The Complete Guide to Automotive Electrical Connectors Types

Automotive electrical connectors types are crucial components in modern vehicles. They play a vital role in transmitting power and data efficiently, which is essential for the proper functioning of cars. With the increasing shift towards electric vehicles, the demand for these connectors is on the rise. This trend is driven by the desire for enhanced safety features and the growing popularity of electric cars. The global market for automotive electrical connectors is projected to grow by 5.8% annually until 2026, underscoring their significance in the evolving automotive industry. Understanding the various types of automotive electrical connectors is essential for both vehicle maintenance and design.

Learning About Automotive Electrical Connectors

Main Parts and Jobs

Automotive electrical connectors have important parts. Each part has a job to help electronic parts in cars talk to each other well.

Connectors

In cars, connectors can be wire-to-wire, board-to-wire, or device links. These types of connectors fit different electric needs, making sure parts talk smoothly.

Terminals

Terminal connectors are vital in car wiring systems. They make it easy to join wires or terminals to circuits and systems. This stops shortages and avoids splicing, saving space on panels. Types of wire terminals include ring terminals, spade terminals, and butt connectors for specific uses.

Housings

Housings protect connectors and terminals by covering them. They keep out things like water, dust, and heat changes. This keeps the connections inside the car safe and working well for a long time.

Usual Uses in Cars

Car electrical connectors are used in many car systems, each needing special kinds of connectors to work best.

Engine Systems

In engine systems, connectors send signals and power between the engine control unit and sensors or actuators. These links help the engine work well and respond right when driving.

Lighting Systems

Lighting systems need connectors to connect power to lights. These must handle tough conditions so lights work right, keeping cars safe.

Infotainment Systems

Infotainment systems need connectors that can move data for sound, video, and maps. These ensure smooth talking between infotainment units and other electronics for a better experience for drivers and riders.

Knowing these main parts helps pick the right connectors for car systems so they work best.

Types of Automotive Electrical Connectors

Knowing different car connector types helps cars work well. They are grouped by design, job, and use, each doing special tasks in car electronics.

By Design

Connectors have different looks for various car needs. Here are some common ones:

Blade Connectors

Blade connectors have flat metal parts. They fit into slots for a strong hold. These are used where you need to unplug quickly, like fuse boxes.

Pin Connectors

Pin connectors have round pins that fit into holes. They're popular because they're easy and reliable. They keep important systems like engines working well.

Butt Connectors

Butt connectors join two wire ends together. They're used to connect wires in cars safely, stopping shorts and keeping power flowing.

By Function

Connectors also differ by what they do in the car's system:

Power Connectors

Power connectors handle lots of electricity. They're for things needing much power, like starters. They must resist heat and shaking.

Signal Connectors

Signal connectors send small signals between parts. They're key for sensors where signal quality matters most.

Data Connectors

Data connectors move digital info fast. They're vital for radios and maps, needing good shielding from noise.

By Application

Where you use them affects which connector to pick:

Waterproof Connectors

Waterproof connectors block water and dirt. Used where it's wet or dirty, they keep working even when wet.

High-Temperature Connectors

High-temperature connectors stand up to heat well. Used near engines, they stay strong under hot conditions.

Quick Disconnect Connectors

Quick disconnects let you separate parts fast. Used where frequent unplugging is needed, making fixes easier.

By knowing these groups, you can choose the right car connector type for any job.

Picking the Right Connectors

Choosing car connectors needs knowing key things. These help connectors work well in cars.

Power Needs

Voltage Level

Voltage level is important for picking connectors. It shows the highest voltage a connector can take safely. Picking the right voltage stops electric problems and keeps it safe. For example, high-voltage cars need higher voltage connectors than regular ones.

Current Level

Current level shows how much power a connector can handle. Choosing the right current level stops overheating and damage. Systems needing lots of power, like starters, need high current connectors to work well.

