.

Custom wiring harnesses have three main parts: wires, connectors, and covers. Each part helps send power and signals where needed. Together, these parts make sure your car works well and stays reliable.

Made to match specific car needs.

Include wires, connectors, and protective covers.

Help send power and signals properly.

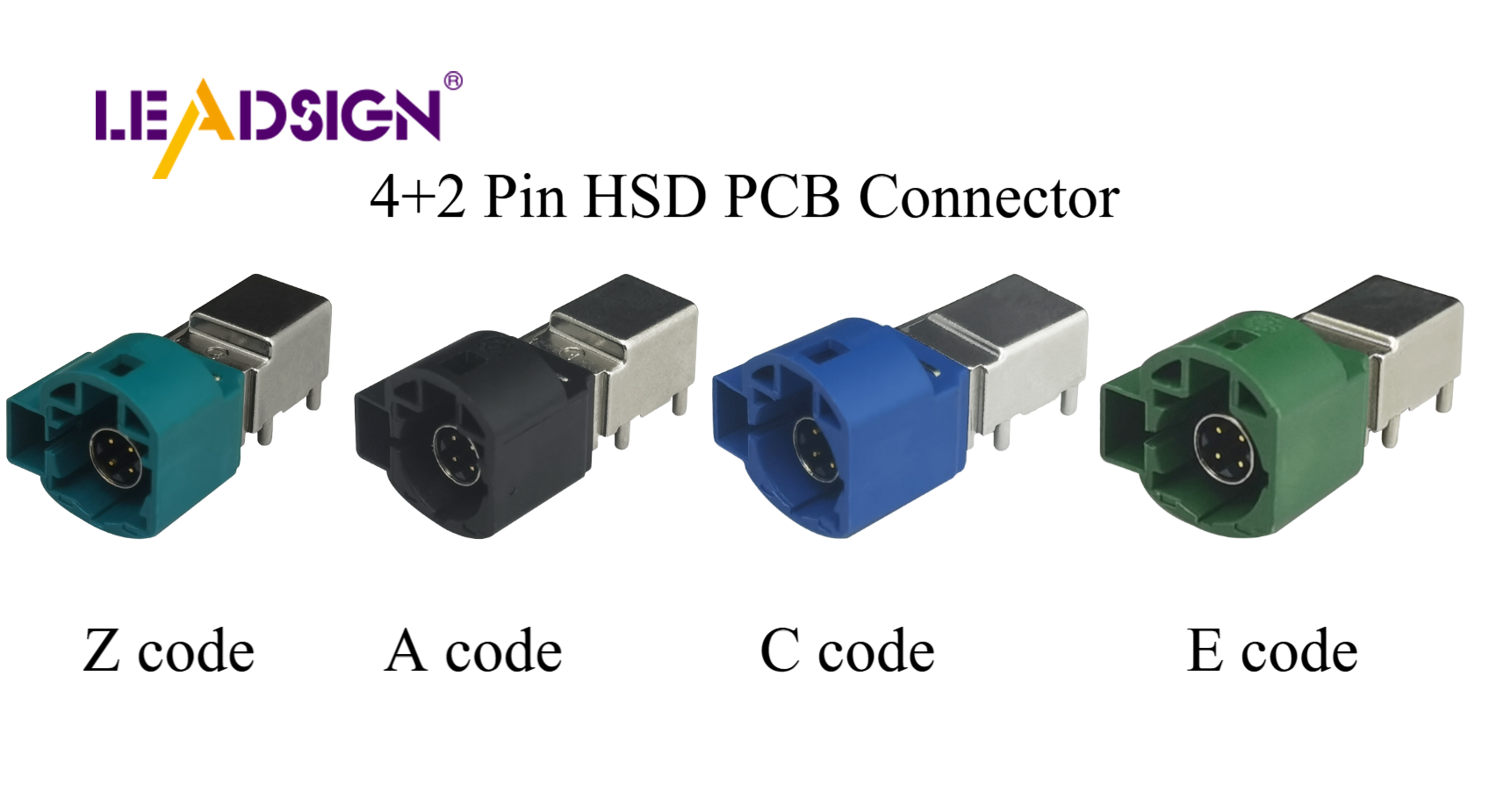

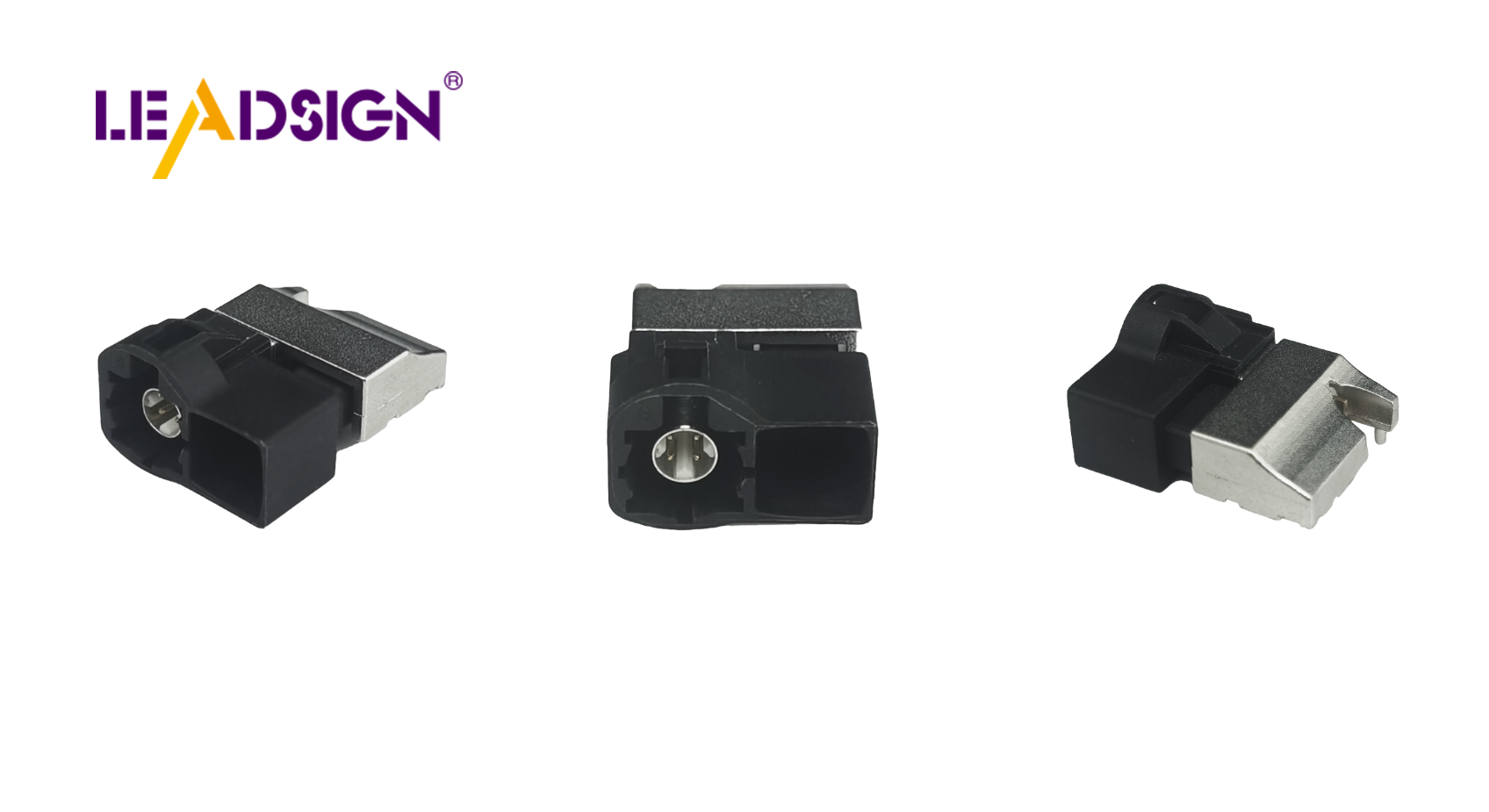

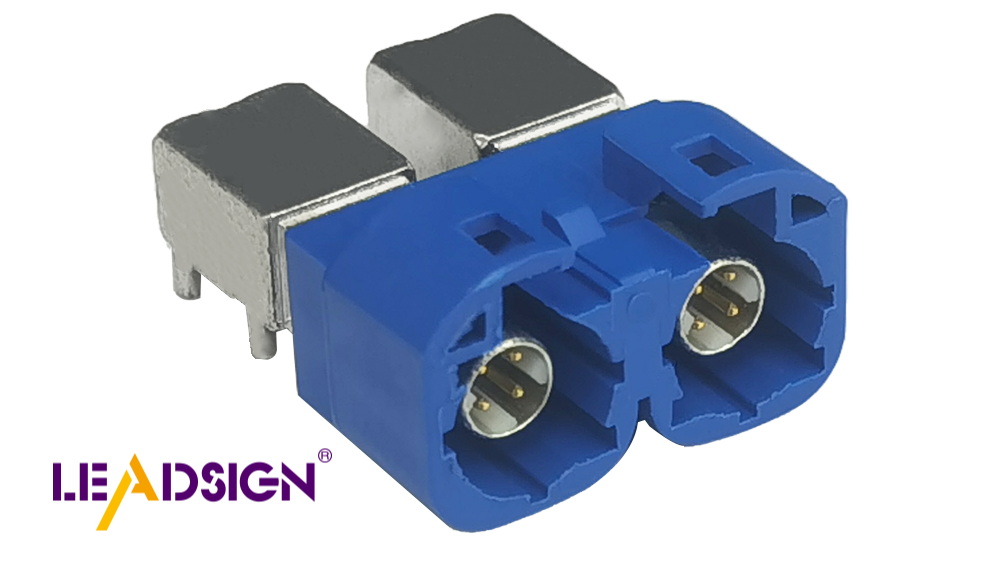

Key Features of High-Speed Data (HSD) Connectors

High-speed data (HSD) connectors and cables are very important for modern cars. They handle fast data, making communication quick and steady. Their special designs make them perfect for car systems.

Part | Material Used | Purpose |

|---|---|---|

Polyamide (PA) or PBT | Strong, heat-resistant, and safe for electricity | |

Seals | Thermoplastic elastomers (TPE) | Flexible and protects from weather |

Insulation | Thermoplastic materials | Keeps signals strong and clear |

Shielding | Metal layers | Blocks unwanted electrical noise |

Locking System | Snap-in or twist locks | Stays secure even with car vibrations |

These features make them strong, reliable, and great for advanced car systems.

Applications of High-Speed Data Connectors in Modern Vehicles

