Comprehensive Look at Wire Connectors Automotive Type

Automotive wiring connector types are crucial components in cars. They play a vital role in ensuring that electrical parts function harmoniously. These connectors facilitate the connection of various components such as radios and fuel injectors, contributing to the smooth operation of the vehicle. Available in a variety of shapes and sizes, automotive wiring connectors are designed to fit into tight spaces and perform specific functions. With robust contacts and waterproof features, they are safeguarded against heat and rust. Understanding the different automotive wiring connector types is essential for maintaining optimal car performance and is integral to modern automotive technology.

Understanding Wire Connectors

What are Wire Connectors?

Wire connectors are important in cars. They join wires to keep connections stable. These connectors come in many shapes and sizes for different car parts. Their main job is to help electricity move between things like the battery and engine or radio and speakers. By keeping connections strong, wire connectors help cars work well.

Why are they essential in automotive systems?

Wire connectors are key in car systems. They make sure electrical parts work smoothly together. Without them, the system would often break down, causing problems. For example, high-power connectors charge batteries well. They also protect against heat, water, and rust found in cars. This protection keeps them working long and reliably.

Basic Components

Conductors

Conductors are the heart of wire connectors. They let electricity pass from one part to another. Usually made of copper or aluminum, they conduct electricity well with little resistance for good energy flow. In cars, conductors must handle tough conditions like heat and shaking.

Insulation

Insulation covers the conductor as a shield. It stops electricity from leaking out and prevents short circuits. Made of rubber or plastic, it resists heat and moisture for durability. In cars, insulation is crucial for safety and performance.

Terminals

Terminals link the wire to devices or parts. They can be crimped or soldered on for easy use or better security. Terminals hold wires tight so they don't come loose or disconnect easily. In cars, terminals need to withstand movement and shaking, making their design important for reliability.

Automotive Wiring Connector Types

Automotive wiring connector types are important for car electrical systems. They help different parts talk to each other, making the car work well and safe. Knowing about the different connectors helps pick the right one for each job.

Crimp Connectors

Crimp connectors are very common in cars. They make a strong connection by squeezing the connector onto the wire.

Features and Benefits

Durability: Crimp connectors stay strong and last long. They can handle shaking and stress, perfect for cars.

Ease of Use: You need few tools to install them. A crimping tool is enough to attach them fast.

Versatility: They come in many sizes and shapes, fitting different wires and uses.

Common Applications

Battery Connections: Crimp connectors often join battery cables because they are tough.

Lighting Systems: Used in headlights and taillights, they keep electricity flowing well.

Engine Components: Crimp connectors connect sensors and engine parts, helping them talk easily.

Solder Connectors

Solder connectors give a lasting, good connection. They use melted solder to join wires with connectors.

Features and Benefits

High Conductivity: Solder connectors let electricity flow well, cutting down energy loss.

Secure Connection: The solder makes a strong link that won’t come apart by accident.

Resistance to Corrosion: The solder stops moisture from causing rust, so they last longer.

Common Applications

Circuit Boards: Solder connectors are used on control units and circuit boards.

Audio Systems: They make sure sound moves clearly in car audio systems.

Sensitive Sensors: Solder connectors keep sensors connected for accurate data sharing.

Push-On Connectors

Push-on connectors or quick-connects let you connect wires fast without tools.

Features and Benefits

Convenience: You can quickly plug or unplug wires, making fixing things easy.

Secure Fit: Their design holds tight so connections don’t get loose.

Space Efficiency: Push-on connectors fit into small spaces inside cars.

Common Applications

Fuse Boxes: Often used in fuse boxes for fast access.

Dashboard Components: They link switches on the dashboard easily.

Accessory Installations: Great for adding extras like GPS units or dash cams.

Knowing these automotive wiring connector types helps choose the best one for each task, keeping car electrical systems working their best.

Key Makers and Brands

Main Makers

TE Connectivity

TE Connectivity is a top name in car wire connectors. They make connectors that work well even in tough places. Their products last long and work great, so many car makers like them. TE Connectivity has lots of connectors for different car uses, helping cars run safely.

Molex

Molex is big in the car connector world too. They focus on new ideas and good quality, making connectors for today's cars. Molex connectors can take high heat and shaking found in cars. Their promise to do well makes them trusted with parts for simple to advanced car systems.

Famous Brands

Delphi

Delphi is famous for its great car connectors. They have many products for things like engines, safety, and entertainment in cars. Delphi's connectors give strong links to keep cars working their best. Their focus on new ideas and quality gives them a good name.

Amphenol

Amphenol is a top brand with many car connectors. Known for being strong and reliable, Amphenol's products are used from engine systems to smart driving aids (ADAS). Their items handle tough car conditions, giving long-lasting use to both makers and owners.

In Spain, companies like SADECA also help the car connector field grow. Started in 1983, SADECA leads in making cables as good as original ones. Their push for new ideas shows the spirit of the car industry, keeping vehicles running well.

Picking the Right Wire Connector

Choosing the right wire connector is important for a car's electrical system. The correct one makes sure connections are strong and avoids problems.

Things to Think About

Matching with Car Systems

When picking a wire connector, it must fit the car's systems. Every car has special electrical needs, and the connector should match them. A good match means everything works well together. It also stops electrical issues that can mess up how the car runs.

