Custom Power Cables Made Easy for Beginners

Custom power cables are very important in life. They give you flexibility and efficiency. You can make them fit your needs. If you're working on car electronics or audio systems, these cables help a lot. You can improve performance by making cables that match exactly what you need. This saves time and makes your projects work better overall.

Understanding Custom Power Cables

What Are Custom Power Cables?

Definition and Overview

Custom power cables are special wires you can change to fit your needs. Unlike regular cables, you pick the length, connectors, and color. This makes sure your cables fit perfectly in projects. It works for small DIY tasks or big setups. Making custom cables gives you control over quality and how well they work.

Benefits of Customization

Customizing power cables has many perks. First, you get the right length, which keeps things tidy. No more messy wires or extra lengths in the way. Second, choose good materials for better performance and strength. Your custom cables last longer and work better than store-bought ones. Lastly, customization lets you match colors with your setup. Pick designs that make your space look neat and cool.

Common Applications

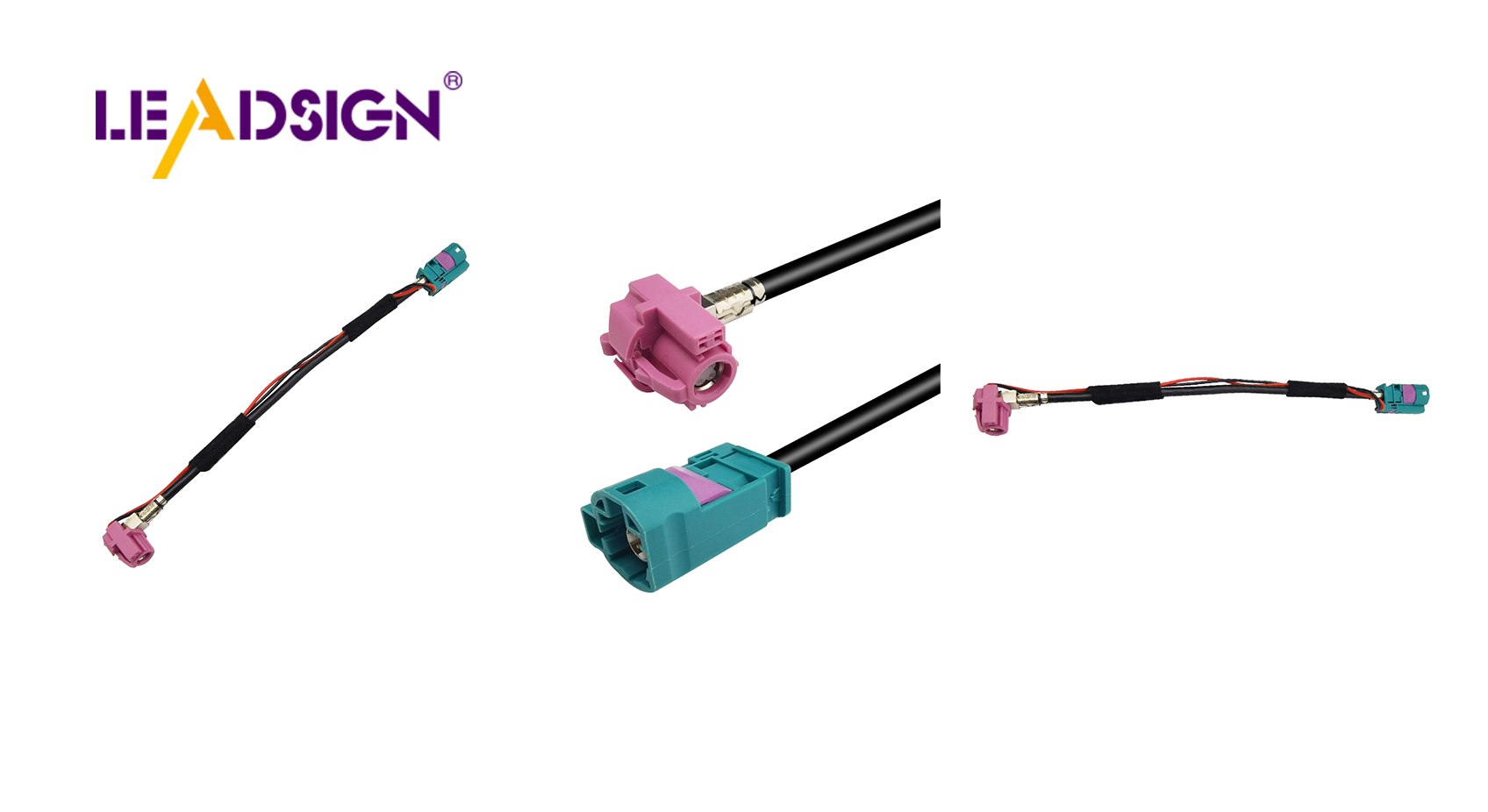

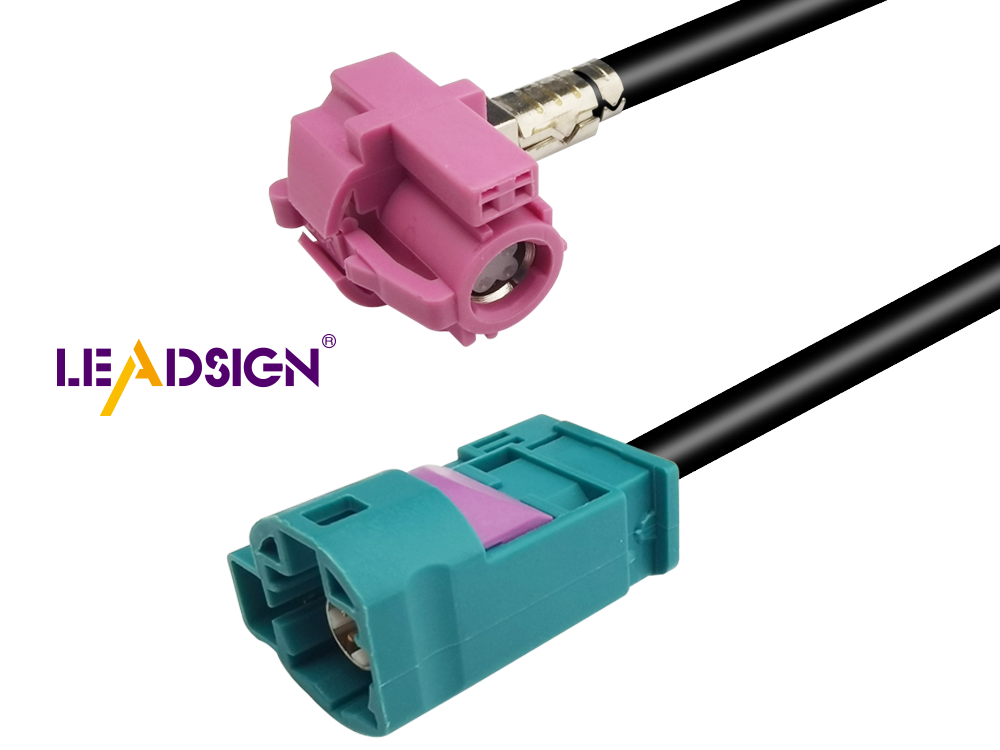

Automotive Electronics

In car electronics, custom power cables are key. They make sure all parts get the right power amount. Whether adding a new sound system or lights, these cables give flexibility and trustworthiness needed. Design them to fit tight spaces in cars for clean installs.

High-Quality Audio Setups

For music lovers, custom power cables are amazing. Good audio setups need clear sound; right cables help a lot. By customizing them, reduce noise and signal loss for great sound quality. Whether at home theaters or studios, custom power helps achieve top audio experiences.

