Custom Power Cables and Automotive Wire Connectors Types: A Comparative Analysis

Power cables and wire connectors are very important. They help energy move smoothly in many industries. As technology gets better, more custom power cables are needed. These special cables work better because they meet specific needs. They offer flexibility and efficiency. The worldwide market for these items may reach USD 146.24 billion by 2029. This shows a growth rate of 7.30%. This trend shows how important custom solutions are for industry and cars.

Understanding Custom Power Cables

Custom power cables are important for your electronics. They make sure devices get the right power. These cables fit specific needs in many industries. Let's look at different custom power cables and their pros and cons.

Types of Custom Power Cables

High Voltage Cables

High voltage cables carry lots of electricity far away. You see them in factories where big power is needed. They make sure power gets there safely and well.

Low Voltage Cables

Low voltage cables need less power. They are great for homes and offices. These cables safely power things like lights and small gadgets.

Flexible Cables

Flexible cables bend easily where movement happens a lot. Use them in robots or machines that move often. Their bending keeps them from breaking, making them last long.

Advantages of Custom Power Cables

Tailored Specifications

Custom cables match your exact needs. This means they work perfectly with your gear, giving top performance. You pick the right parts to meet your goals.

Enhanced Performance

With custom cables, you get better performance. They handle certain loads well, cutting failure risks. Trust them for steady power without stops.

Cost Efficiency

Custom cables might cost more first but save money later. Less downtime and fixes mean savings over time. Good quality makes work run smoothly.

Disadvantages of Custom Power Cables

Higher Initial Costs

A downside is higher starting costs for custom cables than regular ones. But their benefits often beat the first price.

Longer Lead Times

Making custom cables takes longer to design and build. Expect waits when ordering these special wires, so plan ahead to get them on time.

Complexity in Design

Designing custom wires can be tricky with many factors like voltage and environment to consider carefully.