Strength and Trustworthiness

Strength and trustworthiness matter when choosing a wire connector. Cars have bumpy rides, heat, and rust that affect connectors. A strong connector handles these things, lasting long. Trustworthy connectors work well all the time, stopping electrical problems.

Tips for Installing

Installing wire connectors right is key to their success. Doing it correctly makes sure they connect safely and work well.

Needed Tools

Putting in wire connectors needs certain tools. A crimping tool is needed for crimp connectors to fit tightly. Soldering tools are used for solder connectors to make a solid link. Push-on connectors might need pliers for tight fitting. Having these tools makes installing easier and better.

Mistakes to Avoid

Avoid common mistakes when installing to keep connectors working well. Using the wrong type of connector can cause bad performance. Bad crimping or soldering leads to loose connections too. Making sure everything fits right stops these issues and keeps connectors reliable.

In short, picking the right wire connector means thinking about matching, strength, and good installation steps. These help keep a car's electrical system running smoothly.

Choosing the right wire connectors is very important for cars. They keep connections strong and safe from heat and water. New technology has added features like self-cleaning parts and built-in seals to make them better. Companies like SADECA in Spain make these new connectors, helping the industry grow. As technology changes, knowing and picking the right connectors is key for cars to work well.

See Also

Exploring HSD Connector Advantages in Automotive Sector

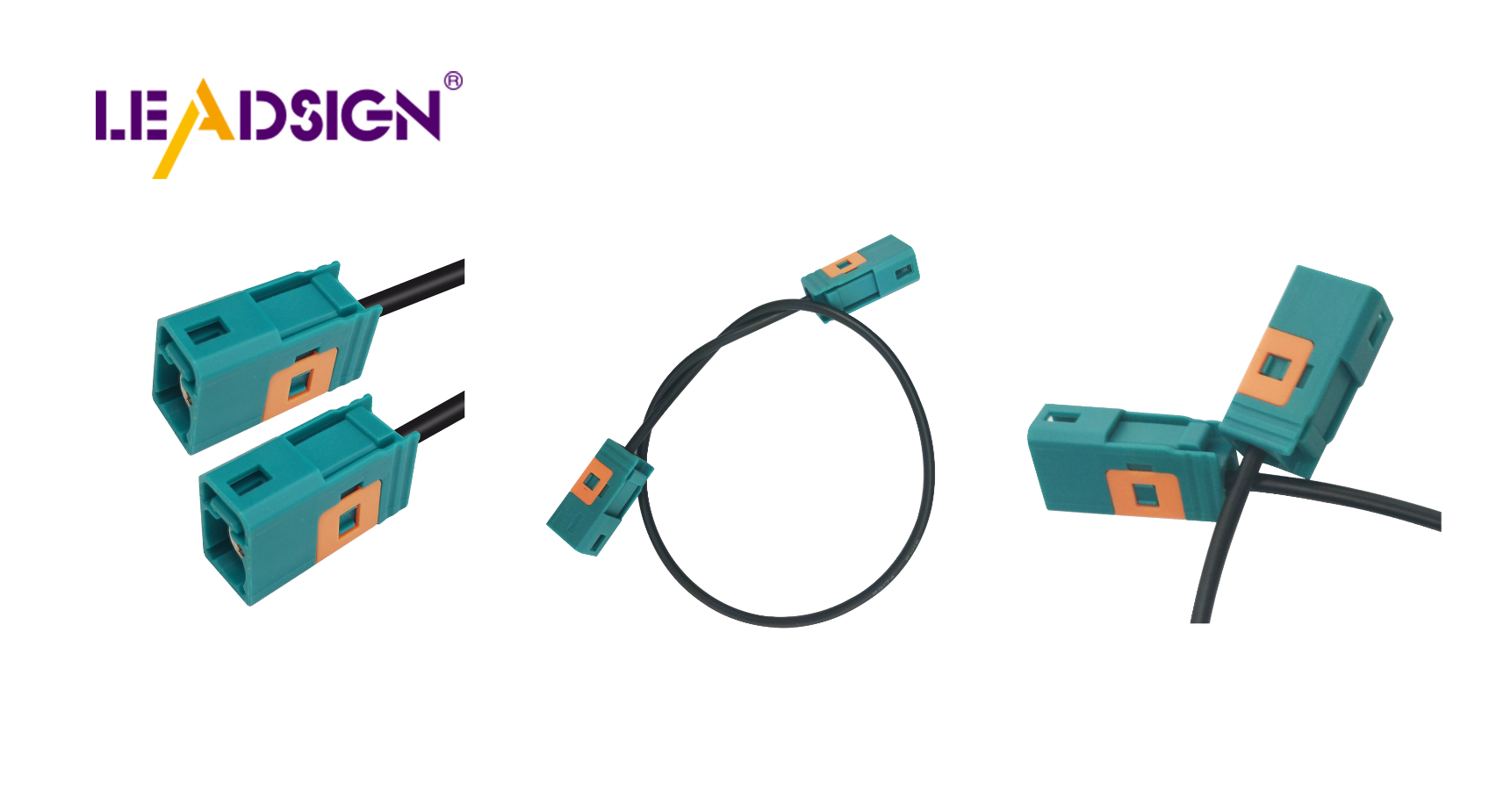

Uncovering Advantages of Fakra Connectors in Auto Industry

Significance of Fakra Connectors in Auto Sector