The Critical Role of OEM Connectors in Automotive Wiring Connector Types

Good wiring is crucial in cars, especially when it comes to automotive electrical connectors types. It plays a vital role in ensuring that various parts function effectively by facilitating the flow of electricity. These wires must possess durability to withstand vibrations and harsh weather conditions. OEM connectors, known for their high quality, significantly enhance the performance and reliability of vehicles. Among the various automotive electrical connectors types are blade and pin connectors, which are essential for maintaining the safe and efficient operation of critical components such as airbags and engines.

Understanding OEM Connectors

Definition and Characteristics

What are OEM Connectors?

OEM connectors are special parts made by the original maker for a specific car. These parts help the car work well with its systems. They are made to be very good quality, fitting perfectly and keeping the car's electric systems safe. Using OEM connectors, makers make sure the car’s wires work safely and well.

Key Features of OEM Connectors

OEM connectors have important features that make them vital in cars:

Durability: They can handle heat, shaking, and weather, lasting long.

Compatibility: Made to fit a certain car, they work smoothly with its systems.

Quality Assurance: They come with promises of quality and protection, saving on repairs.

Advanced Design: New ideas like better seals and shake resistance, as seen in Triton Series by ITT Inc., suit tough car conditions.

Importance in Automotive Industry

Ensuring Safety and Reliability

In cars, safety is key. OEM connectors help keep cars safe. They give strong connections to stop electric problems that might make driving unsafe. Their strong build keeps electric parts working even when it's hard, making cars safer.

Enhancing Performance and Efficiency

OEM connectors help cars perform better. As more people want electric cars, smart wire systems are needed more. OEM connectors make sure these systems run well, helping new tech like power steering and driver aids. By moving electricity smoothly, they make cars run better and use less energy efficiently.

Looking at Car Electrical Connector Types

Car electrical connectors are very important. They help car parts work by sending electricity and signals. Car electrical connectors are very important. They help car parts work by sending electricity and signals.

Common Car Electrical Connectors

Blade Connectors

Blade connectors are often used in cars. They connect wires with a flat piece that fits into a slot. This makes them easy to use and take out. They are good for places like fuse boxes because they are simple and reliable.

Pin Connectors

Pin connectors have a pin-and-hole design. The pin goes into the hole, making it stay connected well. These are used in car wiring for things like engines and lights. Their design helps stop them from coming loose, keeping the car’s electric system working well.

Special Car Electrical Connectors

Waterproof Connectors

Waterproof connectors keep water out, which stops rust and short circuits. They have seals to protect connections in wet places like headlights or sensors.

High-Temperature Connectors

High-temperature connectors can handle heat near engines or exhausts. They use strong materials that don’t break down in high heat, helping parts like turbochargers work safely.

Research Findings:

New studies show better materials make connectors handle more data and tough conditions.

New high-voltage connectors help electric cars work better.

Car connector types keep getting better to make cars safer and run smoothly. Makers use new designs so these parts meet tough needs today.

Challenges and Solutions in Car Wiring

Common Wiring Problems

Rust and Tear

Rust and tear are big problems in car wiring. These happen because of water, salt, and weather. Over time, rust can damage metal parts of connectors. This makes electricity flow poorly and systems might fail. Tear happens from the car moving a lot. It can make connectors loose or wires break. This weakens the electric system, hurting how the car works and its safety.

Electric breakdowns in cars come from bad connectors, broken wires, or poor insulation. These issues cause power to cut off sometimes or parts to stop working. In new cars, electronics are very important. Failures here can mess up engines, safety tools, and entertainment systems. Fixing these problems is key for keeping cars safe and working well.

Electric breakdowns in cars come from bad connectors, broken wires, or poor insulation. These issues cause power to cut off sometimes or parts to stop working. In new cars, electronics are very important. Failures here can mess up engines, safety tools, and entertainment systems. Fixing these problems is key for keeping cars safe and working well.

Fixes and Good Habits

Regular Check-Ups

Regular check-ups help stop wiring troubles. By checking connectors often, mechanics find rust or tear early on. Cleaning them and adding protective layers stops rusting. Making sure connectors are tight prevents wear problems too. Doing regular checks keeps the car’s electric system lasting longer.

Using top-quality connectors is vital for good electric links. OEM connectors are strong and well-made, better than normal ones. They handle tough car conditions well against rust and tear. By choosing top-quality parts, makers lower electric breakdowns a lot which boosts car performance and safety.

Using top-quality connectors is vital for good electric links. OEM connectors are strong and well-made, better than normal ones. They handle tough car conditions well against rust and tear. By choosing top-quality parts, makers lower electric breakdowns a lot which boosts car performance and safety.

