The Complete Guide to Automotive Wiring Connector Types

Understanding automotive wiring connectors is crucial for anyone involved in vehicle maintenance or repair. These connectors play a vital role in ensuring the smooth operation of your vehicle's electrical systems. They connect various components, allowing electricity to flow seamlessly. The market for these connectors is growing rapidly, with a 5.8% annual growth rate projected through 2026. This growth highlights their importance in the evolving automotive industry. You will encounter a wide variety of automotive electrical connectors types, each designed to meet specific needs and challenges. Grasping their complexity can enhance your ability to maintain and troubleshoot vehicle systems effectively.

Overview of Automotive Wiring Connectors

Definition and Purpose

What are wiring connectors?

Wiring connectors, often referred to as auto connectors or automotive electrical connectors, serve as the vital links in your vehicle's electrical system. They join wires and components, ensuring the seamless transmission of power and data throughout the vehicle. As vehicles become more advanced, these connectors have evolved to enhance their performance and durability. You will find them in various shapes and sizes, each designed to fit specific applications within the vehicle.

Why are they essential in automotive systems?

Automotive wiring connectors play a crucial role in maintaining the integrity and functionality of your vehicle's electrical systems. Without them, connecting different parts of the car's wire harness would be nearly impossible. They allow for quick and secure installation, ensuring that power and signals are efficiently transmitted. This efficiency is vital for the smooth operation of everything from the engine bay to the vehicle's interior electronics. By using high-quality connectors, you can prevent electrical failures and ensure reliable performance.

Basic Components of Connectors

Pins and Sockets

At the core of every connector are the pins and sockets. These components form the bridge between different circuits, allowing electrical signals to pass through seamlessly. Typically, connectors include male (plug) and female (socket) components. The design and size of these pins vary depending on their application. For high-current applications, larger pin sizes provide maximum contact area, ensuring a stable connection. Materials like copper, brass, or bronze are commonly used due to their high conductivity and resistance to corrosion.

Housing and Insulation

The housing and insulation of a connector protect the pins and sockets from environmental factors. The housing encases the internal components, providing structural support and protection against physical damage. Insulation materials prevent electrical shorts and ensure that the connector operates safely under various conditions. These features are especially important in automotive environments, where connectors may be exposed to moisture, heat, and vibration. By choosing connectors with robust housing and effective insulation, you can enhance the durability and reliability of your vehicle's electrical system.

Types of Automotive Wiring Connectors

Understanding the different automotive electrical connectors types is essential for anyone working with vehicle wiring systems. Each type serves a unique purpose and offers specific benefits and drawbacks. Let's explore some common connector types you might encounter.

Blade Connectors

Applications and Characteristics

Blade connectors, often referred to as spade connectors, are among the most common automotive electrical connectors types. You will find them in applications where quick and easy connections are necessary. These connectors consist of a flat, blade-like metal piece that fits into a corresponding slot. They are typically used in low-voltage applications, such as connecting wires to switches or relays.

Advantages and Disadvantages

Blade connectors offer several advantages. They provide a secure connection that can be easily disconnected when needed. This feature makes them ideal for situations where frequent disconnection is required. However, they may not be suitable for high-vibration environments, as the connection can become loose over time. Additionally, they are not always the best choice for high-current applications due to their limited contact area.

Ring and Spade Connectors

Applications and Characteristics

Ring and spade connectors are versatile automotive electrical connectors types used in various applications. Ring connectors have a circular end that fits over a bolt or stud, while spade connectors have a forked end that slides under a screw. These connectors are commonly used in grounding applications and battery connections.

Advantages and Disadvantages

The primary advantage of ring and spade connectors is their secure attachment. Once fastened, they provide a reliable connection that resists loosening. This makes them ideal for high-vibration environments. However, they require tools for installation and removal, which can be a disadvantage in situations where quick disconnection is necessary. Additionally, improper installation can lead to poor connections and potential electrical failures.

Butt Connectors

Applications and Characteristics

Butt connectors are another popular type of automotive electrical connectors types. They are used to join two wires end-to-end, creating a continuous electrical path. These connectors are often used in repair and maintenance tasks, where wires need to be extended or repaired.

