Custom Automotive Connectors and Cables for US Manufacturers

Custom RF cables and wire connectors play a crucial role in automotive applications, ensuring optimal performance. American manufacturers utilize specialized custom RF cables and wire connectors to meet their specific requirements. Coax connectors provide robust connections for a variety of uses, enhancing the reliability of automotive systems. Cable connectors contribute to the safety and efficiency of car systems. Customizing these connections solutions allows manufacturers to address unique needs, resulting in superior and more competitive products.

Uses of Custom Connectors and Cables

High-Frequency Car Uses

Car Radios

Car radios need special connectors to work well. These connectors help send clear signals. They make radio sound better in cars. Makers get better communication systems.

GPS Devices

GPS devices need strong connections. Special cables help with accurate directions. Good connectors ensure correct tracking. Makers get improved results with custom solutions.

Bluetooth Systems

Bluetooth needs good connectors to work right. Custom ones help move data between gadgets. Special cables make using them easier. Makers add cool features with custom designs.

Other Car Uses

Mobile Phone Systems

Mobile phone systems need strong links. Custom wire connectors keep them steady. Tailored cables help smooth talking. Makers create better products with these ideas.

Keyless Entry Systems

Keyless entry needs safe connections. Custom connectors make systems reliable. Special cables stop unwanted access. Makers offer safer cars with these changes.

Important Companies in the Field

Custom Connector Corporation

Unique Roles

Custom Connector Corporation is a top company in cars. They make smart connection solutions. Their skill with relay sockets makes them special. With 40 years of work, they make great products. They use parts made in America. Custom Connector Corporation gives strong and lasting connectors.

Special Skills

Custom Connector Corporation makes special connectors for clients. They design items to fit what customers want. New ways of making things improve their products. They solve problems for tricky car systems. Quality checks are very important to them. They aim to keep customers happy with custom fixes.

AVX and Other Firms

Unique Roles

AVX is great at making car connectors. They create items for specific needs. New tech helps AVX do well. They offer special connections for many uses. AVX helps build fast cars. The company stays big in the car world.

Special Skills

AVX is good at tough connector designs. They focus on new ideas and accuracy. AVX helps with high-frequency needs. Their products keep signals clear and strong. AVX makes sure things last even when it's rough outside. They help makers with flexible design choices.

Technical Parts of Connectors and Cables

Kinds of Connectors and Cables

Custom RF Cables

Custom RF cables are key for car systems. They send signals well. These cables fit different uses. Makers use them to boost car performance. Custom RF cables are flexible and dependable.