Tools and Materials Needed

Important Tools

Wire Cutters and Strippers

To make custom cables, you need wire cutters. They cut wires to the right size. Wire strippers take off the plastic cover. This makes sure wires fit well in your project. Pick tools that are comfy to hold. This makes work easy and fun.

Soldering Gear

Soldering gear is needed for joining wires safely. A soldering iron and solder stick wires together. This makes strong links that last long. Practice on extra wires first to get better at it. This helps you feel ready for your real project.

Needed Materials

Kinds of Wires

Picking the right wire type matters a lot. There are different thicknesses and materials. Thick wires carry more power; thin ones are for small jobs. Copper wires are good because they carry electricity well. Choose what fits your project best for great results.

Connectors and covers keep cables safe and working well. Connectors join wires to gadgets, making sure they stay linked. Covers protect from harm and stop short circuits. Find connectors that match your gadgets and use good covers for long-lasting cables.

Connectors and covers keep cables safe and working well. Connectors join wires to gadgets, making sure they stay linked. Covers protect from harm and stop short circuits. Find connectors that match your gadgets and use good covers for long-lasting cables.

Step-by-Step Guide to Making Custom Power Cables

Getting the Wires Ready

Measuring and Cutting

First, measure how long the wire should be. Use a ruler or tape for this. Cut the wire with cutters after measuring. Make sure all wires are the same length if making more than one. This keeps things tidy.

Removing the Covering

Next, take off the plastic from wire ends. Use a stripper tool for this job. Strip about half an inch of cover from each end. This shows the metal inside for later connection. Be careful not to hurt the wire.

Putting Together the Cables

Joining the Wires

Now, attach wires to connectors. Put bare wire into connector slots snugly. Check they fit well for strong links. Make sure wires match your device's needs.

Soldering Steps

Time to solder! Heat up your iron and add some solder to join parts. This sticks wire to connector firmly. Practice on extra wires if new at this skill.

Checking Safety and Workability

Testing Connections

Before using cables, test them first. Use a multimeter to see if electricity flows right. If it beeps, it's good; if not, fix it.

Staying Safe

Safety is key! Work in airy places and wear goggles for eye safety. Keep your area clean and unplug gadgets before connecting cables.

Customization Tips and Applications

Personalizing Your Cables

Color Coding

Using colors helps organize cables easily. Different colors mean different things. Red might show power, blue for data. This helps you find cables fast in tricky setups. Buy colored wires or use tape to mark them. It saves time and stops mix-ups.

Labeling Techniques

Labels make cables even more organized. Write the cable’s job or where it goes. Use a marker or sticky labels. Some like using label makers for neatness. Clear labels stop mistakes and help fix problems quickly. Knowing each cable's role makes managing easy.

Exploring Advanced Applications

Home Audio Systems

Custom cables improve home audio systems a lot. Make cables fit your space just right. Shorter ones cut clutter and signal loss. Choose materials that boost sound quality too. Many pick copper or silver wires for clear sound. Customizing gives you the best listening experience.

DIY Electronics Projects

DIY projects need custom cables too. Design them for your project needs, like robots or smart homes. Pick the right length and connectors so everything fits well. Customizing ensures things work as planned, adding a personal touch to your work.

Now you know how to make custom power cables. It's your chance to try it yourself. It might seem hard at first, but practice helps a lot. Here are some last tips:

Begin Easy: Start with small projects to gain confidence.

Be Careful: Always follow safety rules.

Keep Exploring: Look at online guides and groups for more ideas.

Each project helps you get better at this skill. Enjoy creating!

See Also

Exploring the Flexibility and Advantages of FAKRA Cable Connectors

The Significance of HSD Cable Assembly in Today's Technology

Boosting Vehicle Performance with HSD to USB 2.0 Cables

Unlocking the Potential of FAKRA Coaxial Cable

Maximizing the Flexibility and Advantages of FAKRA Coaxial Connectors