Comprehensive Look at Wire Connectors Automotive Type

Automotive wiring connector types are crucial in cars. They play a vital role in connecting various components to the electrical system. Understanding the different types of automotive wiring connectors is essential for effectively repairing vehicles. These connectors come in various shapes and sizes, each serving a specific purpose in maintaining the safety and functionality of the vehicle by facilitating proper electrical connections. Familiarizing oneself with these connector types enables individuals to select the most suitable ones for their automotive tasks.

Basics of Wire Connectors

What are Wire Connectors?

Wire connectors are key parts in car systems. They link wires to make sure connections are safe and strong. These connectors can be plugs, sockets, or terminals. Each type is made for different wiring jobs. Using wire connectors helps mechanics handle the many wires in cars.

How do they work in car systems?

In cars, wire connectors help electricity flow between parts. They make sure power gets to lights, sensors, and controls. Connectors keep the electrical system safe by stopping short circuits and loose links. By giving a steady connection, wire connectors boost how well and safely a car works.

Importance in Car Industry

Role in car safety and performance

Wire connectors are very important for car safety and performance. They make sure all electric parts work right, which keeps the car safe to drive. For example, brake system connectors must work well to stop crashes. Engine system connectors help the engine run better by spreading power well.

Impact on electrical system efficiency

A car's electrical system works best with good wire connectors. Good ones cut down resistance and save energy, making fuel use better and cutting pollution. They also stop electric problems that cost money to fix. Using good wire connectors makes cars last longer and work better.

Historical Evolution of Wire Connectors

Early Developments

Initial designs and materials

Wire connectors have changed a lot over time. At first, engineers used simple stuff like copper and brass. These metals helped conduct electricity but didn't last long. The first designs were basic, using clamps or screws to join wires. They worked but needed fixing often because they wore out.

Evolution in automotive applications

When cars became popular, better wire connectors were needed. Engineers made new ones just for cars. They used plastics and alloys that insulated well and resisted weather changes. This made them strong against heat and shaking in cars. Over time, these changes improved car electrical systems.

Modern Innovations

Advances in materials and technology

Recently, wire connectors got a tech boost. Makers use silicone and thermoplastics now for better insulation and flexibility. These materials handle high heat and don't rust easily. Modern connectors also lock well to prevent loose connections.

Today, car makers keep improving wire connector tech. A big trend is smart connectors that check their own health with sensors. They warn if they get too hot or loose before issues grow big. Another trend is making them smaller for electric cars where space matters a lot. As tech grows, current trends in automotive connectors will keep being key in car systems.

Today, car makers keep improving wire connector tech. A big trend is smart connectors that check their own health with sensors. They warn if they get too hot or loose before issues grow big. Another trend is making them smaller for electric cars where space matters a lot. As tech grows, wire connectors will keep being key in car systems.

Types of Automotive Wire Connectors

Pig Tail Connectors

Features and Applications

Pig tail connectors join wires to car parts. They have a short wire with a connector at one end. This makes it easy to connect to other wires. Mechanics use them when direct links are hard. They help fix or change broken wires without redoing the whole system.

Advantages and Disadvantages

Pig tail connectors have good points. They make connecting wires easier, so less rewiring is needed. Their design helps avoid harming current wires during setup. But they also have downsides. Extra wire can clutter tight spots. Wrong setup might cause loose links, hurting the electric system's work.

Terminal Blocks

Features and Applications

Terminal blocks hold many wires together safely. They are rows of terminals in a block for neat wiring. In cars, terminal blocks manage tricky wiring systems well. They're used in fuse boxes and control panels needing many connections.

Advantages and Disadvantages

The main plus of terminal blocks is organizing multiple links securely. They stop short circuits by keeping wires apart. Also, they make fixing problems easier. But terminal blocks can be big, not fitting small spaces well. Setup needs care to keep all links secure.

Bullet Connectors

Features and Applications

Bullet connectors are round for quick wire links. They have male and female parts that snap together tightly. Bullet connectors are used in car lights where frequent changes happen.

Advantages and Disadvantages

Bullet connectors have perks too. Their shape allows fast linking, saving time on setups and fixes. They give strong connections against shaking or moving around too much but aren't great for high power jobs as repeated use wears them out.

