Custom Power Cables Made Easy

Custom power cables are important for smooth electrical work. You can change these cables to fit specific needs. This helps systems in electronics and engineering work better. In car electronics, custom power cables are very helpful. They make sure connections for fast data, like USB and Ethernet, work well. These are important for new cars. Also, bendable power cables are needed for moving devices. They last long and can change shape easily. By knowing why custom power cables matter, you can make your electronic systems work better.

Understanding Custom Power Cables

Custom power cables help electronic systems work well. By knowing their parts, you can make cables fit your needs.

Important Parts and Choices

Choosing Terminals

Picking the right terminals is key. Terminals link cables to devices safely. Choose based on device type and where it’s used. Car electronics need terminals that handle shakes and temperature changes.

Length and Thickness

Cable length and thickness affect how they work. Longer cables might need to be thicker to keep power strong. Thickness means how thick the wire inside is. Thicker wires carry more power, good for big jobs. Measure length and thickness carefully for best results.

Extra Features

Custom cables have extra features for better use. Pick different covers to protect from weather or damage. Covers stop leaks and give strength. You can add shields to block interference too. These choices help make strong, reliable cables for different uses.

Materials and How They Work

When making custom power cables, knowing the materials is key. These parts decide how well cables work and last. Let's look at the main parts: conductors, insulation, and jackets.

Conductors

Conductors are the heart of a power cable. They move electricity from one spot to another. Picking the right conductor type affects how good your cables are.

Types of Conductors

You have choices for conductors in custom power cables. Common ones are copper and aluminum. Copper is liked for its great conductivity and bendability. Aluminum is lighter and cheaper but conducts less well. Each has pros, so think about what you need when choosing.

Conductivity and Performance

Conductivity shows how well electricity flows through a conductor. Copper gives top conductivity, perfect for high-performance needs. Aluminum conducts less but works fine in many cases. When designing cables, balance conductivity with cost and weight for best results.

Insulation and Jackets

Insulation and jackets keep conductors safe from harm. They protect against weather and physical damage.

Insulation Materials

Insulation wraps around conductors to stop leaks or shorts. Common types are PVC, rubber, and Teflon. PVC is cheap and useful; rubber bends easily; Teflon handles heat well, good for hot places. Pick based on where your cables will be used.

Jacket Properties and Durability

The outer jacket guards against outside dangers like water or wear. Jackets come in materials like PVC, polyurethane, or polyethylene. PVC lasts long against chemicals; polyurethane resists wear; polyethylene stops moisture well. Choose a jacket that fits what your cables face outside.

By thinking about materials carefully, you make strong custom power cables that fit your needs perfectly.

Overcoming Common Challenges

Making custom power cables can be tricky. Knowing these problems helps you find fixes so your cables work well.

Avoiding Mixing Modular PSU Cables

Risks of Mixing Cables

Mixing PSU cables from different sources is risky. Each PSU has its own pin setup and voltage. If you mix them up, it might damage parts or break the system. This happens often in custom cable projects where specific setups are needed.

Best Practices to Prevent Issues

To stop these problems, label your cables clearly. Use colors or tags to show which cable goes with which PSU. Also, keep notes on how your cables are set up. This prevents mistakes and makes sure you connect them right. Check your cables often for damage because broken ones can cause trouble too.

Considering Environmental Factors

Temperature and Humidity Considerations

Things like heat and wetness affect cable performance. High heat can overheat them, while too much wetness causes rusting. To avoid this, pick materials that handle tough conditions well. Teflon works great in hot places; polyethylene keeps out moisture.

Protection Against Physical Damage

Physical harm is another problem for custom cables. They can get cut or crushed in rough spots. Choose strong jackets like polyurethane for protection against scratches. Use conduits or trays to guard them from getting hurt.

Case Study: Custom Cable Prototyping for Efficiency

Engineers faced issues making car electronics cables but solved them by testing early designs first. This made their solutions better, cheaper, and more reliable.

By tackling these common challenges, you make custom power cables that fit your needs and work well everywhere. Careful planning is key to solving these problems.

Easy Tips and Tools for Custom Power Cables

Making custom power cables might seem hard, but the right tools help a lot. Here are some simple tips to guide you.

Using Online Helpers

Online helpers make designing custom power cables easy. They offer many benefits:

Simple to Use: You can quickly enter what you need, like length and type. The helper then makes a design just for you.

Saves Time: It speeds up the process compared to doing it by hand.

Saves Money: Helpers stop costly mistakes by checking all details before making them.

To use helpers well, follow these steps:

Know What You Need: Understand your cable's job and where it will be used. This helps pick the right materials.

Enter Correct Info: Put in exact measurements and details into the helper. Being accurate means the final product will be right.

Check and Change: After getting a design, look at it closely. Change things if needed to make it better.

Design Expert: "Before setting up, always ask professionals for advice."

Try Custom Solutions

Custom power cables let you make solutions that fit your needs perfectly. Here’s how to use them best:

Make Cables Fit Your Needs

Find Special Needs: Think about what makes your project special. Whether it's space or power needs, knowing these helps design the best cable.

