The Role of Collaboration in Advancing Types of Wire Connectors Automotive

Working together is key to improving High-Speed Automotive Connectors. Cars are changing with new systems and self-driving technology. This creates a big need for better solutions quickly. Making connectors smaller, faster, and safer is very important now. For instance, the car connectors market might grow by 8.53% yearly from 2024 to 2032. This shows how much the industry values new ideas. Fast High-Speed Automotive Connectors lead this change, helping new features work well in today's cars.

Key Takeaways

Collaboration among designers and manufacturers is crucial for developing innovative automotive wire connectors that meet the demands of modern vehicles.

High-speed connectors, like HSFM and Rosenberger FAKRA-Mini, enable fast data transmission essential for advanced features such as self-driving and safety systems.

Miniaturization of connectors allows for more efficient use of space in vehicles, accommodating the growing number of features without compromising performance.

Safety features like Connector Position Assurance (CPA) enhance the reliability of connectors, ensuring secure connections in critical systems.

Automotive connectors must withstand harsh conditions, making durability a key factor in their design and selection.

Future trends in automotive connectors emphasize flexibility, affordability, and the use of smaller components to support eco-friendly and advanced technologies.

Early teamwork in the design process can lead to quicker problem-solving and faster implementation of new technologies in the automotive industry.

The Importance of Automotive Wire Connectors

The Role of Wire Connectors in Modern Vehicles

Helping sensors, control units, and systems work together.

Wire connectors are important for making car systems work well. They help sensors, control units, and electronics share information. For example, when you use GPS or parking sensors, connectors send data between parts. Without good connectors, these systems wouldn’t work properly.

Today’s cars need connectors that send data very fast. Old connectors focused on strength and power. New ones focus on smooth communication. This change helps complex car systems work together better.

Making advanced features like self-driving and safety systems possible.

Wire connectors make new car technologies work. Self-driving and safety systems need fast and accurate data sharing. For example, radar and LiDAR sensors use connectors to send real-time data to the car’s brain. This helps the car make quick, safe decisions.

Connectors also help with systems like fleet tracking and telematics. These need fast data sharing and strong links to outside networks. Connectors connect inside and outside systems, making advanced features work smoothly.

Challenges in Developing Automotive Wire Connectors

Making small connectors that still work well and last long.