High-speed data connectors improve how your car works. They help with safety systems, entertainment, and electric car functions. These connectors make sure data moves quickly and smoothly.

Safety systems like cruise control and lane warnings use these connectors.

Entertainment systems need them for videos and maps.

Electric cars rely on them for battery and engine control.

Self-driving cars use them to process sensor and camera data.

Using high-speed data (HSD) connectors and cables makes your car faster and more dependable.

Latest Trends in High-Speed Data Connectivity

Smaller and Smarter Designs

Car wiring harnesses are getting smaller and better. Engineers now make compact designs to fit tight spaces. These designs still work well and stay strong. New materials and ideas keep signals clear and durable. Lightweight materials are also important. They help cars use less fuel and perform better. Flexible harnesses and modular designs are becoming popular. These include smart connectors that add more features and flexibility.

Faster Data Speeds and More Bandwidth

Modern cars need faster data speeds for advanced systems. Cameras, sensors, and entertainment systems depend on quick data transfer. For example, cameras need speeds from 500 to 3500 Mbps. Radar systems require up to 5 Mbps. Wiring harnesses now use tech that handles these fast speeds. This helps car parts communicate better, making cars safer and easier to use.

Sensor | Bit rate/sensor |

|---|---|

Camera | 500-3500 Mbps |

Lidar | 20-100 Mbps |

Radar | 0.1-5 Mbps |

Ultrasound | 0.01 Mbps |

Stronger and Weather-Proof Materials

Wiring harnesses must survive tough conditions. Special materials protect them from heat, water, and rust. For example, XLPE and PVDF resist moisture and salt damage. Silicone or polyurethane covers stop scratches and heat damage. These materials keep the harness working well, even in bad weather.

Heat-resistant materials stop cracking.

Insulation keeps out water and rust.

Covers protect from heat and scratches.

Using Advanced Protocols (e.g., USB, Ethernet, LVDS)

New protocols like USB, Ethernet, and LVDS are now used in cars. Ethernet has improved to work well in vehicles. It supports updates and diagnostics with speeds from 100 Mbps to 10 Gbps. High-speed cables and optical fibers replace old wires. These upgrades allow fast data transfer and better communication between car systems, keeping cars connected and efficient.

