How Custom Cable Makers Enhance Automotive Ethernet Performance

Custom vehicle cable makers change how car Ethernet systems work. They solve big problems like fast data, strong signals, and tough conditions. By making special cables, they help car systems talk easily. These vehicle cables send data faster, work well in hard conditions, and meet strict rules. Their skills give you better cables for cars, improving how they work. This makes them very important for today’s car technology.

Key Takeaways

Custom cables are essential for modern cars, enabling faster data transfer and improved performance in automotive Ethernet systems.

They are designed to handle high data rates, comparable to CAT-8 cables, ensuring smooth operation of entertainment and safety features.

Special shielding in custom cables minimizes noise interference, leading to clearer signals and more reliable communication between vehicle systems.

Built to withstand harsh automotive conditions, custom cables use durable materials that resist heat, vibration, and chemicals, reducing the need for repairs.

By adhering to industry standards like IEEE 802.3bw, custom cables ensure compatibility and optimal performance within car systems.

Investing in custom cables may have higher upfront costs but results in long-term savings through reduced maintenance and increased reliability.

Choosing custom cables tailored to specific automotive needs enhances the overall functionality and longevity of vehicle systems.

Problems in Car Ethernet Systems

Car Ethernet systems have special problems needing smart fixes. As cars get smarter, they need better ways to share data. Knowing these problems shows why custom cable makers are important.

Faster Data and More Bandwidth

New cars need fast data for things like entertainment, safety, and internet features. These systems need lots of data to work well. Regular cables can’t always keep up, causing slowdowns or failures. Custom cables are made for cars and fix this by handling faster data. For example, they can work as fast as CAT-8 cables, which send data up to 40 Gbps. This makes them great for car systems needing lots of data.

Keeping Signals Clear

Good signals are very important in car Ethernet systems. Noise from car electronics can mess up signals, causing errors. Custom cables solve this with special shields to block noise. They use strong materials and careful designs to keep signals steady. By stopping noise and signal mix-ups, custom cables make car systems more reliable.

Tough Car Conditions

Cars face tough conditions like heat, shaking, water, and chemicals. Regular cables often break in these situations, needing fixes or replacements. Custom cables are made to last in these hard conditions. They use strong materials and smart designs to stay reliable. For example, cables for car tracking or radio signals work well even in bad conditions. This means fewer problems and keeps car systems running longer.

How Custom Cable Makers Improve Vehicle Cable Performance

Custom cable makers help make vehicle cables work better. They use their skills to meet the needs of modern cars. By creating special designs, using strong materials, and following rules, they make cables that improve car systems.

Special Cable Designs for Cars

Custom cable makers create cables just for cars. They think about what cars need, like small spaces, fast data, and strength. These cables solve problems like tight spaces and tricky wiring. For example, custom cables are lighter and work better than regular ones. This helps them fit well in cars and support cool features like self-driving and entertainment systems.

Strong Materials for Tough Conditions

The materials in car cables affect how long they last. Custom cable makers pick strong materials for tough car conditions like heat, shaking, and chemicals. These materials keep signals clear even in hard situations. For example, Ethernet cables for cars handle lots of data and stay strong. This makes car systems last longer and need fewer repairs.

Following Car Ethernet Rules

Car Ethernet rules make sure cables work well together. Custom cable makers follow these rules, like IEEE 802.3bw and IEEE 802.3bp. These rules say how fast data moves and how cables should be made. By following them, custom cables help car systems talk easily. This makes car systems better and ready for new technology.

Benefits of Custom Cable Solutions for Automotive Ethernet

Custom cables help automotive Ethernet systems work better and last longer. They are made to handle the special needs of modern vehicles. This makes them more reliable in different automotive situations.

Better Signal Strength in Vehicle Cables

Custom cables keep signals strong by stopping interruptions. They use special shields to block outside interference. This helps your vehicle cable stay connected, even in tricky automotive setups. Good materials and careful designs also cut down signal loss. This makes your systems work smoothly. With stronger signals, important parts in your automotive systems can talk easily.

Less Noise and Fewer Problems in Automotive Systems

Noise can mess up automotive Ethernet systems, causing mistakes or slowdowns. Custom cables fix this with designs that block bad signals. They use strong shields and smart layouts to stop noise from breaking data flow. By cutting noise, custom cables make sure your vehicle cable works well. This is very helpful for things like safety systems and entertainment, where steady data is key.

Stronger and Longer-Lasting in Tough Conditions

Custom cables are made to handle hard automotive conditions. They use tough materials that resist heat, shaking, water, and chemicals. This makes them great for long-term automotive Ethernet use. They are light but strong, so your vehicle cable stays reliable over time. Picking custom cables means fewer fixes and lower costs, keeping your systems running longer.

