A Guide to Cleaning and Replacing Automotive Plugs and Connectors

Taking care of automotive plugs and connectors is very important. They help send power and information to different parts of the car. Dirt, water, and damage can make them stop working well. This can cause electrical problems or system breakdowns. Cleaning them often and replacing them when needed avoids these issues. It also makes your car more reliable. By maintaining these parts, your car works better and lasts longer. This saves you time and money over time.

Key Takeaways

Regularly clean automotive plugs and connectors to prevent dirt and rust buildup, which can lead to electrical issues.

Use the right tools, such as compressed air and specialized contact cleaners, to ensure effective and safe cleaning.

Inspect connectors for damage like corrosion or bent pins before cleaning or replacing them to avoid further complications.

When replacing connectors, choose high-quality, weatherproof options to enhance durability and performance in harsh conditions.

Follow a step-by-step process for both cleaning and replacing connectors to ensure proper handling and secure connections.

Implement preventive maintenance by checking connectors every few months to catch potential problems early and save on costly repairs.

Utilize protective measures like dielectric grease and heat shrink tubing to extend the life of your connectors and prevent future damage.

Cleaning Automotive Plugs and Connectors

Keeping automotive plugs and connectors clean is very important. Dirt and water can build up and cause bad connections. This might lead to electrical problems in your car. Cleaning them the right way helps them last longer. It also saves you money by avoiding expensive repairs.

Tools and Materials for Electrical Connector Maintenance

To clean automotive plugs and connectors, you need proper tools. Here are the basics:

Compressed Air: Blows away dirt from small, hard-to-reach spots.

Soft-bristled Brush: Cleans grime gently without harming the contacts.

Lint-free Cloth: Wipes surfaces clean without leaving fibers behind.

Alcohol Swab: Removes grease and kills germs on the connectors.

Specialized Contact Cleaner: Made for electrical connectors, it cleans and stops rust.

Terminal Cleaning Tool Kit: Includes tools for cleaning connector terminals easily.

These tools help clean well and protect delicate parts.

Step-by-Step Guide to Cleaning Connectors

Follow these steps to clean automotive plugs and connectors:

Disconnect the Connector: Turn off the car and unplug carefully to avoid damage.

Inspect the Connector: Look for dirt, rust, or damage. Replace if rust is bad.

Remove Loose Debris: Use compressed air to blow away dust and dirt.

Apply the Cleaner: Spray contact cleaner to remove grime and stop rust.

Scrub Gently: Use a soft brush or swab to clean lightly. Don’t press hard.

Wipe Dry: Dry with a lint-free cloth. Make sure no water is left.

Reassemble the Connector: Once dry, plug it back in securely.

Clean every few months to keep them working well.

Common Mistakes to Avoid When Cleaning Connectors

Avoid these mistakes when cleaning automotive plugs and connectors:

Using Harsh Tools: Don’t use rough brushes or metal tools that scratch.

Skipping Inspection: Always check for damage before cleaning.

Overusing Cleaner: Too much cleaner can leave sticky residue.

Neglecting Drying: Wet connectors can rust and stop working.

Applying Excessive Force: Clean gently to avoid breaking the contacts.

Avoiding these mistakes helps your connectors last longer and work better.

Replacing Automotive Plugs and Connectors

Changing damaged automotive plugs and connectors keeps your car running well. Broken connectors can stop power flow, causing problems or safety risks. Finding issues early and replacing them correctly helps your car stay reliable.

Identifying Damaged Connectors

Damaged connectors often look worn out. Check for corrosion, bent pins, or melted plastic. Corrosion weakens connections and can cause overheating. Cracked or loose covers also show damage. Flickering lights or power loss may mean bad connectors. Inspect them right away if you notice these signs.

"Power connectors are key parts that keep systems working properly. Over time, wear can harm their performance and increase resistance."

To check the problem, unplug the power and use a multimeter. This tool tests for voltage drops and connection issues. If the connector fails, replace it.

Choosing the Right Replacement Connector

Picking the right connector is important for a strong connection. Match the new one to the old in size and type. For newer cars, try weatherproof designs. These block dirt and water, lasting longer in tough conditions.

When fixing a wiring harness, you might need a butt connector or pigtail connector. Butt connectors join two wires tightly. Pigtail connectors let you add one wire to the harness. Always pick good-quality connectors to avoid future problems.

Step-by-Step Guide to Replacing Connectors

Here’s how to replace damaged connectors:

Disconnect the Power Source: Turn off the car and unplug the battery for safety.

Remove the Damaged Connector: Use a tool to take out the connector without breaking wires.

Prepare the Wires: Strip off some insulation. Make sure the wire is clean.

