Custom Wire and Cable Solutions for Vehicle Cable Applications

Vehicle cables are very important in today’s cars. They help cars work well, stay safe, and be reliable. These cables power parts and send data in the car. They are the main part of the car’s electrical system. Picking the right wires helps the car work its best. Custom cables are made to fit special needs. They are designed to last longer and work better. As more electric and smart cars are made, good cables are needed even more.

Key Takeaways

Custom vehicle cables are essential for optimizing your car's electrical system, enhancing safety, performance, and efficiency.

Understanding different types of automotive cables—like primary wires, battery cables, and shielded cables—helps ensure reliable vehicle operation.

Choosing the right insulation material, such as PVC for low-power applications and XLPE for high-heat areas, is crucial for wire longevity and safety.

Selecting the appropriate conductor material (copper for strength and aluminum for weight savings) can significantly impact your vehicle's performance.

Adhering to industry standards (ISO, SAE, UL) guarantees that your automotive cables are safe, durable, and effective in various conditions.

Custom cables can simplify installation by combining multiple circuits into one, reducing clutter and improving organization in your vehicle's wiring.

Regularly consulting with experts can help you choose and design the best cables tailored to your vehicle's specific needs.

Overview of Types of Automotive Cables

Knowing about different automotive cables helps your car work well. Each cable type has a job to keep your car reliable.

Primary Wires

Automotive primary wire is used in many car systems. It works with low voltage, powering lights, dashboards, and other simple parts. This wire bends easily, fitting into tight spaces in cars. Its cover, made from PVC or XLPE, keeps it strong and safe from heat or chemicals. This wire is key for steady performance in all conditions.

Battery Cables

A battery cable connects the battery to the car’s starter and systems. It carries strong currents to start the engine and power parts. These cables are tough, with covers that handle rough conditions. When choosing one, check automotive battery cable specifications like strength and material. Good battery cables keep power flowing and prevent problems.

Shielded Cables

Shielded cables stop interference from affecting car electronics. They are important for systems like GPS, radios, and safety features. A shield, often copper or aluminum, blocks outside noise. Using these cables ensures clear signals, helping your car’s systems work better.

Grounding Wires

Grounding wires are important for keeping your car safe. They let electricity flow back to the battery or car frame. This stops overloads and helps the car work properly. Without grounding, parts might stop working or break.

These wires are often made of strong copper, which conducts electricity well. Their outer layer protects them from water and heat. Grounding wires are used in headlights, sensors, and other parts needing steady power. Good grounding wires keep your car running safely and smoothly.

Coaxial Cables

Coaxial cables send signals in cars without much interference. They are needed for modern systems like GPS and radios. These cables have layers: a center wire, insulation, shielding, and an outer cover. This design blocks interference and keeps signals clear.

You’ll see coaxial cables in GPS, antennas, and car communication systems. They are strong and work well in tough conditions. When picking coaxial cables, check their strength and signal quality. Good coaxial cables improve your car’s entertainment and navigation systems.

Multi-Core Cables

Multi-core cables have many wires inside one cover. They make wiring easier by combining circuits into one cable. Cars use them for wiring harnesses to save space and stay organized.

The outer layer of multi-core cables protects against heat and chemicals. These cables connect sensors, lights, and control parts in cars. Using multi-core cables reduces mess and makes your car’s electrical system more reliable.

Key Features and Uses of Automotive Electrical Wires

Insulation Materials and Their Importance

The cover on a wire is very important. It helps the wire last longer and work well. For car wires, the cover must handle heat, chemicals, and protect the wire. Automotive wire insulation often uses PVC or XLPE materials.

PVC Insulation: PVC is bendable and not expensive. It works in low-power systems like dashboards or lights. But it doesn’t do well in very hot places.

XLPE Insulation: XLPE can handle high heat. It is great for tough automotive applications, like near engines where it gets very hot.

Picking the right cover makes wires last longer. It also stops damage and keeps the car safe from electrical problems.

Conductors: Copper and Aluminum

The metal inside a wire affects how well it carries power. In automotive electrical wire types, copper and aluminum are common choices.

