Custom wire cables: Benefits and drawbacks explained

Custom wire cables provide you with solutions tailored to meet the unique demands of industrial applications. These cables enhance performance by optimizing electrical properties and ensuring reliability in challenging environments. Their durability reduces the need for frequent replacements, saving you time and maintenance costs. By working with experts, you can achieve compliance with safety standards, minimizing risks like electrical hazards or equipment failures. Additionally, custom designs allow you to integrate multiple functionalities into a single cable, simplifying installation and improving efficiency. These advantages make custom wire cables a strategic choice for specialized needs.

Key Takeaways

Custom wire cables are tailored to meet specific industrial needs, optimizing performance and reliability in challenging environments.

Investing in custom cables can lead to long-term cost savings by reducing the frequency of replacements and minimizing malfunctions.

While custom cables offer enhanced durability, they often come with higher initial costs and longer lead times compared to standard options.

Careful planning and clear communication with manufacturers can help mitigate delays in the production of custom cables.

Custom designs allow for the integration of multiple functionalities into a single cable, simplifying installation and improving efficiency.

Evaluate your project's complexity, budget, and timeline to determine whether custom or standard cables are the best fit for your needs.

Custom cables can be designed to meet safety and compliance standards, reducing risks associated with electrical hazards.

Benefits of Custom Wire Cables

Tailored Performance and Efficiency

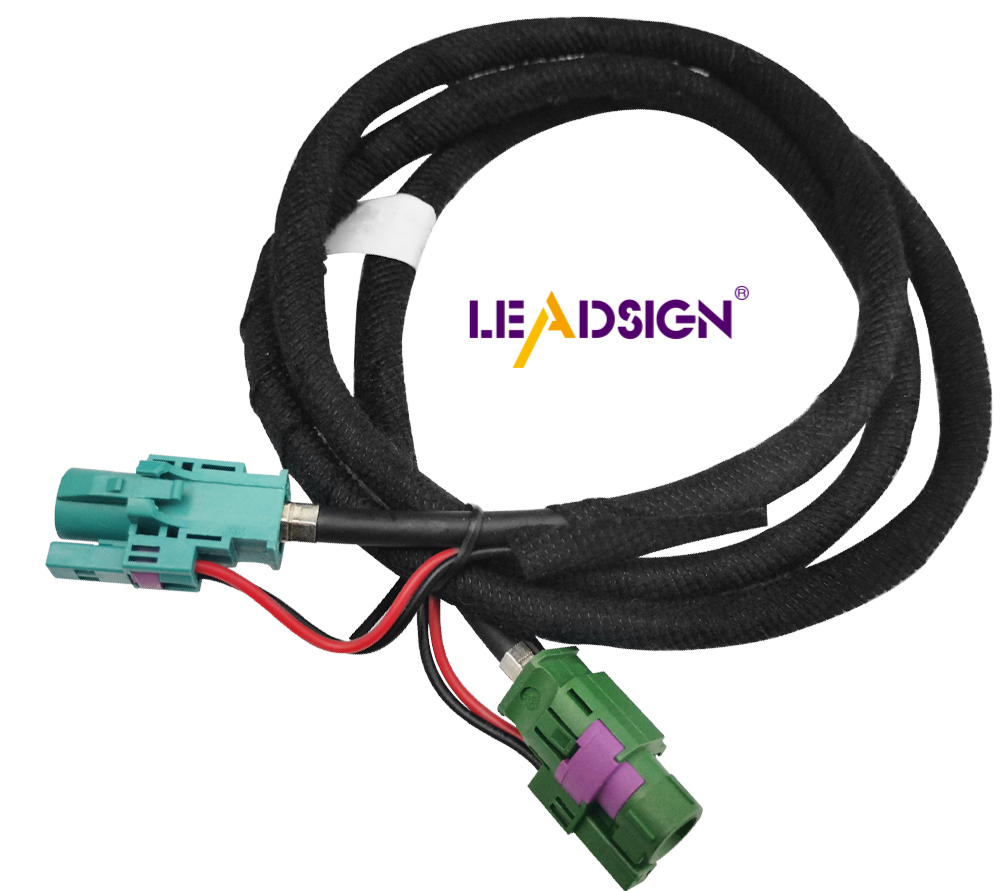

Custom wire cables provide solutions designed to meet your specific needs. Unlike standard cables, these cables allow you to optimize cable performance by addressing unique requirements such as connectivity, speed, or environmental conditions. For example, you can integrate multiple functionalities into a single cable, reducing the need for multiple connections. This customization ensures that your cables perform efficiently in demanding industrial applications. Additionally, custom designs eliminate unnecessary features, which helps you focus on the properties that matter most to your operations.

Enhanced Durability and Reliability

Custom wire cables are built to withstand harsh environments and rigorous use. By selecting materials and designs suited to your application, you can ensure that your cables last longer and perform reliably. For instance, multiconductor cables can be customized to handle high temperatures, moisture, or mechanical stress, making them ideal for challenging conditions. This durability reduces the frequency of replacements and repairs, saving you time and resources. Reliable cables also minimize the risk of system failures, ensuring smooth operations in critical industrial settings.