Automotive Wiring Connector Types

Different Kinds of Connectors

Car wiring connectors come in many shapes. Each has a special job in the car's electrical system. They keep wires connected safely, helping the car work well and stay safe. Here are some common ones: HSD Cable assembly

Pig Tail Connectors: These have a short wire with a connector at one end. They're great for joining wires to parts when direct links are tough.

Terminal Blocks: These hold many wires together securely, often found in fuse boxes.

Bullet Connectors: They are round and make quick connections, used often in car lights.

Scotch Locks: These tap into existing wires without cutting them, making repairs easy.

Flat Connectors: Made for flat wires, they're used in car lights.

Round Connectors: Used where strong connections are needed, like sensors.

Square and Rectangular Connectors: Not as common but used where space is tight or many pins are needed.

Each type helps the car's electrical system work better and more reliably.

How to Pick the Right Connector

Choosing the right car wire connector depends on several things. Here's what to think about:

What You Need It For: Know what you need it for. Use bullet connectors for quick light changes; terminal blocks for complex setups.

Where It Will Be Used: Think about where it will be used. Get connectors that resist heat and rust if it's hot there.

Power Needs: Match the connector to how much power it needs to carry. High-power jobs need strong connectors that won't overheat.

Space Available: Check how much space there is for the connector. In small spaces, use smaller ones like square or flat types.

Easy to Install? Choose ones that are easy to put in and fix later. Quick-connect types like bullet connectors save time during repairs.

By knowing these points, people can pick the best connectors for their needs, keeping cars working well and safely.

Installation Techniques

Tools and Equipment Needed

Important tools for setup

To put in car wire connectors right, you need some tools. These make sure the connection is safe and works well. Here's a list of key tools:

Wire Strippers: These take off the plastic cover from wires without harm.

Crimping Tools: They press connectors onto wires to hold them tight.

Screwdrivers: Used to turn screws on terminal blocks.

Multimeter: This checks if electricity flows and measures voltage.

Heat Gun: It makes heat shrink tubing fit snugly over connections.

Safety steps

Staying safe is very important when installing. Follow these safety tips:

Wear Safety Gear: Put on gloves and goggles to keep hands and eyes safe.

Turn Off Power: Always switch off the car's power before starting work.

Work in Bright Light: Good lighting helps prevent mistakes and accidents.

Use Insulated Tools: Insulated tools stop electric shocks.

Check for Loose Wires: Make sure all wires are tight to avoid shorts.

Step-by-Step Setup Guide

Getting the wires ready

Getting wires ready right means a good setup. Do these steps:

Cut the Wire: Use cutters to trim the wire to needed length.

Strip Off Covering: Take away about half an inch of covering with strippers.

Twist Wire Ends: Twist bare wire ends together so they don't fray.

Pick Right Connector: Choose a connector that fits the wire size.

Attaching and securing connectors

After getting wires ready, attach and secure connectors:

Put Wire In Connector: Place bare wire end into connector hole.

Crimp Connector On Wire: Use crimper tool to squeeze connector onto wire tight.

Test Connection Strength: Gently pull wire to check it's attached well.

Add Heat Shrink Tubing: Slide tubing over joint, use heat gun for snug fit, adding protection.

Verify Connection Works: Use multimeter to check if connection is good.

By doing these steps with right tools, people can set up car wire connectors safely and well. This ensures strong electrical links, helping cars run better and safer.

Common Issues and Maintenance

Troubleshooting Common Problems

Finding bad connectors

Bad wire connectors cause car problems. Spotting them early stops bigger issues. Look for flickering lights or sensors not working. Power cutting out can mean a loose connector. Check connectors for rust, color change, or damage. Use a multimeter to see if they work right.

Once you find a bad connector, fixing common problems. Clean rusty ones with a brush or cleaner. This helps them work better. Tighten loose ones with the right tool for a snug fit. Replace broken connectors with new matching ones. Test fixed connections with a multimeter to make sure they work.

Once you find a bad connector, fix it. Clean rusty ones with a brush or cleaner. This helps them work better. Tighten loose ones with the right tool for a snug fit. Replace broken connectors with new matching ones. Test fixed connections with a multimeter to make sure they work.

Maintenance Tips

Regular care keeps connectors good. Regular checks and cleaning. Check them often for wear or damage signs. Clean with a soft brush or air to remove dirt. Use grease on moist-exposed connectors to stop rusting and keep them reliable.

Regular care keeps connectors good. Check them often for wear or damage signs. Clean with a soft brush or air to remove dirt. Use grease on moist-exposed connectors to stop rusting and keep them reliable.

