Custom Power Cables: Easy Design Tips

Custom power cables are very important today. They are needed in many fields, like car electronics. These cables help devices get the right power. This makes them work better and more reliably. In cars, custom cables link parts like cameras and music systems. They also help other fields by offering special solutions. Using these cables can make things work more efficiently and meet special project needs.

Important Things to Think About in Custom Power Cables Design

When making custom power cables, think about key things. This helps them work for what you need. This part will show you important steps to design these cables well.

Picking Connectors

Choosing the right connectors is very important. Connectors link the cable and device, so picking the right one makes sure they work together well.

Types of connectors

There are many connector types for different uses. For example, CableMod Custom Cables have many connectors for different PSU models. Knowing what your devices need helps pick the right connector type.

Matching with devices

Make sure connectors fit your devices. Check pinouts to match device details. Good matches stop connection problems and make cables work better.

Figuring Out Cable Length and Thickness

The length and thickness of cables affect how they work. Finding the right length and thickness is important when designing.

Measuring needed length

To find the needed length, measure from power source to device. Think about bends or obstacles too. Right measurements help cables fit without being too loose or tight.

Picking the correct thickness

Thickness means how thick a cable is. Thicker ones carry more current, good for high-power needs. When picking thickness, think about your device's power needs to make sure cables give enough power well.

Knowing End Use

Knowing how you'll use custom power cables helps design them right for needs. This means thinking about where they'll be used and special needs of your project.

Conditions around them

Think about where custom power cables will be used. Things like temperature or chemicals can change how they work. Pick materials that handle these conditions for strong and reliable cables.

Special project needs

Every project has special needs. Like, Custom PC Cables need exact pinouts for wiring right. Knowing these needs helps design custom power cables that fit your project perfectly, making them last longer and work better.

Technical Parts of Custom Power Cables

When making custom power cables, knowing the technical parts is key. This helps your cables work well and fit your needs.

Types of Conductors

Picking the right conductor material is important for cable efficiency.

Material Choices

You have a few choices for conductors. Copper and aluminum are common. Copper is great because it conducts well and bends easily. Aluminum is lighter and cheaper but doesn’t conduct as well. Choose based on what you need and your budget.

Conductivity Thoughts

Conductivity affects how cables work. Copper’s high conductivity makes it good for strong power transfer. Aluminum works for less demanding tasks. Think about your device’s power needs to pick the best material.

Flexibility and Flex Life

Flexibility and flex life matter for cable strength and use.

Why Flexibility Matters

Flexible cables are easy to set up. They bend without breaking, which helps in tight spots. CableMod Custom Cables are more flexible than regular ones, helping with setup and looks.

Checking Flex Life

Flex life means how often a cable can bend before breaking. For lots of movement, pick cables with long flex life. This makes them last longer, so you replace them less often.

Not Mixing Cables

Mixing different brands or models can cause problems.

Dangers of Mixing

Different brands might wire differently even with the same connectors. This can lead to mismatches or damage to devices. Knowing compatibility stops these issues.

Good Practices

To avoid problems, use cables made for your power supply or device. Stick to one brand or check guides for fit. This keeps custom power cables safe and working well.

Tools for Making Custom Power Cables

Having the right tools helps make custom power cables easily. Use software and physical tools to create cables that fit your needs.

Design Software

Design software lets you plan your custom cables before building them. It gives a digital space to try different setups.

What to Look For

When picking software, look for features like:

Changing cable length and thickness.

Choosing connector types.

Seeing color designs and covers.

Testing how cables work in different situations.

These help ensure your design works well and meets your needs.

Popular Software Choices

Many designers use popular software options like:

AutoCAD Electrical: Known for great electrical design tools.

SolidWorks Electrical: Offers strong tools for making electrical systems.

CableMod Configurator: Lets you design cable sets, pick covers, set lengths, and choose colors.

These tools help make efficient and nice-looking custom power cables.

Physical Tools

Software helps plan, but physical tools are needed to build cables. They ensure accurate and safe assembly.

Important Assembly Tools

To build custom power cables, you'll need:

Wire cutters and strippers to prepare wires.

Crimping tools to attach connectors tightly.

Heat shrink tubes and a heat gun for safety covering.

These tools help make strong and useful cables.

Safety Gear

Safety is key when working with electricity. Make sure you have:

Insulated gloves to avoid shocks.

Safety goggles to protect eyes from bits flying around.

A multimeter to check if cables work right with voltage.

Using the right safety gear reduces risks. By mixing design software with proper physical tools, you can make custom power cables that suit your needs perfectly.

Why Custom Power Cables Are Great

Custom power cables have many good things. They make projects look nice and work better. You can make them fit just right for what you need.

Look Better

Choose How They Look

With custom power cables, pick colors, lengths, and connectors. This helps match your device or style. Bright colors can make it pop, or soft ones for a neat look. Picking how they look makes sure they work well and look great too.

Neat and Tidy

Custom cables do more than just add color. They fit well in your setup, making it tidy. A neat setup looks good and is easy to fix if needed. Custom cables turn messy wires into a clean space that looks cool.