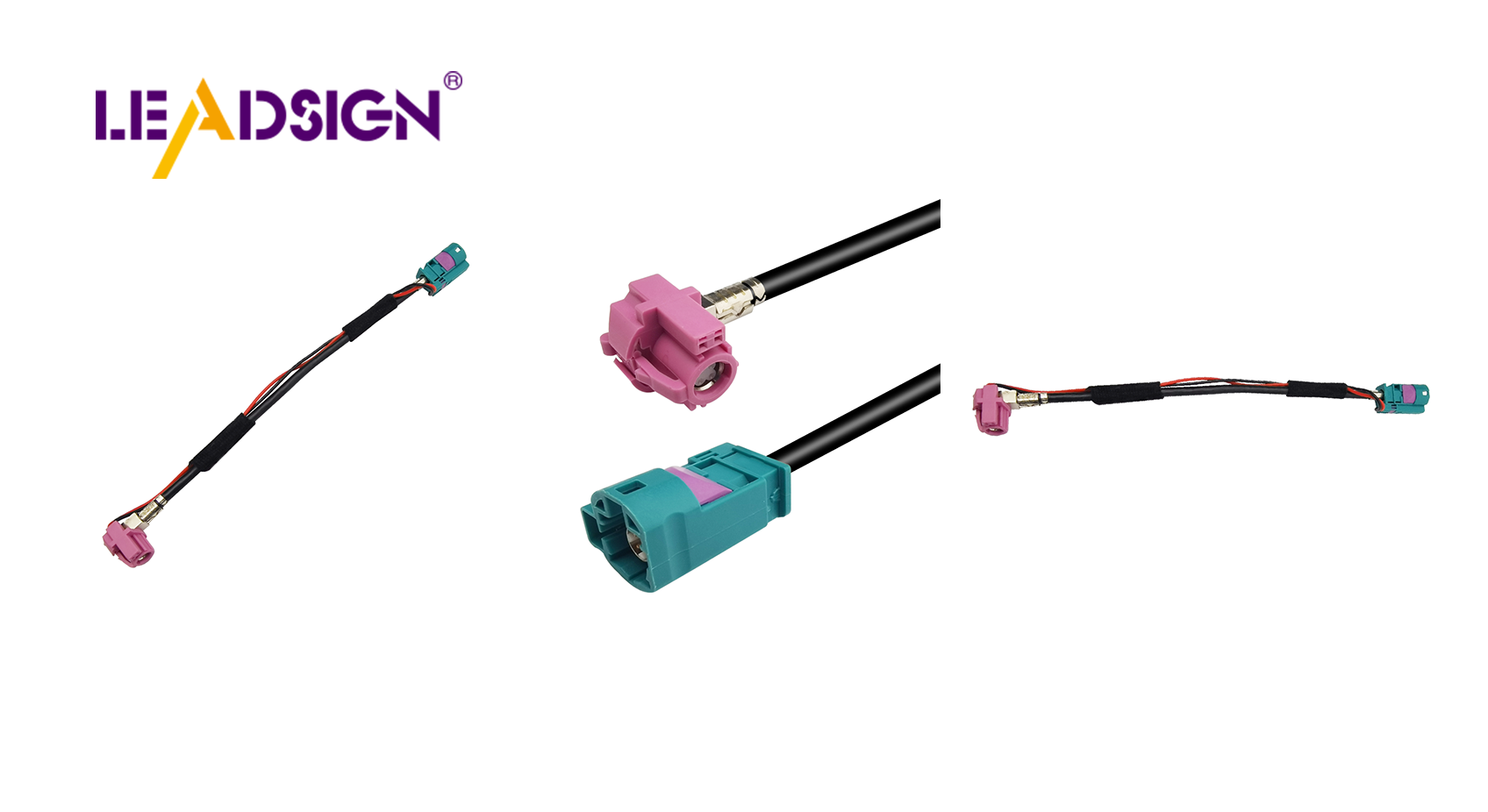

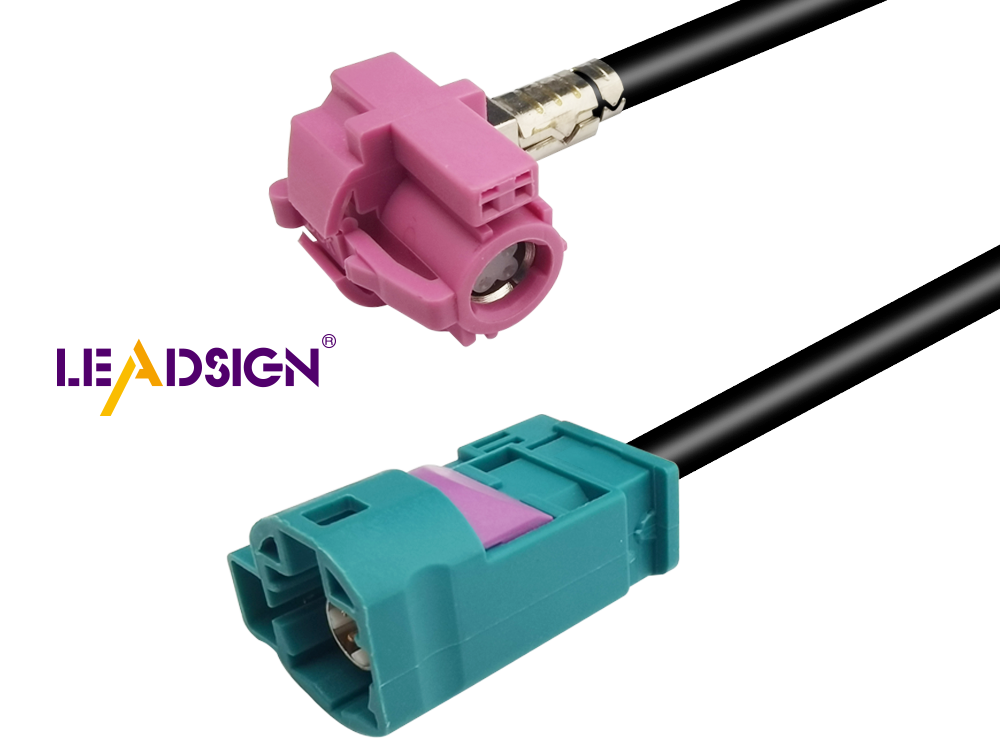

Exploring Automotive Wire Connectors

Automotive wire connectors are very important. They keep electricity flowing in cars. This is needed for car systems to work well. Let's look at different types of automotive wire connectors and their good and bad points.

Types of Automotive Wire Connectors

Butt Connectors

Butt connectors join two wires together. Use them to fix or make wires longer. They hold wires tight by squeezing them together. These are often used in cars because they are simple and work well.

Ring Connectors

Ring connectors have a round end that fits on a bolt or screw. Use them to attach wires to blocks or ground spots. Their shape makes a strong link, great for shaky places like cars.

Spade Connectors

Spade connectors look like forks, making it easy to put on and take off terminals. They help when you need to disconnect often. Their design allows fast setup, so they are liked in car wiring.

Advantages of Automotive Wire Connectors

Ease of Installation

These connectors make putting wires together easy. You can connect quickly without soldering, saving time and lowering mistakes during setup.

Reliability in Connections

They give strong links that last in tough car conditions. Trust them to keep power going even with lots of shaking and temperature changes.

Versatility in Applications

You can use these connectors for many things, from lights to big electronic systems in cars. Their flexibility makes them useful parts in car wiring.

Disadvantages of Automotive Wire Connectors

Potential for Corrosion

One bad thing is they might rust, especially if wet. Make sure they are sealed well to stop rust problems.

Limited Current Capacity

These connectors might not handle big currents well. Pick the right one for your job to avoid getting too hot or breaking down.

Need for Regular Maintenance

Check these connections often for wear or damage so they keep working right.

Comparing Cables and Connectors

Here, we see how power cables and wire connectors compare. This helps us know their performance, costs, and uses.

How They Work

Strength

Custom cables are very strong. They last long in tough places. High voltage ones work well in factories. Wire connectors can rust if wet. Check them often to stop this.

Working Well

Choosing between cables and connectors depends on needs. Custom cables fit special jobs, making them work better. They give good power with less waste. Connectors are easy to set up fast in cars.

Cost Look

Starting Costs

Custom cables cost more at first because they are special-made. But they are worth it if you need exact matches. Wire connectors cost less at the start, good for car use.

Saving Money Later

Custom cables save money over time by working well longer. They cut down fixing time and costs, great for reliable work areas. Wire connectors might need more fixes later.

Where to Use Them

For Factories

In factories, custom cables do great jobs. They handle big power needs well, keeping things running smoothly.

For Cars

Wire connectors are made for cars. They link car parts like lights easily and quickly as needed.

Both have good points and bad points. Pick what fits your needs best: custom cable strength or connector ease.

Custom power cables are made to fit special needs. They work well in factories but cost more at first and take longer to get. Automotive wire connectors are easy to use and last long in cars, but need checking often to stop rust.

Think about what you need when picking between them. Custom cables are strong and work well for tough jobs. Wire connectors are good for quick setups. To learn more, read about electrical engineering and car technology.

See Also

Maximizing Automotive Data Transfer: Cutting-Edge Connectors and Wires

Investigating the Advantages of Fakra Auto Connectors

The Significance of Fakra Connectors in Auto Sector

Improving Data Transfer: The Significance of High-Velocity Auto Connectors