Long-term Cost Savings

Although custom wire cables may require a higher initial investment, they offer significant cost savings over time. Their enhanced durability means fewer replacements, while their tailored design reduces the likelihood of malfunctions. Multiconductor cables, for example, can combine several functions into one assembly, simplifying installation and lowering labor costs. By investing in cables that meet your exact needs, you avoid the hidden costs associated with using standard cables that may not perform optimally. Over the long term, this strategic choice helps you achieve better value for your money.

Drawbacks of Custom Wire Cables

Higher Initial Costs

Custom wire cables often require a significant upfront investment. The design and manufacturing processes involve specialized materials, advanced engineering, and precise customization. These factors increase the initial costs compared to standard cables. For example, multiconductor cables designed for specific industrial applications may include unique features like enhanced insulation or additional shielding. While these features improve performance, they also contribute to higher production expenses. If your project has a tight budget, this initial cost can pose a challenge. However, it is essential to weigh these costs against the long-term benefits, such as reduced maintenance and improved efficiency.

Longer Lead Times

The production of custom wire cables takes more time than standard cables. Manufacturers need to design, prototype, and test the cables to ensure they meet your exact requirements. This process can delay project timelines, especially if you need large quantities or complex designs. For instance, multiconductor cables with intricate configurations may require additional testing to guarantee reliability. Poor planning or inadequate project management can further extend lead times, leading to missed deadlines. To avoid delays, you should plan ahead and communicate your needs clearly with the manufacturer.

Limited Flexibility for Future Changes

Custom wire cables are tailored to meet specific requirements, which can limit their adaptability to future changes. If your system evolves or your application needs shift, the custom cables may no longer fit the new specifications. For example, multiconductor cables designed for one purpose might not support additional functionalities later. This lack of flexibility can result in additional costs if you need to redesign or replace the cables. To minimize this risk, you should carefully assess your long-term needs before committing to a custom solution.