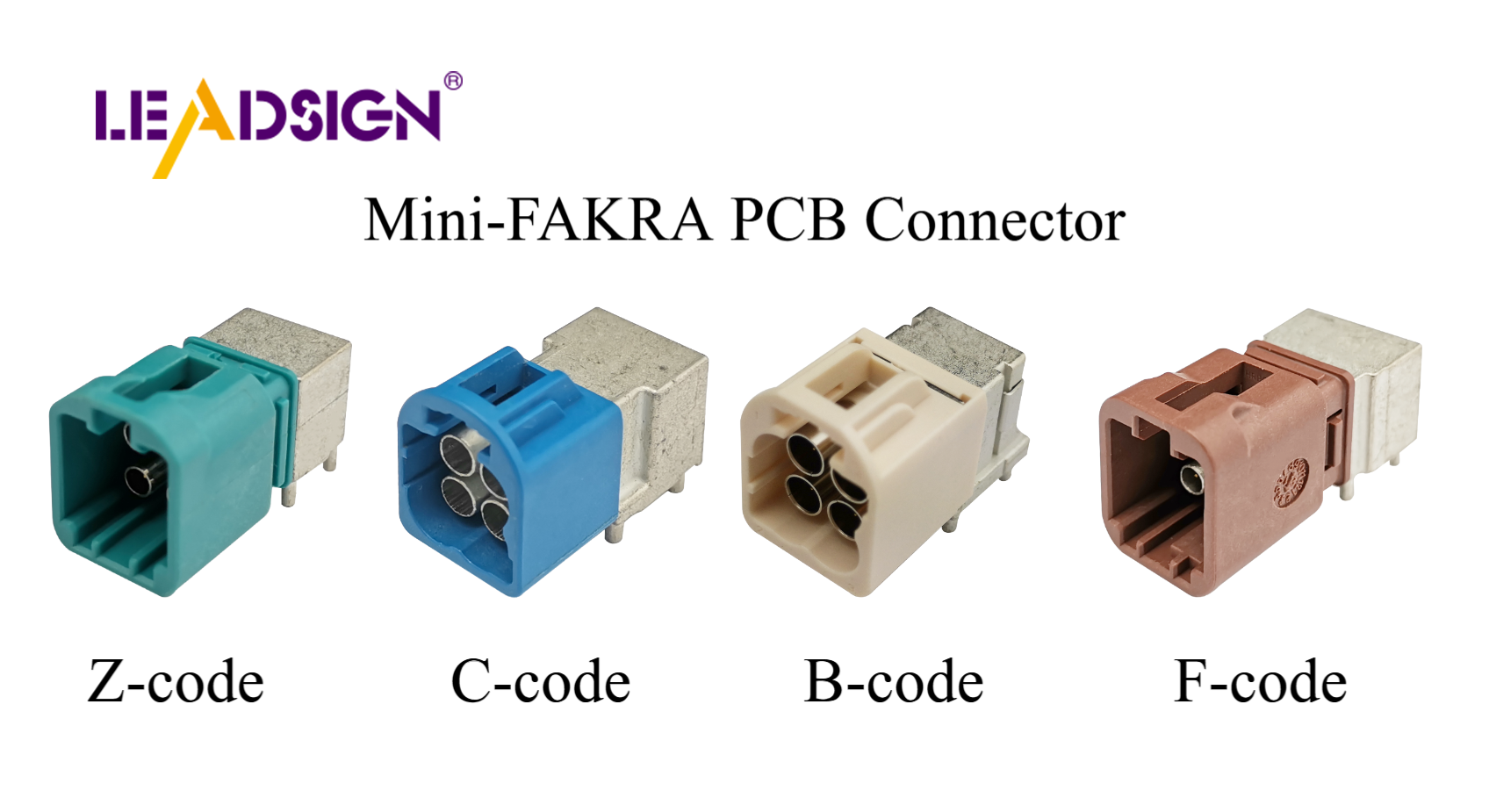

Cars are getting smaller but have more features. This means parts need to fit in tight spaces. Smaller connectors, like High-Speed FAKRA-Mini, save space. They take up 80% less room than older connectors. This helps car makers use space better without losing function.

But small size can’t mean less strength. Connectors must handle tough conditions like heat and shaking. Designers use new ideas and materials to make small, strong connectors.

Handling fast data and meeting safety rules.

Fast data sharing is key for today’s cars. Systems like GPS and safety features need connectors that send lots of data quickly. For example, HFM connectors send data at 28 Gbps. This helps cars use features like self-driving safely.

Safety rules make things harder. Connectors must meet strict standards to work in all conditions. Features like Connector Position Assurance (CPA) ensure secure links in key systems. By doing this, connectors improve performance and keep drivers safe.

"New connector technology will help the market grow. It will provide strong and efficient connectors for tough car environments.

Collaborative Innovations in High-Speed Automotive Connectors

Miniaturization and Space Optimization

Switching from FAKRA to Mini Koax for saving space and weight.

Modern cars need smaller, better parts. Old FAKRA connectors take up too much room. Mini Koax connectors solve this problem. They are smaller and lighter, perfect for tight car designs. With Mini Koax, makers can fit more parts in small spaces without losing quality.

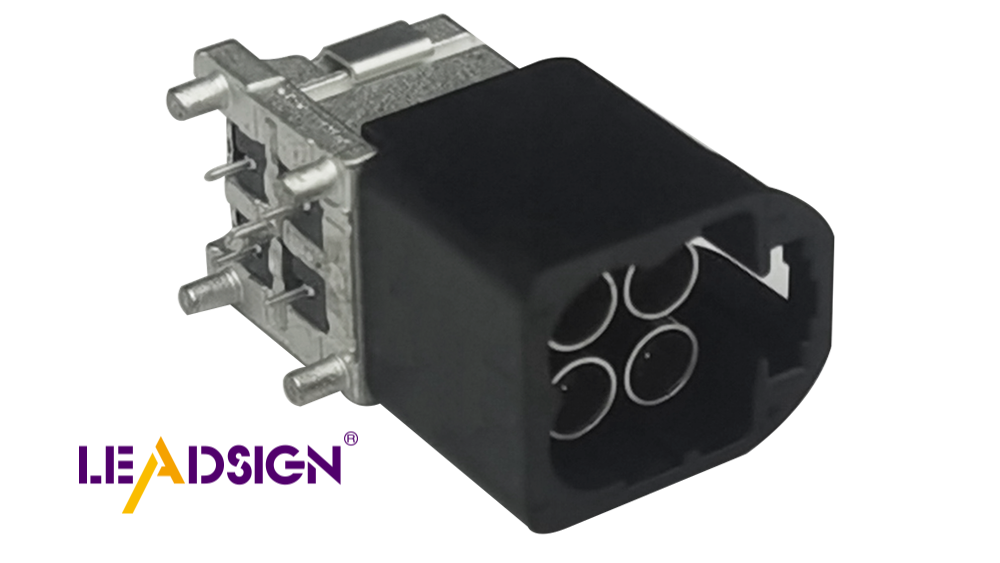

HSFM connectors cutting PCB size by nearly half.