Test Prototypes: Trying out prototypes lets you improve your design. An Industry Expert says, "Testing is key for making better and cheaper cable solutions."

Encourage Readers to Try

Start using custom power cables in your projects now! Doing this boosts how well systems work. Begin with online helpers and talk with experts for success. Take this chance to make cables that fit perfectly and improve your electronics!

Custom power cables have many benefits. They make electronics work better and last longer. Use simple tips and tools to design cables that fit your needs. Online tools make it easy, saving time and money. Now is a great time to try custom solutions. Make cables perfect for your projects. Start now and see how they can change your electronics!

See Also

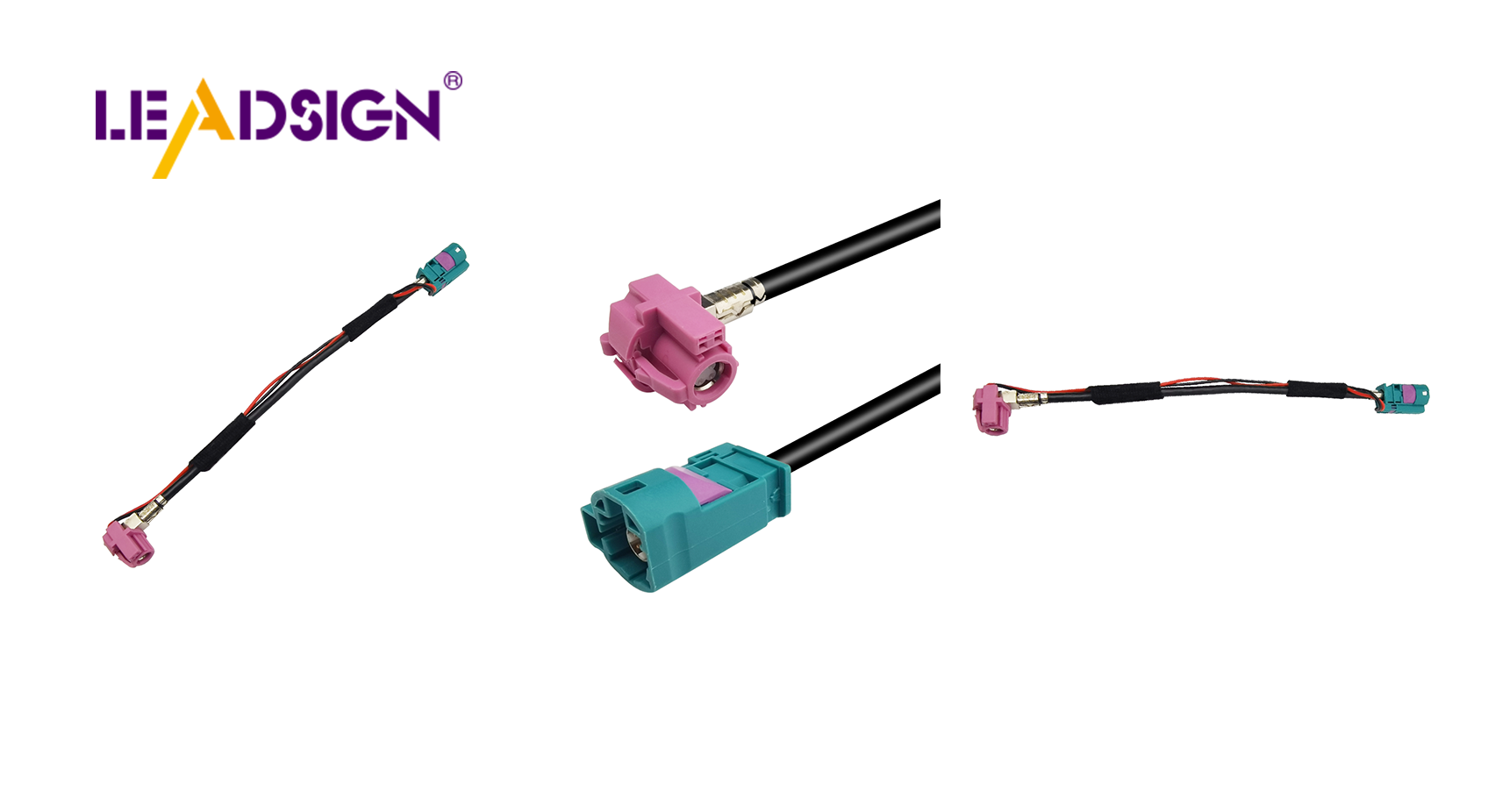

Unlocking the Potential of FAKRA Coaxial Technology

Enhancing Infotainment: Unleashing the Power of HSD to USB

The Significance of HSD Cable Integration in Contemporary Tech

The Flexibility and Advantages of FAKRA Connector Cables

Enhancing Automotive Data Transfer: Cutting-Edge Connectors and Cables