Case Study: Trustworthy Car Wiring Connectors

Ensures steady electric links in cars.

Shows why strong materials matter.

Proves how quality parts keep cars safe.

In short, fixing common wiring issues with regular care and using great connectors is key for good car electric systems. Following these tips helps keep cars safe, reliable, and efficient.

OEM connectors are very important in car wiring. They keep cars safe and working well. These connectors fit perfectly with certain car models. Picking the right connector is key. It stops damage and keeps the car's warranty safe. Car experts should focus on using good, reliable connectors. This helps cars work better and prevents problems. Stressing how important OEM connectors are can make cars safer and run smoother on the road.

See Also

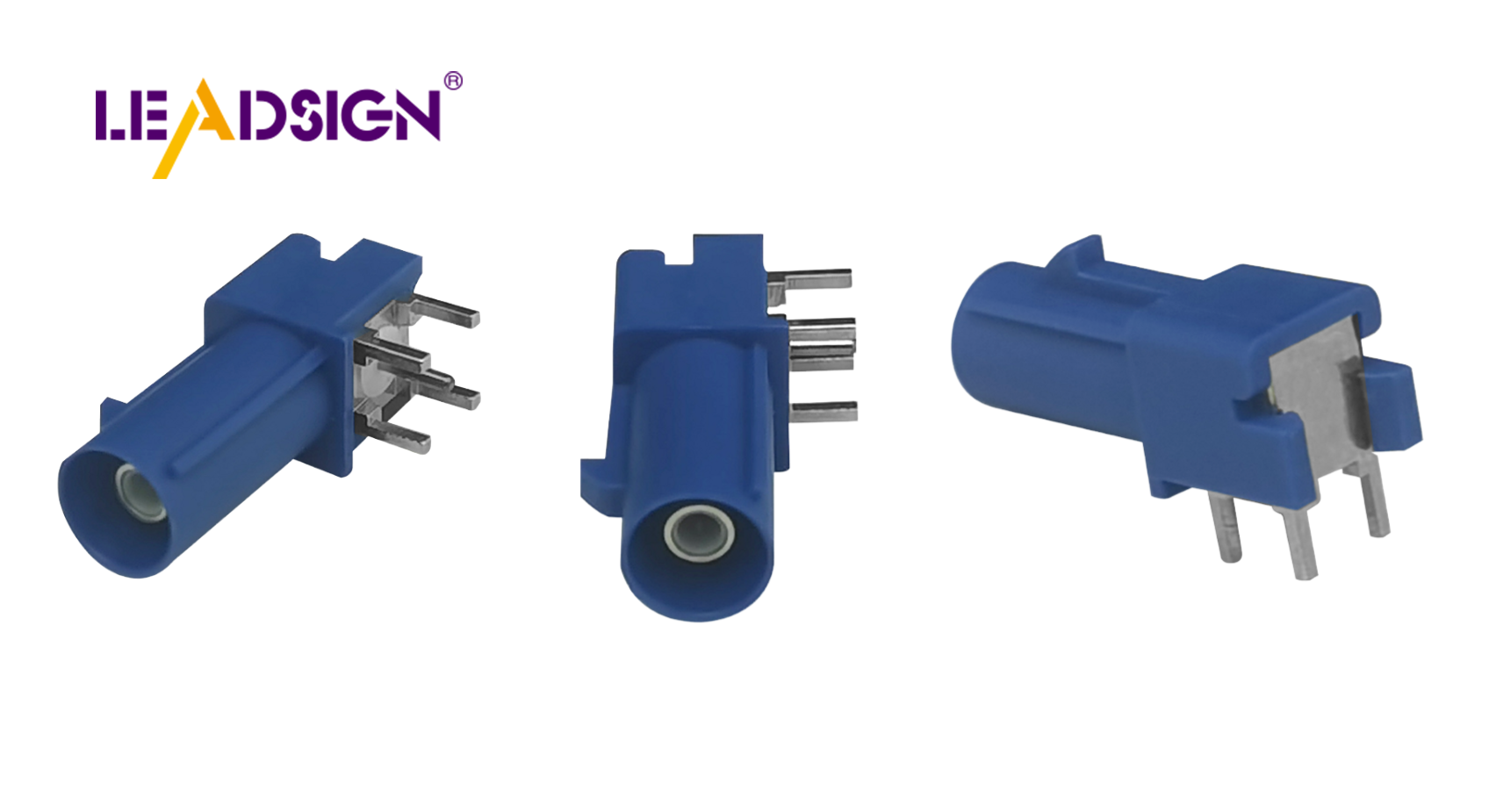

Significance of Fakra Connectors in Automotive Sector

Essential Role of Fakra Connectors in Contemporary Cars

Fundamentals of HSD Connectors in Auto Sector