When to Choose Custom Cable Assembly

Specific Use Cases Where Custom Cable Assembly Excels

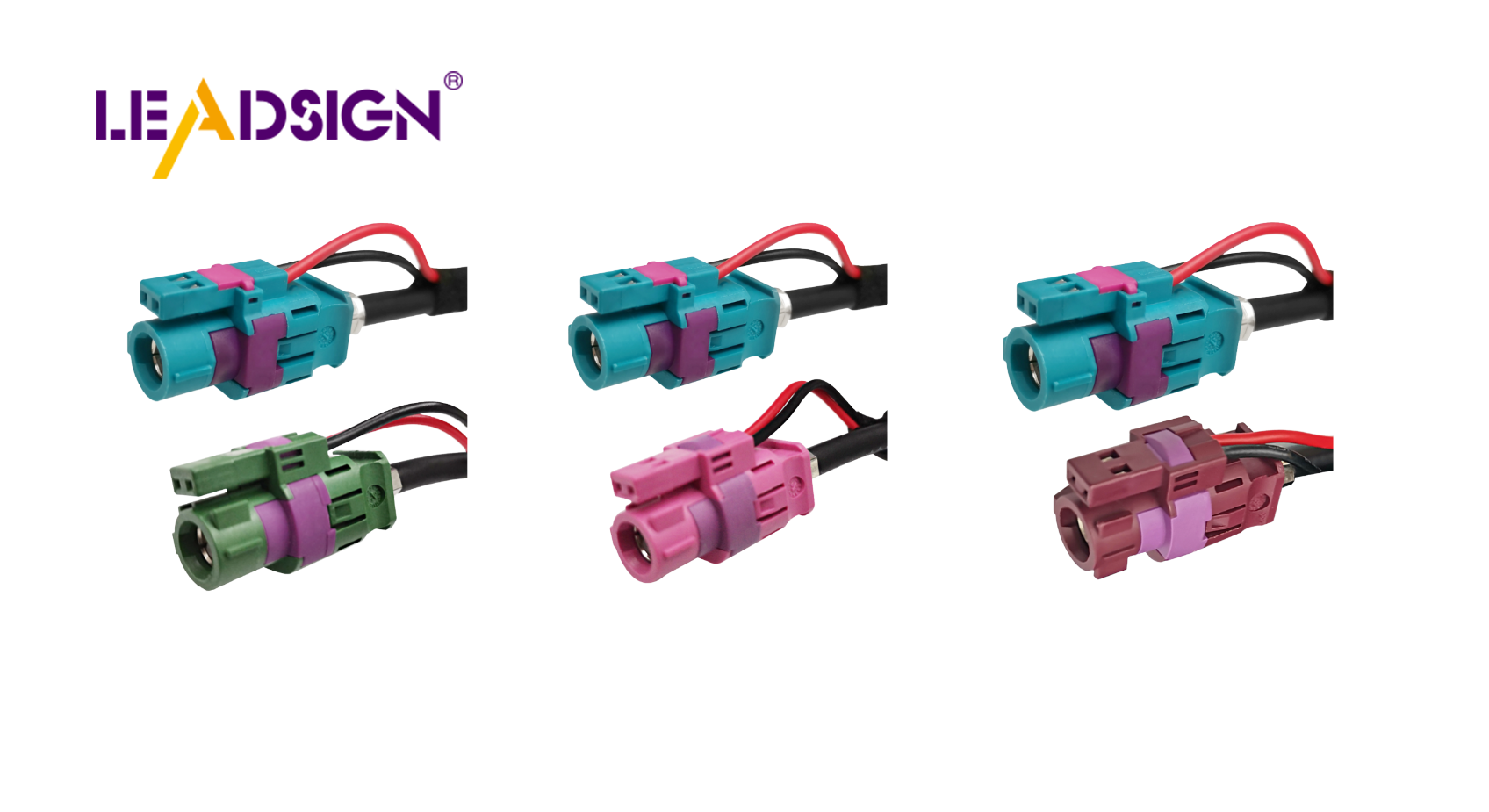

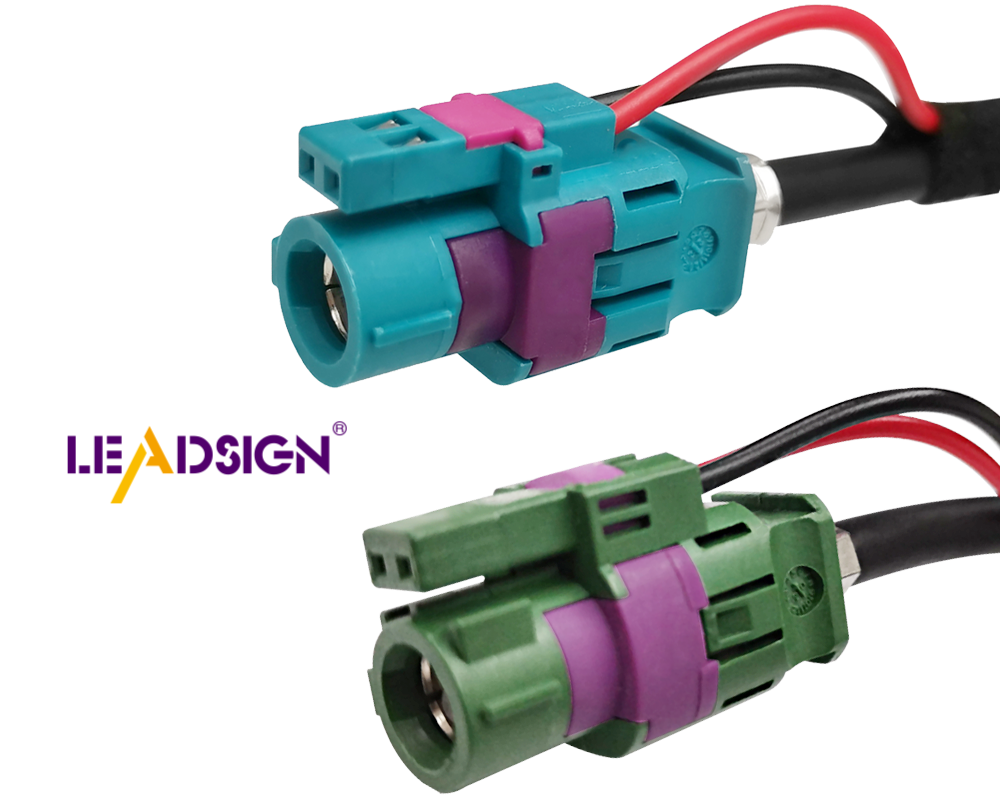

Custom cable assembly is the ideal choice when your project demands precision and unique specifications. For example, industries like automotive electronics or telecommunications often require cables that can handle high-speed data transmission or withstand extreme environmental conditions. A custom cable assembly allows you to integrate multiple functionalities into a single solution, reducing clutter and improving efficiency. This is particularly useful in applications where space is limited, such as in compact industrial machinery or advanced infotainment systems.

"Studying examples of successful custom cable prototyping reveals how tailored designs can overcome challenges like replacing unavailable connectors without compromising functionality." - Industry Expert

Custom solutions also excel in scenarios where standard cables fail to meet safety or performance standards. For instance, if your application involves high temperatures, moisture, or mechanical stress, a custom cable assembly can be designed with materials and features that ensure durability and reliability. Additionally, prototyping and testing during the design phase help you achieve optimal performance while minimizing risks like malfunctions or system failures.

Scenarios Where Standard Cables Are Sufficient

Off-the-shelf cable assembly works well for projects with general requirements and tight timelines. These cables are pre-designed and readily available, making them a cost-effective option for applications that do not require specialized features. For example, if you need basic connectivity for standard devices like USBs or Ethernet networks, off-the-shelf cable assembly provides a quick and reliable solution.

Standard cables are also suitable for projects with flexible budgets or short-term needs. Since they do not involve the design and manufacturing processes of custom cable assembly, they save you time and upfront costs. However, it is essential to evaluate whether these cables meet your long-term requirements. While they may suffice for simple applications, they might lack the durability or performance needed for demanding industrial environments.

By understanding the strengths of both custom cable assembly and off-the-shelf cable assembly, you can make informed decisions based on your specific needs. Carefully assess factors like budget, timeline, and application complexity to determine the best fit for your project.