Keeping them working long-term

For long-lasting use, follow some rules: Use top-quality connectors that meet standards for better performance and durability; don't overload them as too much power causes overheating; secure tightly to avoid shaking issues. By doing this, cars stay safe and efficient.

Q&A Section

Frequently Asked Questions

How to pick the right connector?

Choosing the best wire connector for cars needs some thought:

Know What It’s For: Figure out what job the connector will do. Bullet connectors are great for quick light changes. Terminal blocks are better for tricky wiring.

Think About Where It Is: Look at where it will be used. In hot places, use connectors that can handle heat and won’t rust.

Check Power Needs: Match the connector to how much power it carries. Strong connectors stop overheating in high-power jobs.

Look at Space Available: See how much room there is for the connector. Small spaces might need flat or square ones.

Easy to Put In? Pick connectors that are easy to install and fix later. Quick-connect types like bullet connectors save time during repairs.

By thinking about these things, people can choose connectors that help cars work well and stay safe.

What shows a bad connector?

Spotting a bad wire connector stops more car problems:

Lights Flicker: Flickering lights mean a loose or rusty connector.

Power Cuts Out: Sudden power loss means a bad connection needing fast fixing.

See Damage: Check for rust, color change, or breaks on connectors. These show a weak spot.

Feels Hot: Too much heat near a connector means poor connection or too much power going through it.

Use Multimeter: Test with a multimeter. Odd readings show hidden problems.

Fixing these signs quickly keeps electrical links strong and cars safe and working well.

Wire connectors are very important in cars. They help the car's electrical system work well, keeping it safe and running smoothly. Picking the right connectors means thinking about what they do, where they go, and how much power they need. Taking care of them regularly makes them last longer and work better. Knowing about new connector technology helps people choose wisely, making cars more efficient and safe. By learning these things, you can make sure car systems work their best for a long time.