Weather Factors

Heat Handling

Heat handling is needed for hot places. High-heat connectors are used near engines where it's very hot. These stay strong even when it's super hot.

Water Protection

Water protection keeps water out of connectors. Waterproof ones are good for wet spots like under cars or outside parts. They stop rust and keep connections working long.

Strong Build

Toughness

Toughness matters for picking connectors. Strong ones handle bumps and shakes in cars well. This keeps them connected over time, lowering failure chances.

Easy Setup

Easy setup makes connecting parts simple. Easy-to-use connectors save time and lower mistakes during fixes or checks. Quick disconnects let you fix things fast.

As per Wiring Harness News, weather and signal strength matter when picking car connectors. These ensure chosen ones fit their jobs, working well in different conditions.

By knowing these points, people pick the best car connector types easily. This helps make sure they meet power, weather, and build needs for their uses.

Tips for Installing and Taking Care of Connectors

Installing and taking care of car connectors is important. It helps cars work well. This part gives tips on tools, how to install, and care.

How to Install Right

Putting in connectors right keeps the car's electric system strong. Here are tools and steps you need:

Tools You Need

To put in car connectors, you need these tools:

Wire Strippers: Take off wire covers.

Crimping Tools: Attach ends to wires.

Screwdrivers: Fix connectors in place.

Multimeter: Check if connections work.

Steps to Follow

Do these steps to install well:

Get Wires Ready: Use strippers to take off half an inch of cover.

Pick the Right End: Choose an end that fits the wire size.

Attach the End: Put it on the wire and crimp tight.

Put into Connector Case: Push until it clicks in place.

Check Connection: Use a multimeter to see if it's good.

Best Ways to Care

Taking care of connectors stops problems and makes them last longer: Taking care of connectors

Look Often

Check often for early signs of trouble:

Look Closely: See if there’s wear or damage on parts.

Test Tightness: Make sure all parts stay tight.

Clean Well

Cleaning keeps connectors working well:

Use Cleaners: Clean dirt from parts with contact cleaners.

Avoid Strong Chemicals: Don’t use things that hurt materials.

Keep Dry: Use grease to keep water away from parts.

As said in Wiring Harness News, taking care and installing right helps car connectors work well always. Following these tips makes sure your car's electric systems last long and work great.

Why Good Connectors Matter

Good car connectors are important for how cars work and stay safe. Good car connectors make sure everything connects well, which helps the car's electric parts run smoothly.

How They Affect Car Work

Being Reliable

Reliable connectors help electric signals and power move easily between parts. This is key for keeping things like the engine, lights, and music systems working right. If connectors break, it can mess up these systems and hurt how the car works. For example, a bad connector in the engine can stop good communication with sensors, making the engine run poorly.

Keeping Safe

Safety is super important in car design, and connectors help a lot here. Good connectors lower the chance of electric problems that could cause danger like shorts or fires. By keeping connections strong and safe, they help protect safety features like airbags and brakes. As said in The Essential Guide to Auto Electrical Connectors, using good connectors makes cars safer by ensuring solid connections.

Costs Over Time

Cost to Replace

Buying good connectors saves money on replacements later. Bad ones wear out fast and need changing often. This raises costs for fixing them and paying workers. Picking tough connectors means fewer changes needed, saving money in the end.

Cost of Downtime

When cars stop working because of bad connectors, it costs owners time and money. Repairs mean lost work time or business income. Good connectors cut down surprise breakdowns so cars keep running well. As shown in Auto Connectors and Vehicle Performance, choosing right helps cars last longer with less downtime cost.

Brand Picks and Buying Tips

Picking the right brand for car connectors is important. It makes sure they work well. Here are some top brands known for good quality.