Custom cable makers change how car Ethernet systems work. They solve problems by making cables for faster data and strong signals. These cables are tough and last in hard conditions. They help advanced car tech, like safety systems, work better. By following rules, they make sure cables fit and work well. Picking custom cables means better performance and fewer repairs. Their skills are key to improving car technology for today’s needs.

FAQ

What are the benefits of custom Ethernet cables?

Custom Ethernet cables are made to fit your needs. They keep connections steady and improve network performance. These cables are designed for better and more reliable systems.

How do custom cable assemblies help in cars?

Custom cable assemblies are strong and built for tough car conditions. They can handle heat, shaking, and chemicals. This makes them last longer and lowers repair costs in vehicles.

Why pick custom cables instead of regular ones?

Custom cables are flexible and made for specific needs. They fit special lengths or tough environments. Regular cables might not work as well in hard situations.

What should you think about when picking custom cables?

Think about how far the cable needs to go, how fast data moves, and the environment. Custom cables are made to match these needs perfectly.

Can custom cables make car Ethernet signals better?

Yes, custom cables stop noise and keep signals clear. They use good materials and special shields to make communication steady in cars.

Are custom cables worth the cost for cars?

Custom cables cost more at first but save money later. They last longer and need fewer repairs, which lowers overall costs.

How do custom cables survive tough car conditions?

Custom cables are made with strong materials to handle heat, shaking, and chemicals. This makes them perfect for hard car environments.

Do custom cables follow car Ethernet rules?

Yes, custom cables meet strict car Ethernet rules like IEEE 802.3bw. This helps them work well with car systems.

Which industries use custom cables the most?

Industries like cars, planes, and phones use custom cables. These cables handle fast data and tough conditions.

How do custom cables improve new car technology?

Custom cables help with cool car features like entertainment and safety. They send data fast, keep signals strong, and last a long time.