Advantages and Disadvantages

Butt connectors offer a simple and effective way to join wires. They provide a strong, permanent connection that resists pulling apart. This makes them ideal for applications where a secure connection is crucial. However, they require crimping tools for installation, which can be a disadvantage if you do not have the necessary equipment. Additionally, they are not easily disconnected, making them less suitable for applications where frequent disconnection is required.

Understanding these automotive electrical connectors types will help you choose the right connector for your specific needs. Consider factors such as application, environment, and ease of use when selecting connectors for your vehicle's electrical system.

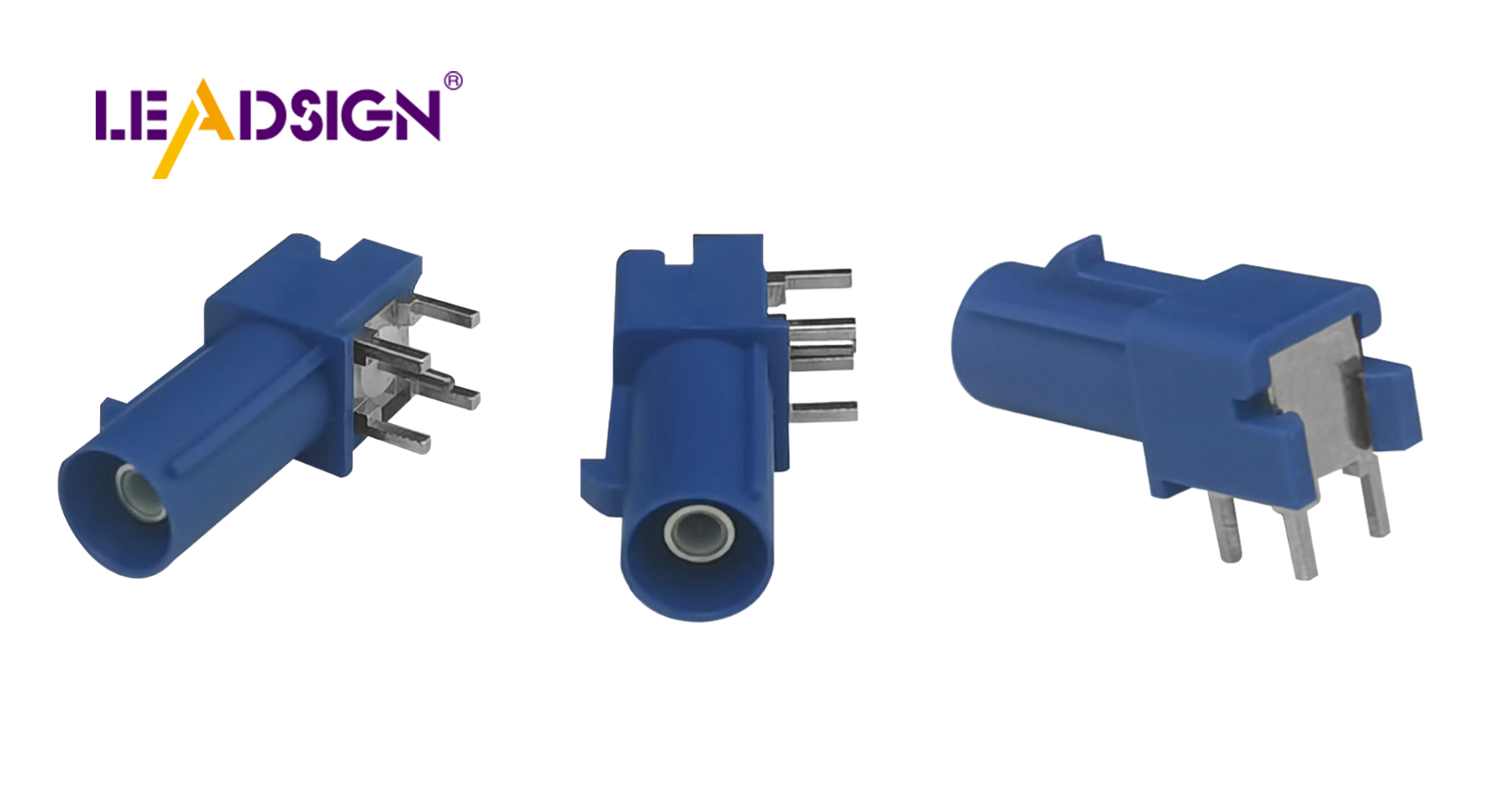

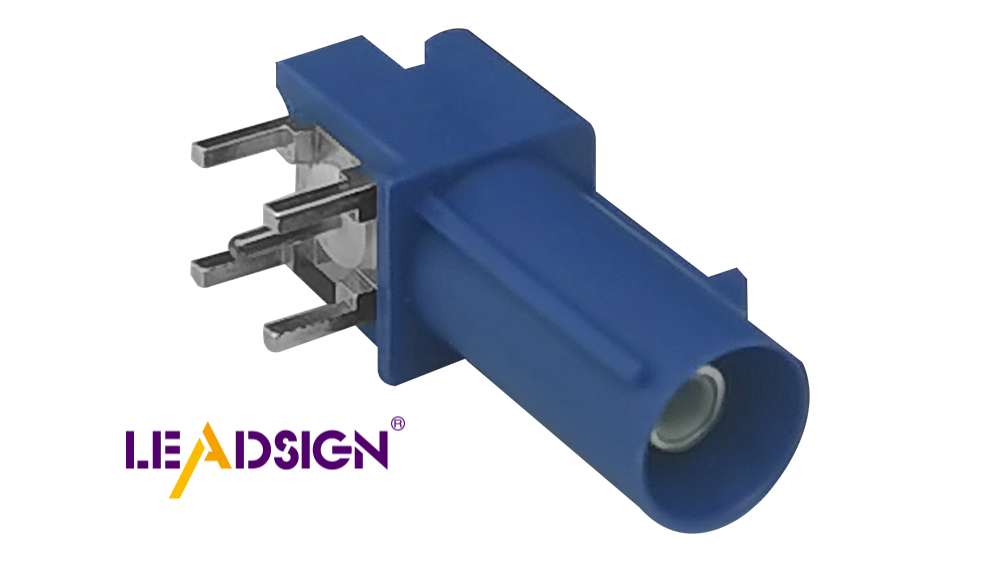

FAKRA Connectors

Applications and Characteristics

FAKRA connectors stand out among automotive electrical connectors types due to their specialized design for high-frequency applications. You will find these connectors in systems that require reliable radio frequency (RF) connections, such as GPS antennas, radio antennas, and infotainment systems. Their unique coding system prevents misuse, ensuring that each connection is secure and precise. This feature makes FAKRA connectors ideal for complex automotive environments where multiple RF connections are necessary.

These connectors come in various configurations, including straight and right-angle cable connectors, PCB connectors, and panel connectors. They support high data rates up to 8 Gbps, making them suitable for modern vehicles equipped with advanced communication systems. The robust design of FAKRA connectors includes primary and secondary locking systems, which enhance assembly security and prevent accidental disconnections.

Advantages and Disadvantages