Today’s wiring harnesses are key to fast data in cars. They mix small designs, quick speeds, and new protocols to meet modern car needs.

Challenges in Designing Wiring Harnesses

Technical Barriers and Compatibility Issues

Making wiring harnesses for fast data has many challenges. Slow data speeds can hurt how systems like ADAS and infotainment work. Adding more electronics to cars makes wiring harder to design and fix. Some cars have up to 5 kilometers of wires, which increases mistakes. Electric cars with high-voltage systems add more problems. These systems can get too hot or damage insulation, causing safety risks.

Slow data speeds lower system performance.

Complex wiring is harder to design and repair.

High-voltage systems may overheat or damage insulation.

Environmental and Durability Considerations

Wiring harnesses must handle tough conditions. They need materials that resist heat, water, and rust. Hot weather can crack wires, and moisture can cause rust. Insulation must block electrical noise and protect from damage. Without these protections, the harness might fail, especially in electric and self-driving cars.

Financial and R&D Investment Challenges

Creating fast wiring harnesses costs a lot of money. Prices for materials are going up, making production more expensive. Advanced systems like ADAS need harder designs, which require more machines. Chip shortages also slow down making these harnesses. Companies must manage these costs while meeting the demand for better car systems.

Material prices are increasing.

Harder designs need more machines.

Chip shortages delay production.

Long Validation Periods and Industry Standards

Following industry rules takes a long time. Safety rules, like those in the European Union, need advanced tech. Groups like IPC set strict rules for quality and compatibility. These rules make sure harnesses are safe and reliable but take time to meet. This slows down new harness designs.

Designing wiring harnesses means solving technical, environmental, and money problems. Following rules ensures safety but takes time and care.

Future Developments and Market Trends

Faster Speeds and Clearer Signals

The future of car wiring harnesses focuses on faster speeds. Systems will handle more data with fewer problems. New materials and better shielding keep signals clear. For example, high-speed HDMI and digital cables now support faster data. These improvements make safety and entertainment systems work better. Cars will be safer and more efficient.

Mini-FAKRA and HSD+ Standards

Mini-FAKRA and HSD+ are changing car connectors. Mini-FAKRA saves space and supports speeds up to 28Gbps. It works well for high-resolution cameras and advanced systems. HSD+ improves data transfer for safety and entertainment systems. These updates make harnesses smaller and lighter. This lowers costs and boosts car performance.

Smarter Cars and Electric Vehicles

Smarter cars and electric vehicles need better wiring harnesses. These harnesses power safety features like emergency brakes and airbags. Electric cars need twice as much wiring as regular cars. This increases the need for high-speed cables. Modular designs are also becoming popular. They make production faster and easier. As tech grows, wiring systems will get smarter.

Market Growth and Opportunities

The wiring harness market will grow from $50.6 billion in 2023 to $75.6 billion by 2033. This is because of more electric cars and advanced safety systems. Manufacturers have big chances in this growing market. Custom wiring is in demand as carmakers want unique designs. More electric cars and V2X communication create new needs. Markets in Asia-Pacific and Latin America also offer growth opportunities.

Custom wiring harnesses are key for fast data in cars. They help share power, send signals, and block interference. Challenges include keeping costs low and handling supply chain issues. Future designs will be smarter, lighter, and follow new standards. Staying informed about changes in the industry is very important.

FAQ

What is a high-speed connector, and why is it important in vehicles?

A high-speed connector helps car parts share data quickly. It connects things like cameras, sensors, and screens. This makes cars work better and more reliably.

How does an HSD cable differ from regular cables?

HSD cables move data fast without much interference. They work with modern systems like USB and Ethernet. This makes them perfect for today’s advanced cars.

What factors influence the market growth for high-speed connectors?

The market grows because of more electric cars and smart tech. Custom designs and faster solutions also give manufacturers new chances.

See Also

Boosting Automotive Data Flow With High-Speed Connectors

Improving Data Transfer in Vehicles With Advanced Connectors

Benefits of Rapid Data Transfer in Automotive Technologies

Transforming Vehicle Connectivity With HFM Connector Benefits

Key Benefits of FAKRA-Mini Connectors for Automotive Applications