Saving space is very important in car designs. HSFM (High-Speed Fakra Mini) Connectors are great for this. They make PCB layouts 48% smaller. This is helpful in cars where space is limited. HSFM connectors allow compact designs that work better overall.

High-Speed Data Transmission

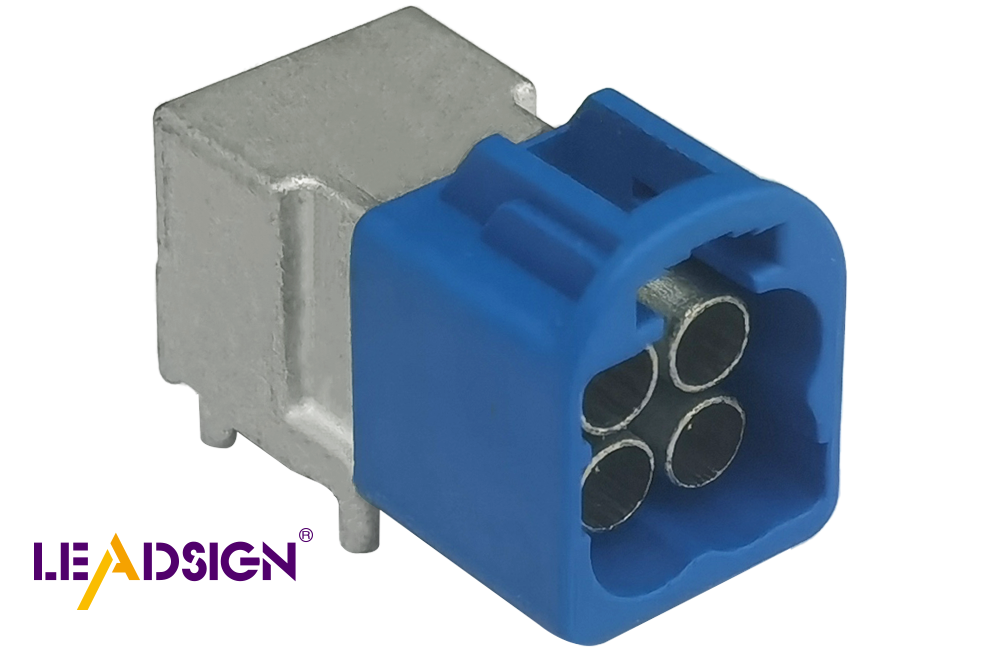

HSFM Series handling up to 20 GHz for radars and LiDAR.

Fast data sharing is key for modern car systems. The HSFM Series can handle speeds up to 20 GHz. This makes them perfect for radars and LiDAR. These systems need quick data to work well. HSFM connectors help parts talk to each other, making self-driving and safety features possible.

Rosenberger High-Speed FAKRA-Mini reaching speeds of 28 Gbps.

For even faster data, Rosenberger High-Speed FAKRA-Mini Connectors are the best. They send data at 28 Gbps, which is very fast. They also save 80% of space compared to older connectors. This mix of speed and small size is great for today’s cars with advanced computers and entertainment systems.

Enhancing Safety and Reliability

CPA ensuring secure links in systems like autopilot.

Safety is very important in cars. Connector Position Assurance (CPA) keeps connections secure in systems like autopilot. CPA stops accidental disconnections, keeping systems safe. Adding CPA to connectors makes sure they work well in all conditions.

Meeting strict rules for strong and reliable connectors.

Car connectors must follow tough rules to stay reliable. High-speed connectors like HSFM and Rosenberger FAKRA-Mini meet these rules. They can handle heat, cold, and shaking. Choosing these connectors means your car will have strong and lasting parts.

Real-World Examples of Collaborative Success

HSFM Series and Mini Koax Systems

Small designs improving PCB layouts and car networks.

Teamwork helps create HSFM Series and Mini Koax systems. These connectors are small and improve PCB layouts in cars. By making parts smaller, engineers build better car networks. This saves space and uses every part of the car well.

For example, the HSFM Series makes PCB sizes 48% smaller. This gives a neat design without losing quality. Mini Koax connectors are also small and light. They fit perfectly in tight spaces of modern cars.

Used in radars, cameras, and navigation systems.

These connectors are important for many car features. They are used in radars, cameras, and navigation systems. Radars need them to send signals for detecting objects. Cameras use them to show live video for safety. Navigation systems depend on them for accurate location data.

By using HSFM and Mini Koax, car makers ensure these features work well. Designers and engineers work together to make connectors for today’s cars.

Automotive Ethernet and High-Performance Computers

Modular housings saving up to half the space.