FAKRA connectors offer several advantages that make them a preferred choice among automotive electrical connectors types. Their secure coding system ensures that connections are made correctly, reducing the risk of errors. The connectors' durable construction withstands harsh automotive environments, including extreme temperatures ranging from -40 °C to +105 °C. This resilience ensures long-lasting performance, even in challenging conditions.

Moreover, FAKRA connectors provide excellent signal integrity, which is crucial for maintaining the quality of RF transmissions. Their high-density design allows for the combination of power, signal, and other connections, offering flexibility and future-proofing for evolving automotive technologies.

However, FAKRA connectors also have some disadvantages. Their specialized design can make them more expensive compared to other automotive electrical connectors types. Additionally, the installation process may require specific tools and expertise, which could pose a challenge for those unfamiliar with these connectors. Despite these drawbacks, the benefits of FAKRA connectors often outweigh the costs, especially in applications where reliability and performance are paramount.

Factors to Consider When Choosing Connectors

When selecting automotive electrical connectors types, you must consider several factors to ensure optimal performance and reliability. These factors include electrical requirements, mechanical requirements, and safety and compliance standards.

Electrical Requirements

Current and Voltage Ratings

You need to match the connector's current and voltage ratings with your vehicle's electrical system. This ensures that the connector can handle the electrical load without overheating or failing. For example, if your application involves high-current circuits, choose connectors with larger pin sizes and higher current ratings. This will prevent potential damage and ensure a stable connection.