See Also

Exploring the Advantages of HSD Automotive Connectors

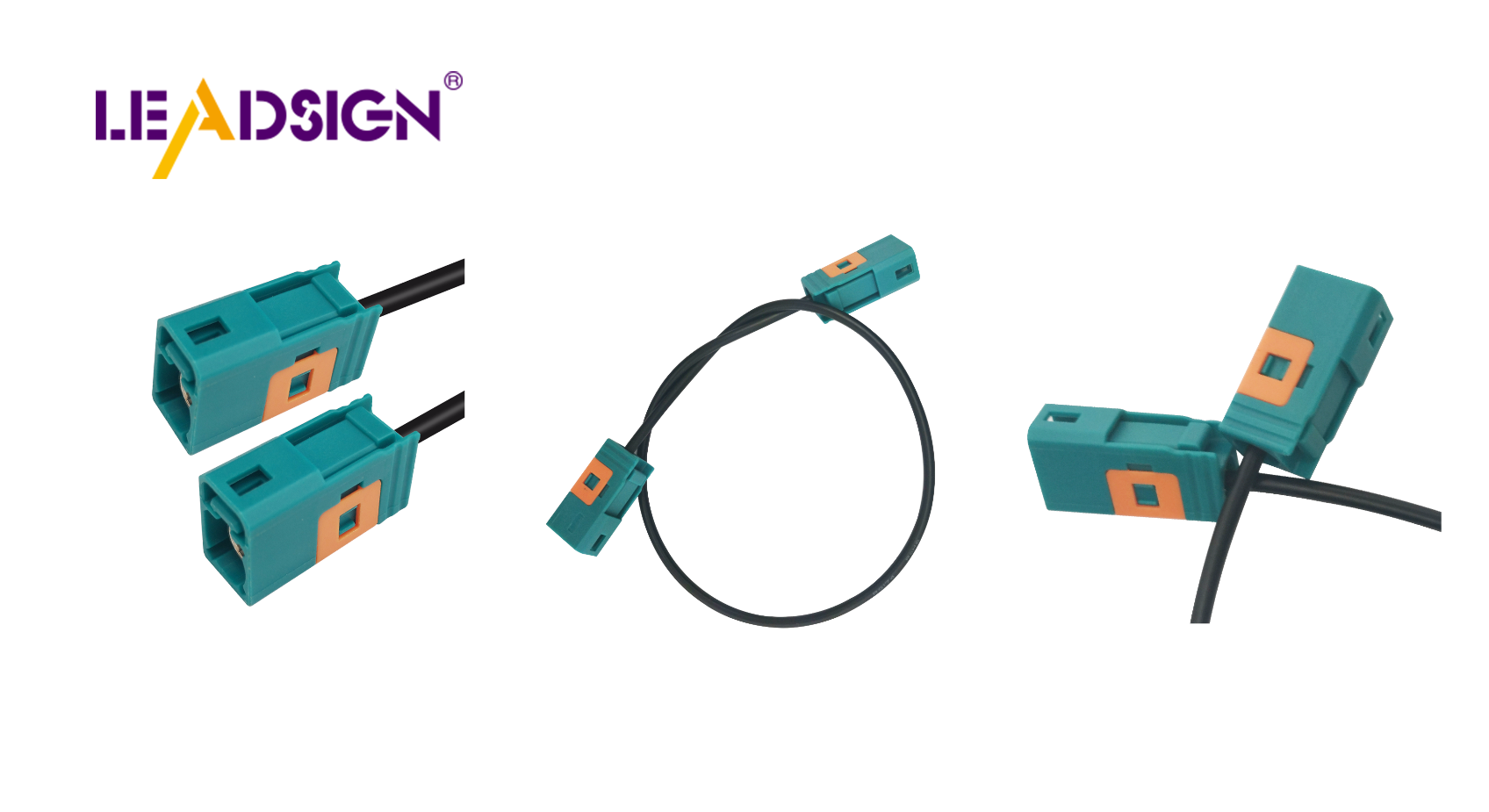

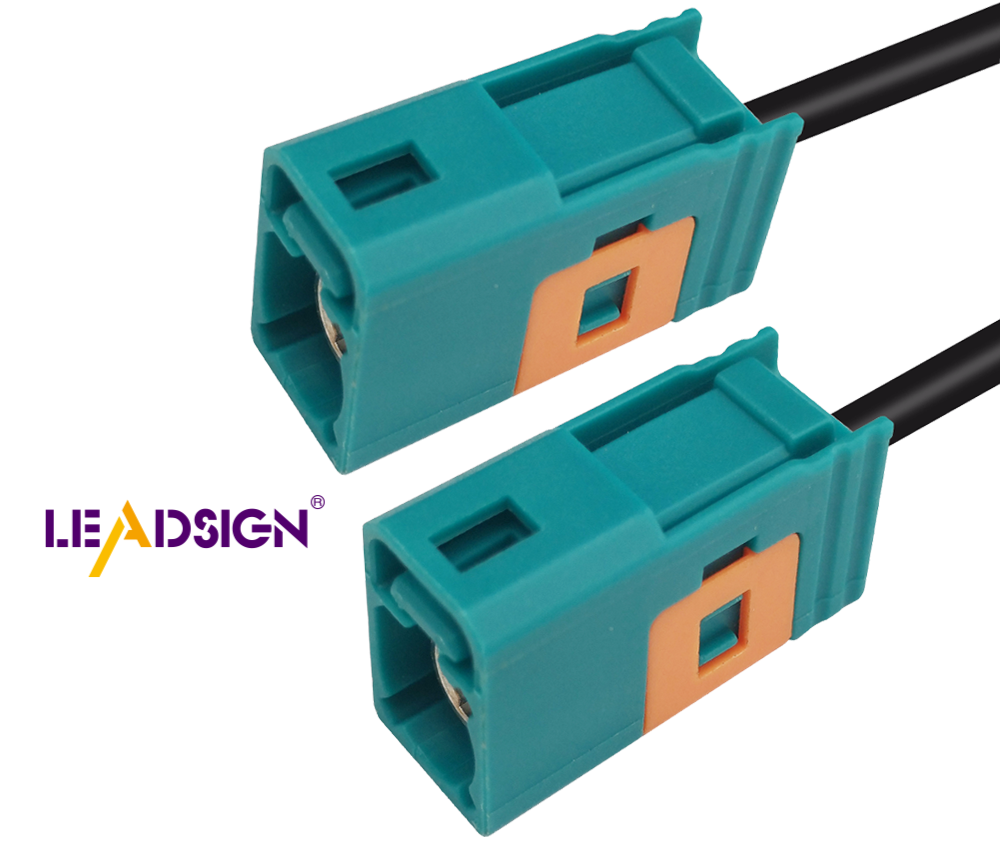

Discovering the Advantages of Fakra Auto Connectors

Significance of Fakra Connectors in Auto Sector