Automotive Ethernet and computers use modular housings to save space. These housings take up 50% less room, leaving space for other parts. Their design makes assembly easier and fits different car setups.

For example, modular housings combine many connectors into one unit. This reduces mess and improves system efficiency. This design saves space and keeps connections strong in tough conditions.

Handling data speeds from 100 Mbit/s to 50 Gbit/s.

These connectors are great for fast data sharing. They handle speeds from 100 Mbit/s to 50 Gbit/s. This helps cars manage the large data needed for advanced features.

Fast data sharing connects systems like entertainment and driver assistance. It streams videos or processes real-time driving data smoothly. These connectors show how teamwork creates amazing car technology.

The Future of Automotive Wire Connectors

Trends Shaping Future Developments

Using smaller parts in car designs.

Car makers are using smaller parts to save space. Tiny connectors, like the HFM® series, help fit more features in cars. These connectors save room but still work very well. They are important for modern car designs.

Smaller parts also help combine complex systems like self-driving and ADAS. Using tiny components makes cars lighter and saves energy. This change improves how cars work and supports eco-friendly goals.

Need for flexible and affordable connector systems like HFM®.

Cars now need connectors that work for many uses. Systems like HFM® are great because they are flexible and fast. They can be used for things like entertainment and safety features.

Cost is also important. Car makers want good parts that aren’t too expensive. HFM® connectors save 80% of space, cutting costs. They are high-quality and affordable, making them popular worldwide.

"Automotive Wire Harness and Connectors improve processes, cut costs, and boost efficiency." – Expert on Automotive Wire Connectors

The Importance of Teamwork

Working together early to solve problems.

Teamwork between designers and makers is very important. When they work together early, they can fix problems and make better connectors. For example, they can create special connectors for self-driving cars or fast computers.

Early teamwork also speeds up making new products. Sharing ideas and tools helps bring new technology to you faster. This way, you get the latest car features sooner.

Trying new ways to connect and build.

Innovation happens when teams try new ideas. In cars, this means finding better ways to send data quickly and reliably. Techniques like high-speed signals make connectors faster and better.

Building methods are also improving. Robots and precise tools make strong, high-quality connectors. These new methods ensure connectors last long and handle tough conditions. By trying new ideas, the industry keeps improving wire connectors.

Teamwork helps improve car wire connectors. When makers, engineers, and designers join forces, they solve problems for today’s cars. Smaller connectors fit tight spaces but still work well. Fast data sharing helps advanced features like self-driving work smoothly. Safety tools, like Connector Position Assurance, keep systems reliable.

"Car companies must work together to stay strong and handle changes."

As cars change, teamwork will stay important. By working together, we’ll see smarter, safer, and better car technology soon.

FAQ

How strong are automotive connectors?

Automotive connectors are made to survive tough conditions. They can handle heat, cold, shaking, water, and chemicals. This strength helps them work well and last long in hard environments.

What do automotive connectors do?

Automotive connectors join parts in your car. They help systems like sensors and control units share information. These connectors keep your car safe and working properly.

Why are smaller connectors important?

Smaller connectors fit into tight spaces in modern cars. High-Speed FAKRA-Mini connectors save 80% of space compared to older ones. This lets car makers add more features without losing quality.

How do connectors send data quickly?

Modern connectors, like the HSFM Series, send data very fast. They can handle speeds up to 28 Gbps. This helps systems like radars and infotainment work smoothly in real-time.

What makes connectors safe for critical systems?

Features like Connector Position Assurance (CPA) make connectors reliable. CPA keeps connections secure, stopping accidental disconnections in systems like autopilot. This is important for car safety.

Can connectors handle tough environments?

Yes, automotive connectors are built for harsh conditions. They resist heat, cold, and shaking. This makes them perfect for systems like navigation and driver assistance.

How do modular housings help car designs?

Modular housings save space and make assembly easier. They cut component size by 50%, fitting well in small car designs. They also combine connectors, improving system efficiency.

Why is teamwork important for making connectors?

Teamwork between makers and designers leads to better connectors. By working together, they create solutions for modern cars, like smaller sizes and faster data sharing.

Why do self-driving cars need fast connectors?

Self-driving cars need quick and accurate data sharing. High-speed connectors, like Rosenberger FAKRA-Mini, send real-time data between sensors and control units. This helps cars make safe decisions.

What trends are shaping future connectors?

Future connectors focus on being small, flexible, and affordable. Systems like HFM® save space but still work well. These trends help add advanced features like self-driving and eco-friendly tech.

See Also

Why Fakra Connectors Matter in Today's Automotive Sector

Key Role of HSD Connectors in Automotive Applications

Benefits of HFM Connectors for Modern Automotive Design

Transforming Vehicle Connectivity with HFM Connector Benefits