Attach the New Connector: Use a butt connector or pigtail connector to connect wires. Crimp it tightly.

Seal the Connection: For weatherproof electrical connectors, cover with heat shrink tubing or tape to block dirt and water.

Test the Connection: Plug the power back in and test to ensure it works.

Replacing connectors may seem hard, but these steps make it easier. Checking and replacing them on time avoids bigger problems and saves money.

Tips for a Successful Replacement

Replacing automotive plugs and connectors needs care and accuracy. These tips help make strong, lasting connections:

Pick Good Connectors

Use connectors made from strong materials. Good connectors last longer and work better. For tough conditions, choose weatherproof connectors to keep out water and dirt.Check Wires Carefully

Look at wires before adding a new connector. Check for broken or rusty parts. Bad wires can weaken the connection. Cut and clean wires if needed for a better fit.Use the Right Tools

Get tools like wire cutters, crimpers, and heat guns. These tools make neat connections without harming wires. Don’t use random tools, as they can mess things up.Crimp Securely

Press crimp connectors firmly but not too hard. Loose crimps can fail, and tight ones can break wires. Tug the wire gently to check if it’s secure.Seal the Connection Well

Cover the connection with heat shrink tubing or tape. This keeps out dirt and water, stopping rust or short circuits.Test the Connection

After replacing, test to see if it works. Use a multimeter to check voltage and flow. Testing finds problems before putting everything back together.

"Power connectors are key parts that keep systems working properly."

Bad or loose connectors can cause overheating or failures. Replacing them right avoids these problems.

Follow Instructions

Read the car or connector maker’s guide for steps. These guides give tips on fitting and matching parts.

By using these tips, you can replace connectors well. Fixed connectors improve your car’s safety and performance. They also help your car’s electrical system last longer.

Preventive Maintenance for Automotive Plugs and Connectors

Taking care of automotive plugs and connectors is very important. Regular checks and cleaning keep them working well. This also helps avoid expensive repairs later.

Why Regular Maintenance Matters

Checking plugs and connectors often helps find problems early. Dirt and water can build up over time. This can cause bad connections or even make them stop working. Look for rust or damage during inspections. Green or white spots on metal mean corrosion. Corrosion makes connections weak and blocks electricity flow. Clean them often and use dielectric grease to stop rust. Check these parts every few months or when fixing other car parts.

Pro Tip: "Looking at connectors often can stop big problems later."

Protecting Connectors from Damage

Using protective items keeps connectors safe from harm. Dirt, water, and heat can ruin them. The right materials help them last longer.

Dielectric Grease: Stops water and rust while helping electricity flow better.

Heat Shrink Tubing: Covers wires to block dirt and water.

Weatherproof Connectors: Stronger connectors for tough weather.

Protective Caps: Keep unused connectors clean and safe.

These tools protect connectors and stop damage from the environment.

Stopping Common Connector Problems

Knowing what harms connectors helps you prevent damage. Many problems happen because of bad handling or ignoring care. Here’s how to avoid them:

Pulling Wires Wrong

Don’t pull wires to unplug. Hold the connector instead.Water Damage

Water causes rust and short circuits. Use weatherproof connectors to block water.Overheating

Loose connectors can get too hot and melt. Make sure they are tight.Skipping Cleaning

Dirt can ruin connections. Clean them with contact cleaner often.Using Cheap Connectors

Low-quality connectors break faster. Use good ones made for cars.

Fixing these issues keeps connectors working well for a long time.

Remember: "Caring for connectors now saves money and trouble later.

Taking care of car plugs and connectors is very important. Cleaning them often stops dirt and rust from causing problems. Changing broken connectors keeps your car safe and working well. Follow these steps to avoid expensive fixes and make your car last longer. Check, clean, and replace them when needed. A small effort now saves money and keeps your car running great later.

FAQ

What are automotive plugs and connectors?

Automotive plugs and connectors link your car's electrical systems. They move power and data between parts to keep things working. These are important for lights, sensors, and entertainment systems.

"Power connectors are key for stable and correct system operation."

Why is it important to maintain automotive connectors?

Taking care of connectors stops power loss and keeps systems working. Dirt or damage can break connections and cause failures. Regular care helps them last longer and avoids costly repairs.

"Good connector care ensures better performance and longer life."

How often should I clean my automotive connectors?

Clean your connectors every few months or during car check-ups. Cleaning removes dirt and water, stopping rust. If lights flicker or power fails, check and clean them right away.

What tools do I need to clean automotive connectors?

To clean connectors, you need:

Compressed air to blow away dirt.

Contact cleaner to clean and stop rust.

Soft-bristled brush for gentle cleaning.

Lint-free cloth to dry them.