See Also

Maximizing Automotive Data Flow With Innovative Connectors

Boosting Data Transfer: The Role of Fast Automotive Connectors

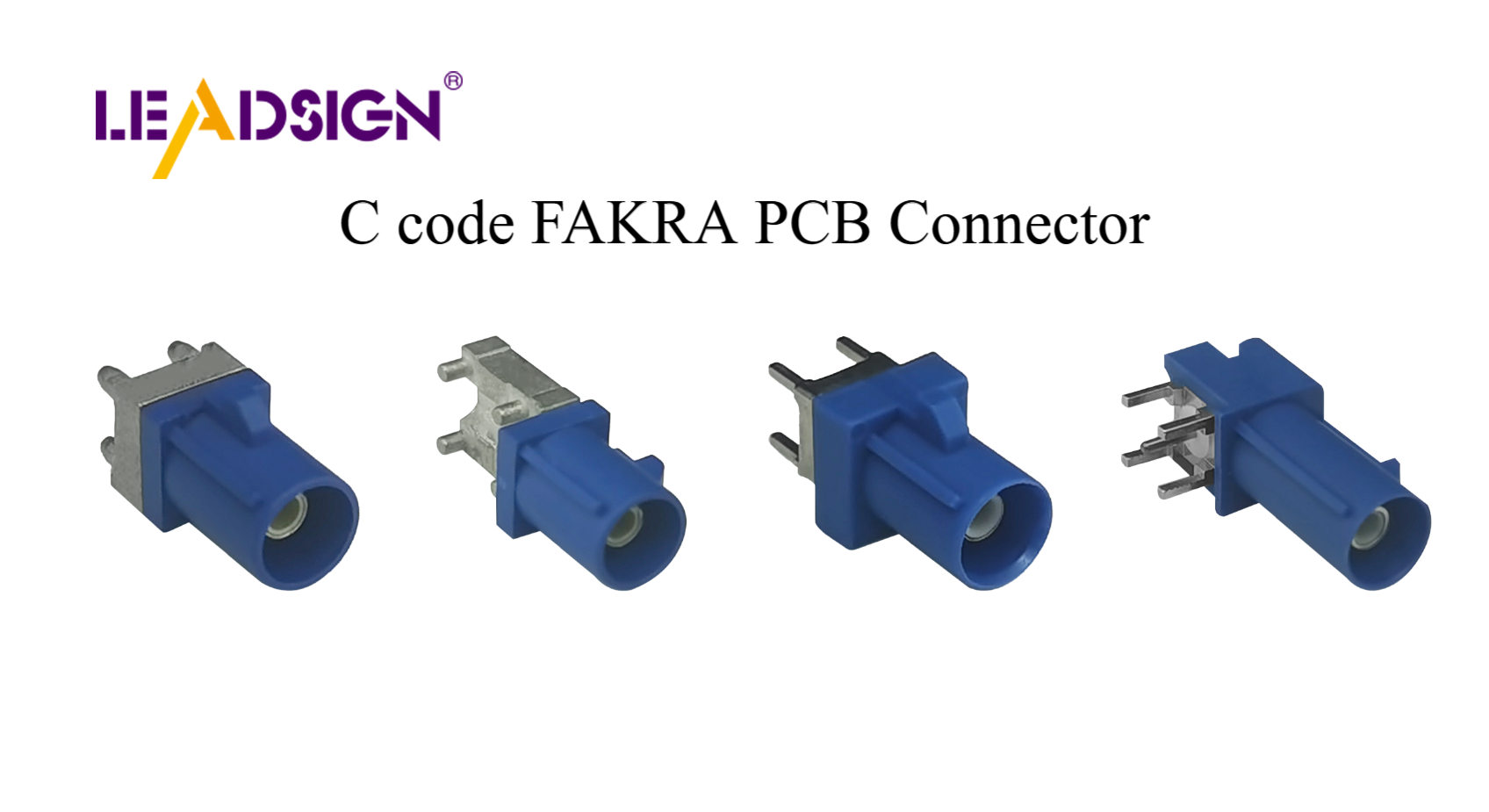

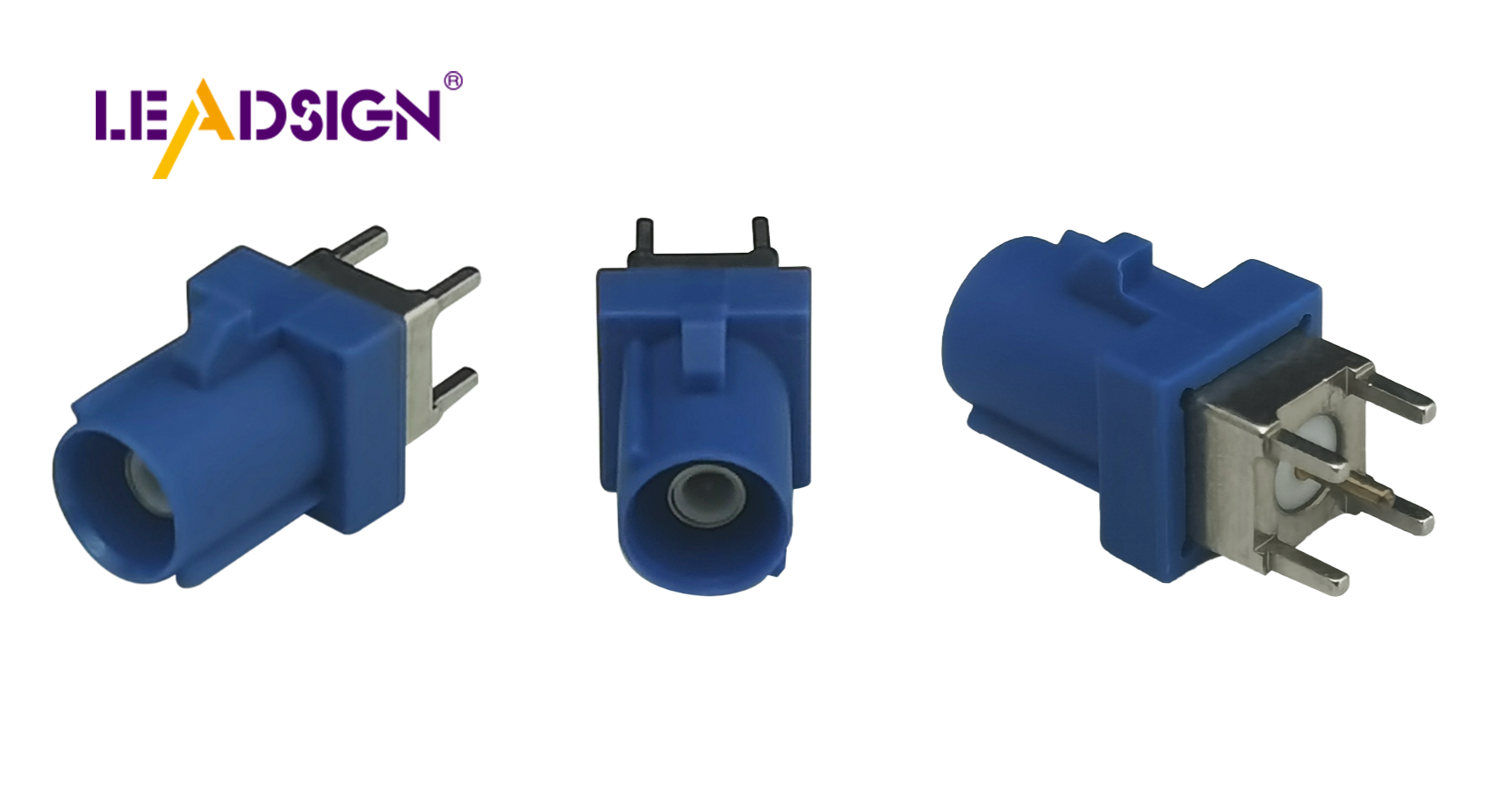

Improving Automotive Data Flow Using FAKRA PCB Connectors