Copper Conductors: Copper carries power well and lasts long. It is used in automotive primary wire and battery cable. It bends easily and doesn’t rust, making it reliable.

Aluminum Conductors: Aluminum is lighter and cheaper than copper. It doesn’t carry power as well but is good for lighter cars, like electric ones.

Choose the metal based on your car’s needs. Copper is best for strong systems, while aluminum is good for lighter designs.

Uses in Modern Cars

New cars use advanced systems for better safety and performance. Different automotive electrical wire types are used for specific jobs:

Infotainment Systems: Multi-core cables link screens, speakers, and controls for smooth use.

Driver-Assistance Systems: Shielded and multi-core cables stop interference, helping sensors work well.

Power Systems: Automotive primary wire and battery cable send power to lights, motors, and controls.

Communication Systems: Coaxial and shielded cables send data for GPS and car communication.

Knowing these uses helps you pick the best wires for your car. This improves how your car works and stays reliable.

Why Custom Vehicle Cables Matter

Custom vehicle cables help your car’s electrical system work better. They are made to fit your car’s special needs, improving safety, performance, and efficiency.

Special Designs for Different Cars

Each car model needs different types of cables. Custom cables meet these needs perfectly. Small cars might need light cables, while trucks need stronger ones. Custom cables fit well in the car, saving space and working efficiently.

Modern cars have advanced systems like GPS and screens. These systems need special wiring. Custom multi-core cables combine many wires into one. This makes wiring easier and keeps everything organized.

You can also pick the best materials for your cables. PVC is good for low-power parts, while XLPE or silicone works in hot areas. Choosing the right materials makes cables last longer and work better.

Better Performance, Safety, and Efficiency

Custom cables make your car perform well. The right wires send power and signals smoothly. For example, primary wires power lights, and shielded cables keep signals clear.

Safety improves with custom cables too. Good grounding wires stop electrical problems. Strong insulation protects wires from heat, water, and chemicals, keeping your car safe.

Custom cables also make cars more efficient. Light materials like aluminum reduce car weight, which helps electric cars. Multi-core cables save space and make installation easier. These features help your car last longer and work better.

Custom cables let you build a system that fits your car. Whether you want better safety, performance, or efficiency, custom designs make your car the best it can be.

Standards and Certifications for Automotive Cables

Knowing about standards for automotive cables helps ensure safety and quality. These rules guide you in picking cables that meet industry needs.

Important Industry Standards (ISO, SAE, UL)

Standards like ISO, SAE, and UL ensure wires are safe and strong. They explain how wires should work in different conditions.

ISO Standards: ISO creates global rules for automotive wire quality. ISO-certified wires handle heat, bend easily, and have good insulation. For example, ISO 6722 sets rules for single-core vehicle cables.

SAE Standards: SAE focuses on rules for car wiring. SAE J1128 explains how low-voltage wires should perform. These rules make sure wires meet modern car needs.

UL Standards: UL checks wires for safety and strength. UL-listed cables pass tests for fire, chemicals, and heat resistance. This certification ensures the cables are dependable.

Using cables that follow these standards keeps your car’s wiring safe and effective.

Testing and Compliance for Safety and Quality

Tests check if wires are good enough before being used in cars. These tests make sure cables meet or exceed the required standards.

Durability Tests: These tests see if wires survive tough conditions like heat, shaking, and chemicals. Wires near engines must handle high heat without breaking.

Electrical Performance Tests: These tests check if wires carry power well. They ensure wires deliver steady electricity to lights, sensors, and other parts.

EMI/RFI Shielding Tests: Shielded wires are tested to block interference from signals. This keeps GPS, radios, and other systems working clearly.

Custom cables have shown their value in real-world use. These examples prove why strict testing is important. When cables pass these tests, they work well and keep cars safe.

Learning about these certifications and tests helps you choose the right wires. This knowledge ensures safety, quality, and long-lasting performance.

How to Choose the Right Automotive Wire Types

Picking the right automotive wire types keeps your car safe and efficient. Each choice affects how well the wires work for their job.