These tools clean well without harming parts.

How do I know if a connector needs replacement?

Look for damage like rust, bent pins, or melted plastic. Flickering lights or power loss may mean bad connectors. Use a multimeter to check voltage. Replace worn or broken connectors.

What are the benefits of using advanced connectors?

Advanced connectors fit better and lock securely. They stop power loss and work reliably. These are great for modern cars with smart systems and electric features.

"New connectors improve how vehicles work and stay reliable."

Can I replace a damaged connector myself?

Yes, you can replace a connector by following these steps:

Turn off the power.

Take out the broken connector carefully.

Strip the wire insulation.

Attach the new connector tightly.

Cover it with heat shrink tubing.

Test to make sure it works.

Using proper tools makes the job easier.

What are weatherproof connectors, and why should I use them?

Weatherproof connectors block water, dirt, and heat. They work well in tough conditions and last longer. These connectors stop rust and protect your car’s electrical system.

How can I protect connectors from damage?

Protect connectors by:

Adding dielectric grease to stop rust and water.

Using heat shrink tubing to seal wires.

Putting protective caps on unused connectors.

Handling them gently during repairs.

These steps keep connectors safe and working well.

Are metal connectors better than plastic ones?

Metal connectors are stronger and last longer with care. They handle tough conditions better. Plastic ones are lighter but less durable. Pick based on your car’s needs and environment.

"Metal connectors last long and handle tough use with care."