Environmental Conditions

Consider the environment where the connector will be used. If it will face moisture, dust, or extreme temperatures, opt for weatherproof connectors. These connectors have robust housing and insulation to protect against environmental factors. FAKRA connectors, for instance, are designed to withstand harsh conditions, making them suitable for automotive applications.

Mechanical Requirements

Durability and Material

The durability of automotive electrical connectors types depends on the materials used in their construction. Choose connectors made from high-quality materials like copper or brass, which offer excellent conductivity and resistance to corrosion. Durable connectors ensure long-lasting performance, even in demanding automotive environments.

Ease of Installation

Ease of installation is crucial when selecting connectors. Look for connectors that offer straightforward installation processes. TE Connectivity connectors, for example, are known for their ease of installation and maintenance. This feature saves time and reduces the risk of errors during assembly.

Safety and Compliance

Industry Standards

Ensure that the connectors you choose comply with industry standards. Compliance guarantees that the connectors meet specific safety and performance criteria. FAKRA connectors meet USCAR and FAKRA 2 standards, ensuring compatibility and reliability in automotive applications.

Quality Assurance

Quality assurance is vital when selecting automotive electrical connectors types. Choose connectors from reputable manufacturers that provide quality assurance measures. This ensures that the connectors have undergone rigorous testing and meet high-quality standards, reducing the risk of failures.

By considering these factors, you can select the right automotive electrical connectors types for your vehicle's needs. This will enhance the performance and reliability of your vehicle's electrical system, ensuring safe and efficient operation.

Common Issues and Troubleshooting

Connector Failures

Causes of Failures

Automotive wiring connectors can fail for several reasons. You might encounter failures due to corrosion, which occurs when moisture seeps into the connector. This can lead to poor electrical conductivity. Vibration from the vehicle's movement can also loosen connections over time. Additionally, using connectors that do not match the wire gauge or electrical load can cause overheating and eventual failure.

Scientific Research Findings:

Investing in high-quality connectors is crucial for vehicle performance. High-quality connectors resist corrosion and withstand vibrations better than low-quality ones. They ensure robust connections in automobile systems, as highlighted by Eigen Engineering.

Prevention and Maintenance

To prevent connector failures, you should regularly inspect and maintain your vehicle's connectors. Ensure that all connections are tight and secure. Use dielectric grease to protect connectors from moisture and corrosion. Choose connectors that match the wire gauge and electrical load to avoid overheating. Regular maintenance helps in identifying potential issues before they lead to failures.

Troubleshooting Techniques

Identifying Faulty Connectors

Identifying faulty connectors involves a systematic approach. Start by visually inspecting the connectors for signs of corrosion, damage, or loose connections. Use a multimeter to check for continuity and ensure that the connectors are transmitting electricity properly. If you notice any irregularities, the connector might be faulty.

Scientific Research Findings:

Automotive electrical connectors provide reliable connections between electrical circuits, inhibiting interference and ensuring optimal car performance. Ensuring that connectors are in good condition is vital for maintaining vehicle performance, as noted by Spain Auto Parts.

Repair and Replacement Tips

When you identify a faulty connector, you should repair or replace it promptly. For minor issues like loose connections, tightening the connector might suffice. However, if the connector is corroded or damaged, replacement is necessary. Use connectors that meet industry standards and match your vehicle's specifications. This ensures compatibility and reliability.

Scientific Research Findings:

Key Factors for Choosing Automotive Connectors include ensuring the electrical system works correctly and connecting different electronic devices. Selecting the right connectors for replacement is crucial, as emphasized by Suqin SZ Connectors.

By understanding common issues and employing effective troubleshooting techniques, you can maintain the integrity of your vehicle's electrical system. Regular maintenance and timely repairs will enhance the performance and reliability of your automotive wiring connectors.

Choosing the right automotive connectors is crucial for maintaining your vehicle's electrical system. The correct connectors ensure safety and efficiency, preventing potential failures. You must consider factors like electrical requirements and environmental conditions when selecting connectors. Staying informed about new developments in connector technology can enhance your understanding and ability to make informed choices. As vehicle technologies improve, connectors face new challenges, making it essential to keep up with advancements. By doing so, you ensure that your vehicle remains reliable and performs optimally.

See Also

Navigating Ford Fakra Connectors: A Complete Overview

In-Depth Analysis of HSD Connectors in Various Industries

Essential Knowledge on HSD Connectors for Automotive Sector