Gauge Size and Current Capacity

The wire's gauge size shows how much current it can carry. Smaller numbers mean thicker wires, which handle more current. Thick wires are used for starters or alternators. Thin wires work for lights or sensors.

Using the wrong size can cause overheating or power loss. Always match the wire size to your system's needs. Rules like SAE J1128 and ISO 6722 help you pick the right size. These rules make sure wires are safe and work well.

Tip: Check your car manual or ask an expert to find the right size.

Insulation and Durability

The wire's cover protects it from heat, chemicals, and damage. Picking the right cover makes wires last longer and work better. Common covers are PVC and XLPE.

PVC Insulation: PVC is bendable and cheap. It works for low-power parts but not in hot areas.

XLPE Insulation: XLPE handles heat well. It’s great for engines and hot spots.

Strong wires resist wear and tear. Wires tested under ISO 6722 or SAE J1127 are tough and safe. These tests prove the wires can handle hard conditions.

Pro Tip: Use heat-resistant wires for areas with extreme conditions.

Flexibility and Ease of Installation

Flexible wires are easier to install, especially in tight spaces. They bend without breaking, making them good for tricky wiring setups. Multi-core cables combine many wires into one, saving space and reducing mess.

Easy installation depends on the wire's design and connectors. Wires meeting SAE and ISO standards are often simple to use. Flexible wires save time and lower the chance of damage during setup.

Remember: Flexible wires are key for modern cars. They make installation faster and improve reliability.

Knowing about car cables and their uses is important. Each cable helps power parts and keeps the car running well. Custom cables make cars work better by fitting special needs. They last longer and work more efficiently. Picking the right cables ensures your car stays reliable. For help, ask experts to choose and design cables for your car.

FAQ

Why are custom vehicle cables better than regular ones?

Custom cables are made to fit your car’s needs. They work better and last longer than regular cables. These cables follow strict rules for safety, like insulation and grounding. They also support new tech like GPS and smart car features, keeping your car modern.

Why is insulation important for car wires?

Insulation keeps wires safe from heat, chemicals, and damage. It helps wires last longer and work well in tough places. PVC is good for low-power parts, while XLPE works near hot engines. Picking the right insulation stops problems and keeps your car safe.

How do custom cables help during car assembly?

Custom cables make car assembly easier by combining wires into one. This saves time and reduces mistakes when setting up. Flexible designs fit into tight spaces, keeping the wiring neat and organized. This makes building cars faster and more efficient.

Can custom cables handle new car technologies?

Yes, custom cables can be changed to fit new tech. They work with systems like smart cars, driver-assist features, and fast data links. This means your car can stay updated with the latest technology.

What do grounding wires do in a car?

Grounding wires safely send electricity back to the battery or frame. They stop overloads and protect parts from breaking. Strong copper grounding wires are key for keeping lights, sensors, and controls working safely.

How do shielded cables stop interference?

Shielded cables block outside signals that can mess up car systems. A special layer, often copper or aluminum, keeps signals clear. These cables are important for GPS, radios, and car communication, ensuring everything works smoothly.

What should you think about when picking car wires?

When choosing wires, focus on three things:

Gauge Size: Make sure the wire is thick enough for the job.

Insulation Material: Use PVC for cool areas and XLPE for hot spots.

Flexibility: Pick wires that bend easily for tight spaces.

These tips help your car’s wires work safely and efficiently.

Are custom cables tested for safety?

Yes, custom cables go through many tests to meet safety rules. Tests check if they can handle heat, shaking, and chemicals. Passing these tests shows the cables are strong, safe, and reliable.

How do multi-core cables help modern cars?

Multi-core cables put many wires into one, saving space. They are great for systems with lots of circuits. The outer cover protects them from heat and chemicals. These cables keep your car’s wiring neat and efficient.

Why follow car wire standards?

Car wire standards, like ISO 6722 and SAE J1128, make sure wires are safe and strong. These rules test how wires handle heat, power, and stress. Using standard wires lowers the chance of problems, keeping your car safe and reliable.