See Also

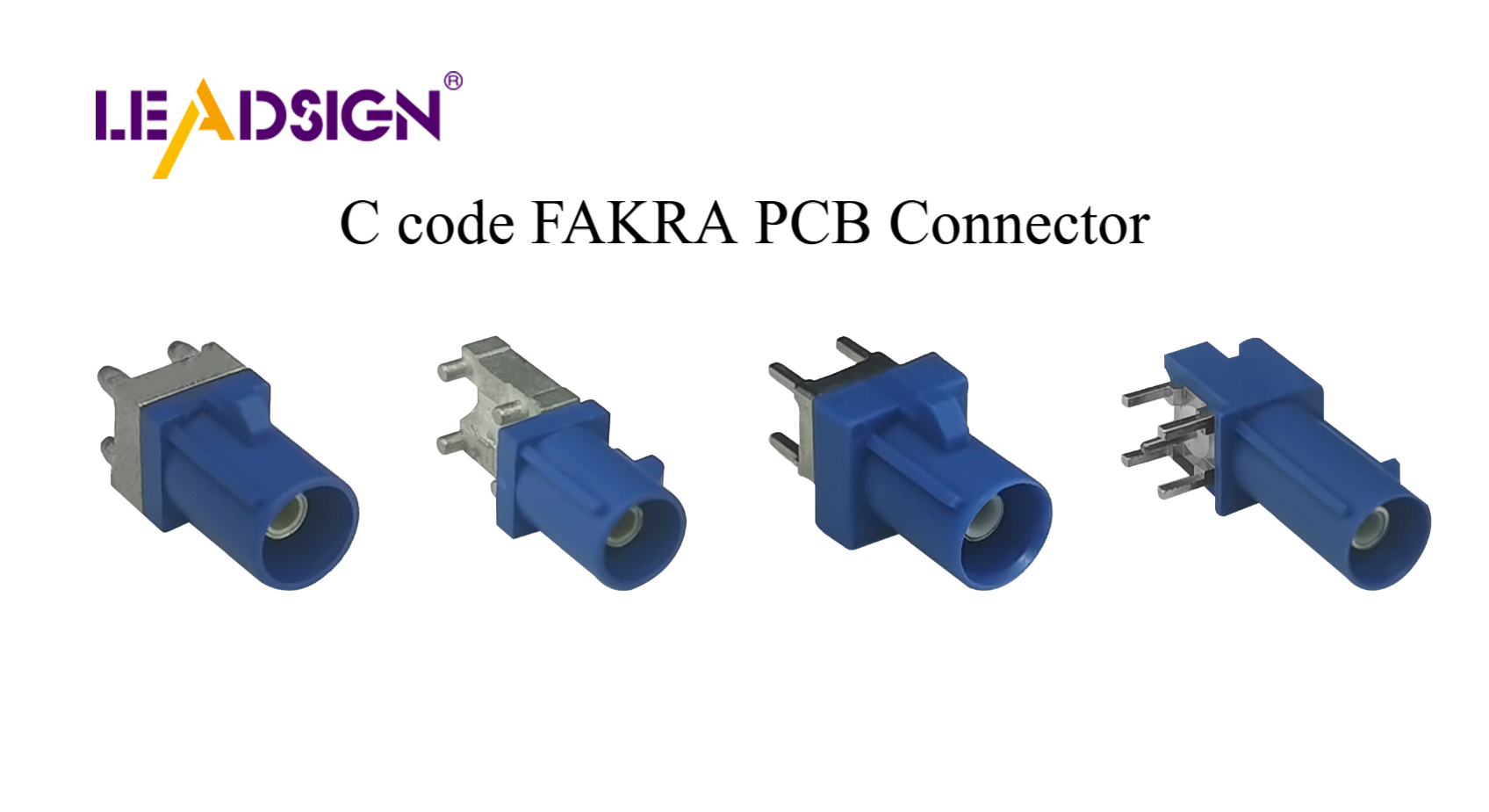

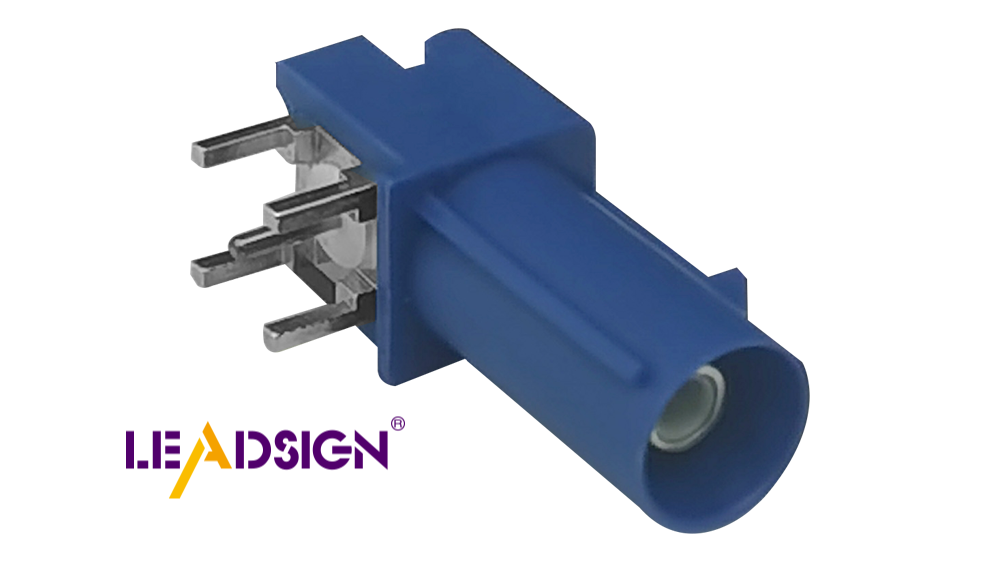

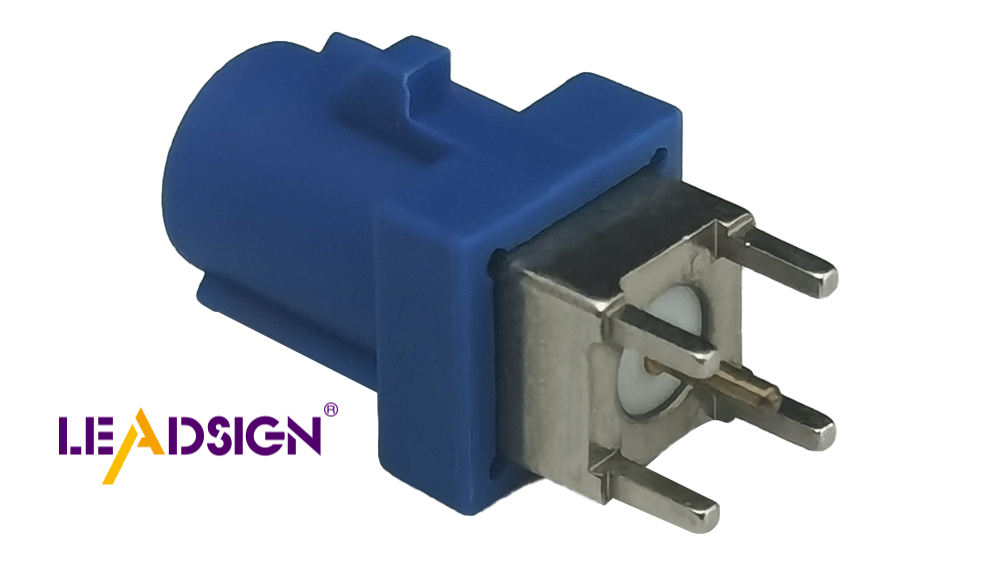

Exploring Ford Fakra Connectors: A Complete Overview

Why Fakra Connectors Matter in Today's Vehicles

Significance of FAKRA Connectors in Car Technology