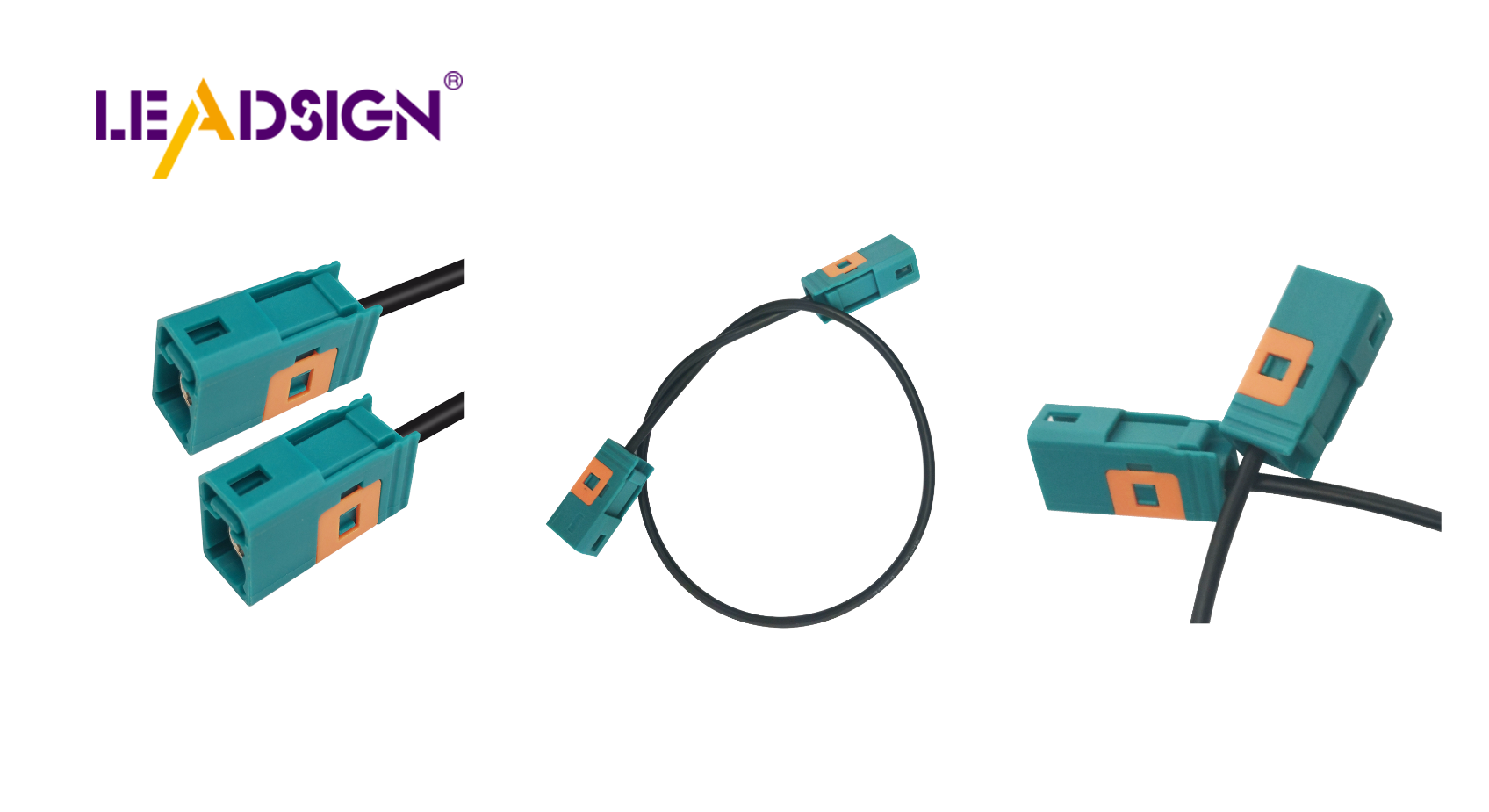

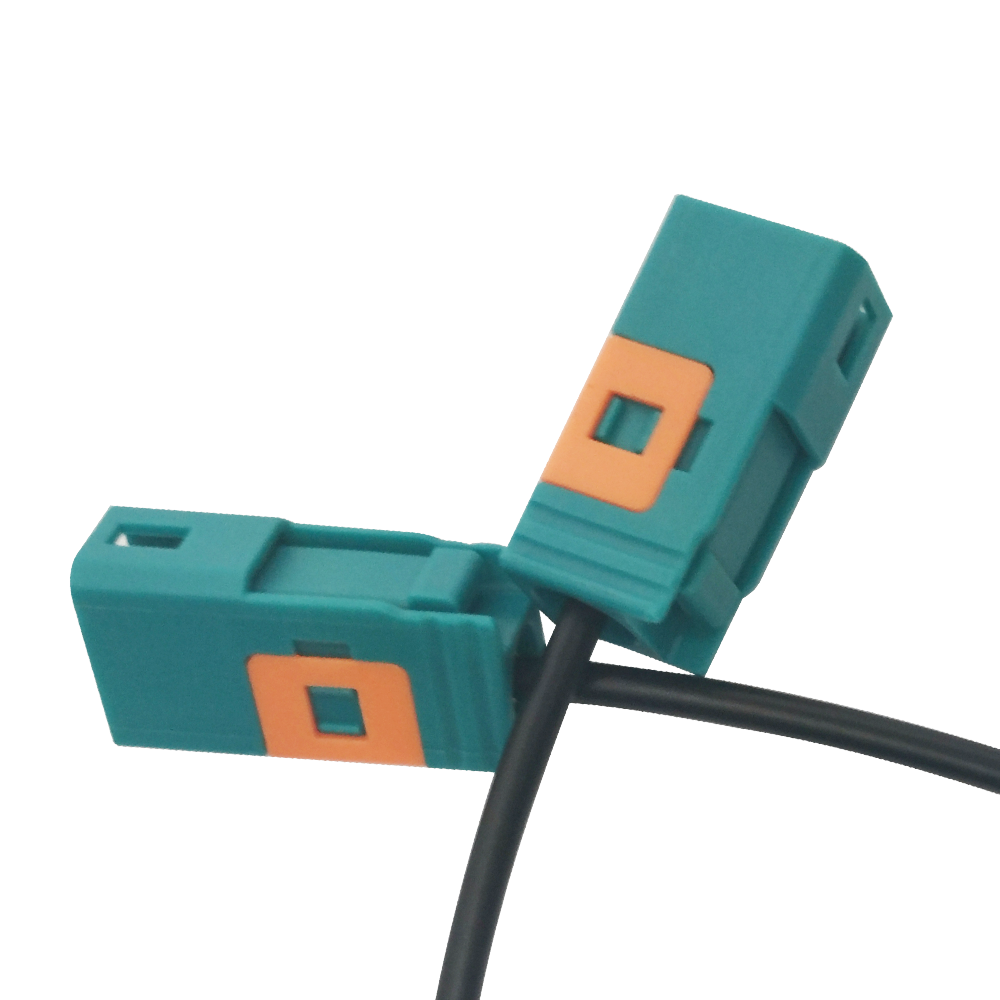

Coax Connectors

Coax connectors are important in cars. They give strong, steady links. Coax connectors work with high-frequency tasks. Makers trust them for good performance. Coax connectors keep signals clear in tough spots.

Design Thoughts

Picking Materials

Choosing materials is big in making connectors. Engineers pick based on strength and flow of electricity. Right materials make them last long. Makers choose ones that handle rough conditions well. Material choice affects connector quality.

Environmental Things

Environment affects connector design too. Engineers think about heat, wetness, and shaking. Connectors must survive harsh places in cars. Makers build them to fight environmental stress. This makes sure they work well everywhere.

Making Them Special

Checking What Clients Want

Understanding client needs helps make custom parts. Engineers look at what clients need closely. This helps make perfect solutions for each use case. Makers aim to give exact, useful products based on client ideas.

Trying Out Designs

Making samples checks if designs work right. Engineers test these samples for how they perform. Tests check if they meet rules set by the industry standards . Makers change designs from test feedback . Samples and tests ensure top-notch custom parts.

Benefits of Custom Solutions

Better Performance

Stronger Signal Quality

Custom solutions make signals better in cars. Engineers design connectors to keep signals strong. Good materials help clear communication. Makers get great performance with these solutions.

Less Interference

Custom cables stop interference in car electronics. Engineers use special shields to block noise. This keeps systems working well without problems.

More Reliability

Tough in Hard Conditions

Custom connectors last in tough spots. Engineers pick strong materials for hard places. These parts handle heat and shaking well. Cars work reliably with tough connectors.

Steady Quality Checks

Custom solutions ensure steady quality checks. Makers test parts carefully. Each piece meets industry rules. Reliable performance comes from steady quality checks.

Fitting Client Needs

Special Design Plans

Custom solutions fit what clients need exactly. Engineers work closely with clients. Special designs meet unique needs. Makers give products that match client wants.

Changeable Making Steps

Custom solutions use changeable making steps. Makers change how they make things for clients' needs. This helps different project sizes fit well. Clients get quick and good solutions with flexible steps.

Custom connectors and cables are very important for car makers. They make car systems work better and last longer. Custom designs fit exact needs of each maker. These special parts help companies stay ahead in the market. Think about using custom connectors and cables for better products. Use these chances to improve car tech with well-made solutions.

See Also

Enhancing Auto Data Transfer: Cutting-Edge Connectors and Cables

Discovering Opportunities: Rapid FAKRA-Mini Connectors in Auto Sector

The Significance of Fakra Connectors in Auto Sector