Work Better

Fit Just Right

Custom power cables are made to fit your devices perfectly. This helps them work their best. In car factories, special cables help make more cars with fewer problems. Like one cable helped a factory save time and money by working better.

Last Longer

Custom power cables are strong and last long. They handle the places you use them without breaking easily. This means you don't have to change them often, saving money over time. One cable saved a company lots of money by lasting longer and working more hours.

Designing custom power cables needs a few important steps. Think about connector types, cable length, and materials. This helps make cables that work well and look nice. Custom cables are flexible and efficient. They are a smart choice for many uses.

Customer Testimonial: "I love my custom CableMod cables for my Corsair SF600. They bend better and look nicer than the original ones." - Happy Customer

Use custom power cables to make projects better. They not only look good but also work well, giving long-lasting value and happiness.

See Also

Enhancing Automotive Data Transfer: Cutting-Edge Connectors and Cables

Optimizing Entertainment: Harnessing the Power of HSD to USB Cables

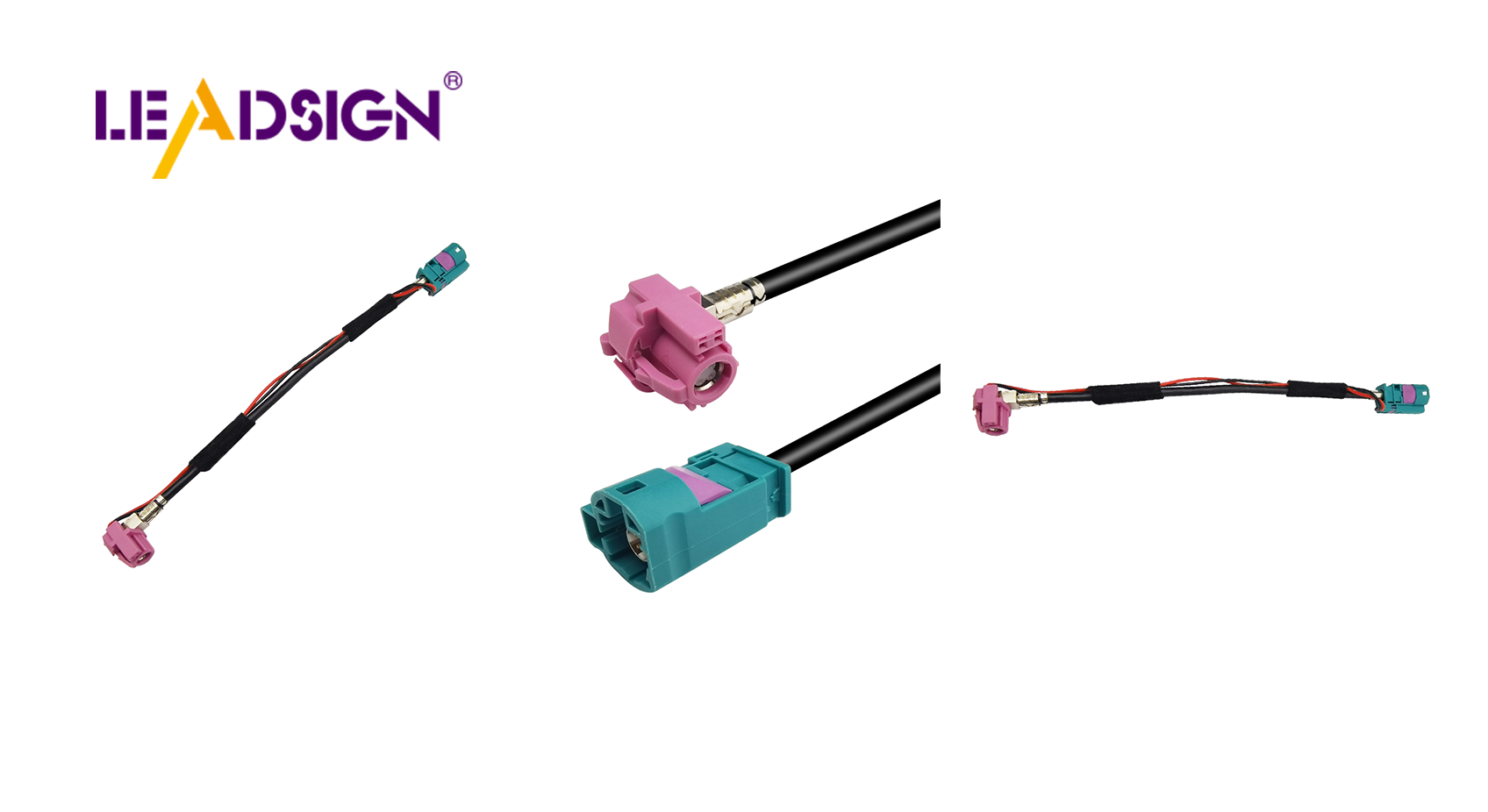

Exploring the Flexibility and Advantages of FAKRA Cable Connectors