See Also

Maximizing Automotive Data Flow With Innovative Connectors

Boosting Data Transfer: Why Fast Automotive Connectors Matter

Benefits of HFM Connectors for Automotive Applications

Transforming Automotive Connections With HFM Connector Benefits

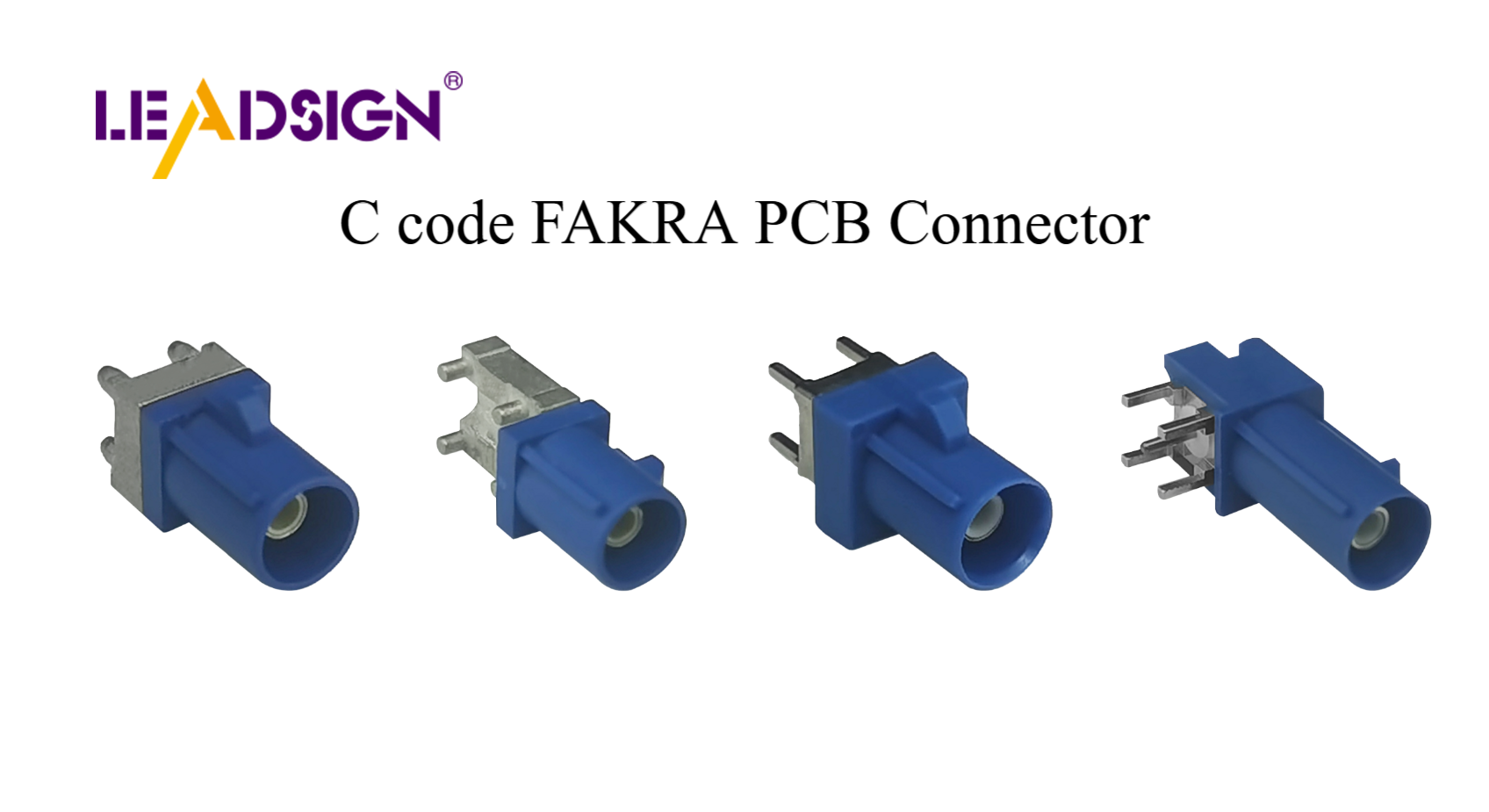

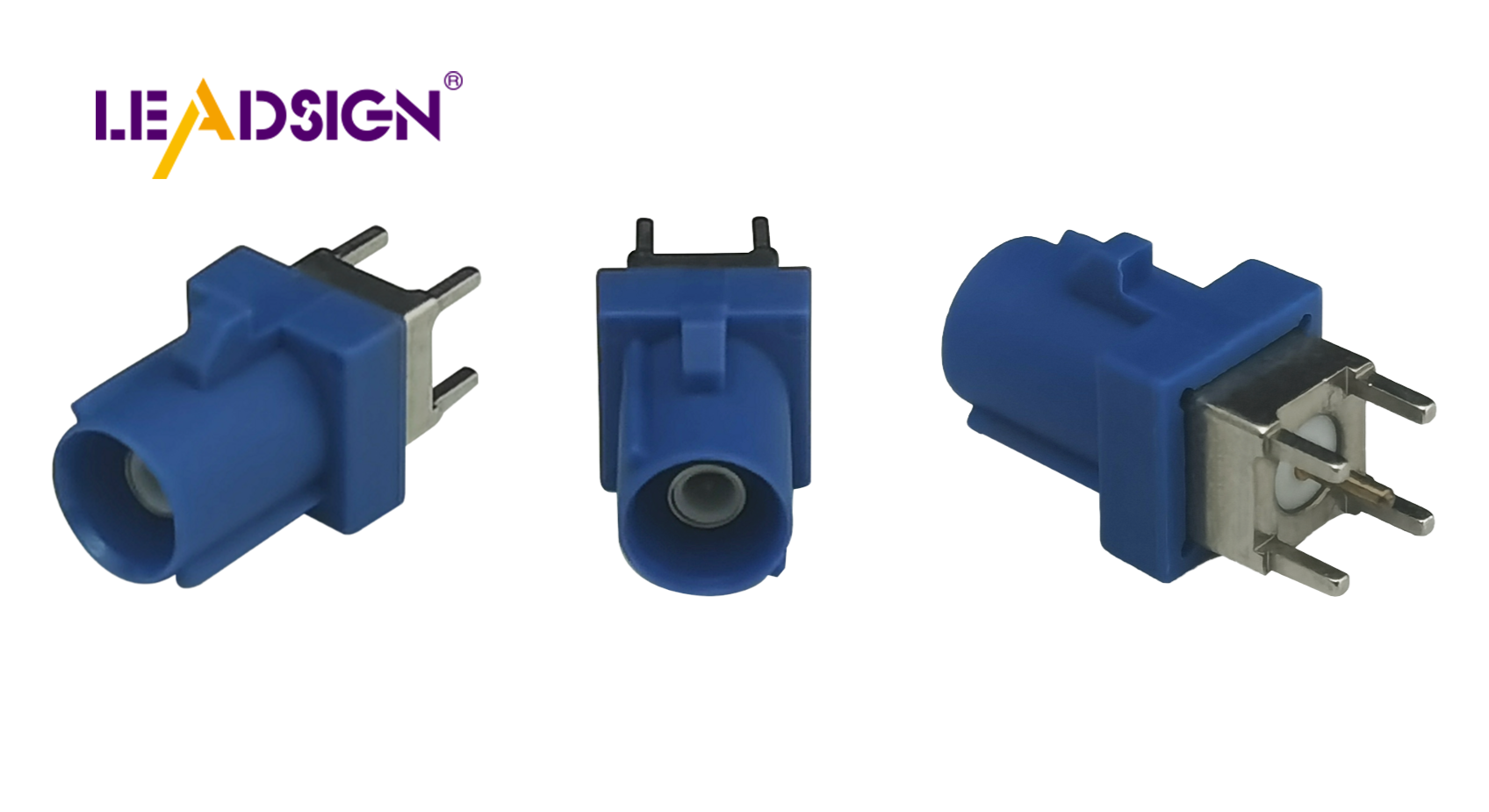

Improving Automotive Data Transfer Using FAKRA PCB Connectors