Best Brands Available

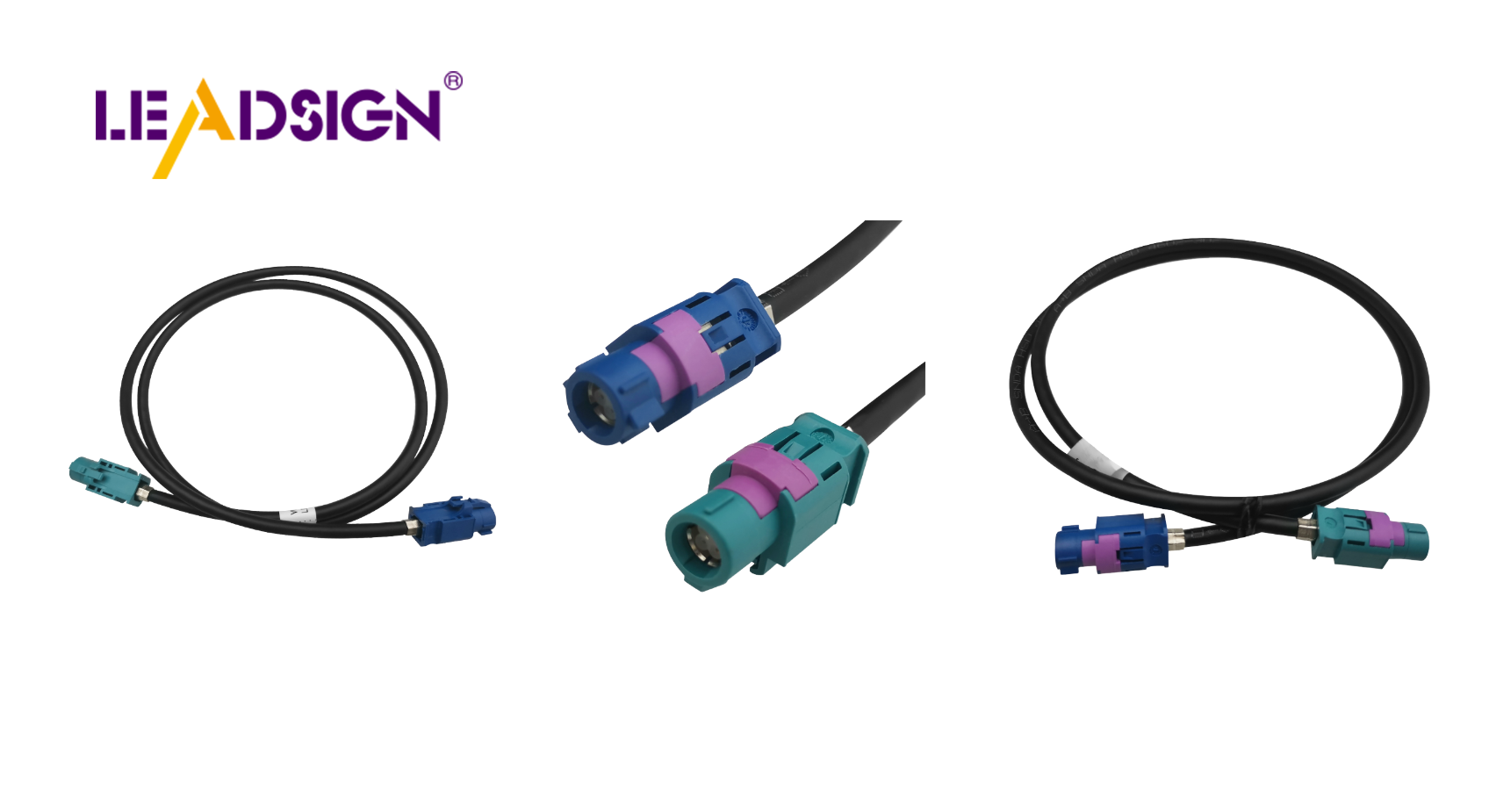

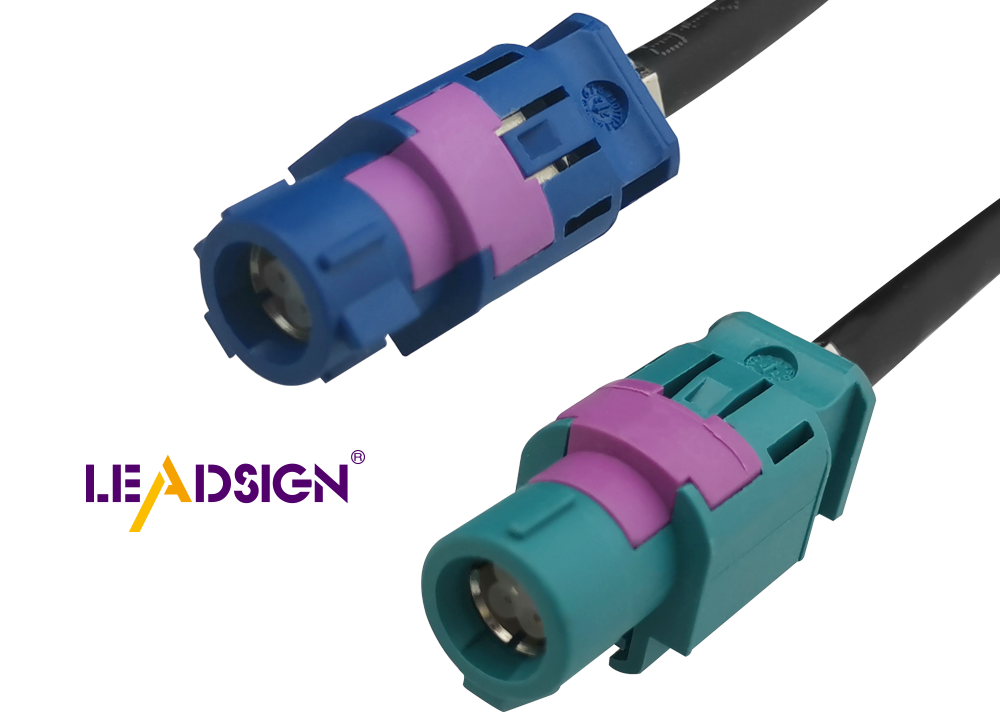

LEADSIGN

LEADSIGN makes fast data connectors, like the HSD Connector. These are made for car electronics, helping with things like USB and infotainment systems. LEADSIGN's connectors hold cables tight and work efficiently, making them a good pick for new cars.

TE Connectivity

TE Connectivity is a big name in connectors, known for smart solutions and many products. They have over 500,000 items used in cars, planes, and networks. Their connectors last long and handle tough conditions well.

Amphenol

Amphenol is also a key player in car connectors. Their high-quality products are trusted for tough car jobs. Amphenol's connectors meet strict car standards to work well over time.

Where to Shop

Finding the right place to buy car connectors is key to getting real products at good prices. Here are some places to try:

Online Stores

Online sites make buying easy. Websites like Amazon and eBay offer many choices from different brands. They have reviews that help buyers choose wisely. Plus, online stores often have good prices and sales.

Local Car Parts Shops

Local shops are great for buying connectors quickly. You can see the product before you buy it at places like AutoZone or NAPA Auto Parts. They sell trusted brands so you know you're getting quality stuff.

By looking at these brand picks and shopping tips, people can choose the best car connectors easily. This helps make sure their chosen parts fit their cars' needs well.

Learning about car electrical connectors is key for keeping cars working and safe. This guide talked about different types, uses, and how to pick them. Knowing about connectors helps make sure they work well. It's important to choose ones that fit and are good quality. Good connectors make cars last longer and stay safe. Having the same kind everywhere makes things work together easily. Using strong connectors stops expensive fixes and wasted time. Picking the right connectors helps cars run their best and stay safe.

See Also

Navigating Ford Fakra Connectors

Essential HSD Connectors in Automotive Sector

Significance of Fakra Connectors in Contemporary Vehicles