Custom wire cables and custom cable assembly solutions offer unmatched advantages for specialized industrial applications. They enhance performance, improve durability, and provide long-term cost savings by addressing your specific needs. These tailored solutions ensure efficient data transmission and operational reliability, making them a strategic choice for demanding environments. However, higher initial costs and longer lead times may not suit every project. Off-the-shelf cable assembly remains a practical option for general requirements and tight timelines. By evaluating your budget, timeline, and application complexity, you can determine the best fit for your project and maximize efficiency.

FAQ

Is it better to buy a standard cable or order a custom cable?

The choice depends on your specific needs. Standard cables work well for general applications and tight timelines. They are readily available and cost-effective. Custom cables, on the other hand, offer tailored solutions for unique requirements. If your project demands precision, durability, or advanced functionality, custom cables provide better value. You can even modify off-the-shelf products to create semi-custom solutions. Evaluate your project’s complexity, budget, and timeline to decide which option suits you best.

How long does it take to manufacture custom wire cables?

Custom wire cables typically require more time than standard cables. The process involves designing, prototyping, and testing to meet your exact specifications. Depending on the complexity of the design and the quantity needed, lead times can range from a few weeks to several months. To avoid delays, communicate your requirements clearly and plan your project timeline accordingly.

Are custom wire cables more expensive than standard cables?

Yes, custom wire cables usually have higher upfront costs. The design and manufacturing processes involve specialized materials and engineering. However, they often save money in the long run. Their durability reduces replacements, and their tailored design minimizes malfunctions. Over time, these benefits offset the initial investment, making them a cost-effective choice for demanding applications.

Can custom cables handle extreme environmental conditions?

Absolutely. Custom cables can be designed to withstand harsh environments. For example, they can include features like enhanced insulation, moisture resistance, or high-temperature tolerance. These properties make them ideal for industries like automotive electronics, telecommunications, and industrial automation. If your application involves challenging conditions, custom cables ensure reliable performance.

What industries benefit most from custom wire cables?

Industries with specialized needs benefit the most. Automotive electronics use custom cables for high-speed data transmission in infotainment systems and cameras. Telecommunications rely on them for radio base stations and symmetrical networks. Industrial automation, aerospace, and medical equipment also depend on custom cables for precision and reliability. If your industry requires advanced functionality or durability, custom cables are an excellent choice.

Can I integrate multiple functionalities into a single custom cable?

Yes, custom cables allow you to combine multiple functionalities into one assembly. For instance, multiconductor cables can handle power, data, and signal transmission simultaneously. This integration reduces clutter, simplifies installation, and improves efficiency. It’s especially useful in compact spaces or complex systems where multiple cables would be impractical.

What happens if my system requirements change after ordering custom cables?

Custom cables are designed for specific applications, so they may not adapt well to future changes. If your system evolves, you might need to redesign or replace the cables. To minimize this risk, carefully assess your long-term needs before committing to a custom solution. Discuss potential future requirements with your manufacturer during the design phase.

Do custom cables meet safety and compliance standards?

Yes, custom cables can be designed to meet industry-specific safety and compliance standards. Manufacturers work with you to ensure the cables adhere to regulations like UL, RoHS, or ISO certifications. This reduces risks like electrical hazards or equipment failures. Always confirm that your manufacturer has experience with the required standards for your application.

How do I start the process of ordering custom wire cables?

Start by identifying your project’s specific requirements. Consider factors like functionality, environmental conditions, and budget. Share these details with a reputable manufacturer. They will guide you through the design, prototyping, and production phases. Clear communication ensures the final product meets your expectations.

Can I modify an existing cable instead of designing one from scratch?

Yes, modifying an off-the-shelf cable is a viable option. This approach combines the benefits of standard and custom cables. You can add or remove features to meet your needs without starting from scratch. It’s a cost-effective and time-saving solution for projects with moderate customization requirements.

See Also

Enhancing Automotive Data Flow With Superior Connectors And Cables

Discovering The Flexibility And Advantages Of FAKRA Connectors

Understanding The Advantages Of Fakra Connectors In Vehicles