How to Find the Best Vehicle Connectors for Your Automotive Network

Choosing the right wire connectors automotive type is crucial for ensuring your vehicle's network operates safely and efficiently. Using the incorrect connectors can lead to power issues or safety hazards. Consider factors such as power requirements and environmental conditions. It's essential to ensure that the connectors are compatible with your system as well. Each project has unique needs, so it's important to understand those requirements first. Explore the various types of wire connectors automotive type to identify the best fit. Making an informed choice will result in a robust, efficient, and durable network for your vehicle.

Key Takeaways

Understand your vehicle's specific power and environmental needs to choose the right connectors, ensuring safety and efficiency.

Select connectors that match the wire type and size to prevent overheating and ensure reliable connections.

Consider using sealed connectors in harsh environments to protect against water, dust, and extreme temperatures.

Look for industry certifications like UL, ISO, and SAE to ensure the connectors meet safety and quality standards.

Test connectors in small setups before full installation to catch potential issues early and ensure compatibility.

Choose connectors that are easy to maintain and have readily available replacement parts to minimize downtime.

Keep spare connectors on hand for quick repairs, ensuring your vehicle's systems remain operational without delays.

Understanding Your Vehicle's Needs

Knowing what your vehicle's system needs is important. This helps it work well and stay reliable. Below are the main things to check.

Checking Electrical Load

Picking connectors for wire size and power

Your system's power decides the connector type needed. The connector must match the wire size and power capacity. If not, wires may overheat or fail. Thicker wires need connectors for more power. Always compare wire and connector details to ensure they fit.

Setting voltage and current levels for each part

Each part of your system uses different voltage and current. Decide these levels before picking connectors. This avoids problems like losing power or short circuits. For advanced systems, use connectors made for higher voltage and current.

Thinking About Environment

Considering heat, water, and shaking

The environment affects how well connectors work. Heat can damage them, while water or shaking can loosen connections. Think about what your vehicle faces daily. For example, off-road vehicles need strong connectors due to bumps and dirt.

Using sealed connectors in tough places

Sealed connectors work best in wet or dirty areas. They keep water, dust, or chemicals out of the parts inside. Waterproof ones are great for vehicles in rainy places. These ensure safety and last a long time.

Looking at Wire Details

Knowing wire types used

The kind of wire matters when choosing a connector. Copper wires are common because they carry electricity well. Some systems use aluminum wires needing special connectors instead. Check the wire type to avoid mismatches.

Matching materials of wires and connectors

Connector materials should match with wires to stop rusting or wear-out issues. For copper wires, pick copper-based connectors too. This keeps connections strong over time. Always read material details before deciding.

By checking all these points, you’ll find the right automotive wire connectors for your project! This ensures your vehicle’s system stays safe and works smoothly.

Exploring Types of Vehicle Wire Connectors

Picking the right wire connectors helps your car work well. Different connectors have special uses and benefits. Knowing these differences helps you choose wisely.

Crimp Connectors

Why crimp connectors are strong

Crimp connectors tightly press wires together for a solid hold. This method skips soldering, making it quicker and easier. They handle shaking well, which is important in cars. Even on bumpy roads, they stay secure and safe to use.

Where crimp connectors are used

Crimp connectors are common in car wiring systems. They work great in places with lots of movement, like near engines. These also handle high power safely. You need a crimping tool to attach them properly.

Solder Connectors

Benefits of solder connections

Solder connectors make very strong and lasting bonds. Melting solder joins the wire and connector firmly together. This keeps electricity flowing smoothly and prevents rust over time.

When to pick solder connectors

Use solder connectors for projects needing exact and tough connections. They’re perfect for things like GPS or entertainment systems in cars. Soldering takes more tools and skill but lasts longer than other methods.

Push-In Connectors

Easy setup with push-in connectors

Push-in connectors are simple to use quickly. Just push the wire inside, and it locks tight without tools. These save time during small fixes or easy projects.

Limits of push-in connectors

Push-in types aren’t good for shaky or high-power spots. They focus on being quick rather than super strong. Use them for indoor wiring or low-power tasks where speed matters most.

By learning about each type of connector, you can decide what works best for your project needs.

Specialty Connectors

Specialty connectors are made for advanced car systems. They work well in tough conditions and with high-tech features.

Waterproof and Weatherproof Connectors

Waterproof and weatherproof connectors keep water, dust, and dirt out. These are important for cars in rough places like off-road or near water.

Key Features:

Sealed designs block water and dirt.

Strong materials stop rust and damage.

Work well in very hot or cold weather.

For example, sealed connectors help cars in rainy or snowy areas. They last long and prevent electrical problems from bad weather.

Think about your car's daily conditions when picking these connectors. This helps you choose ones that protect best and last longer.

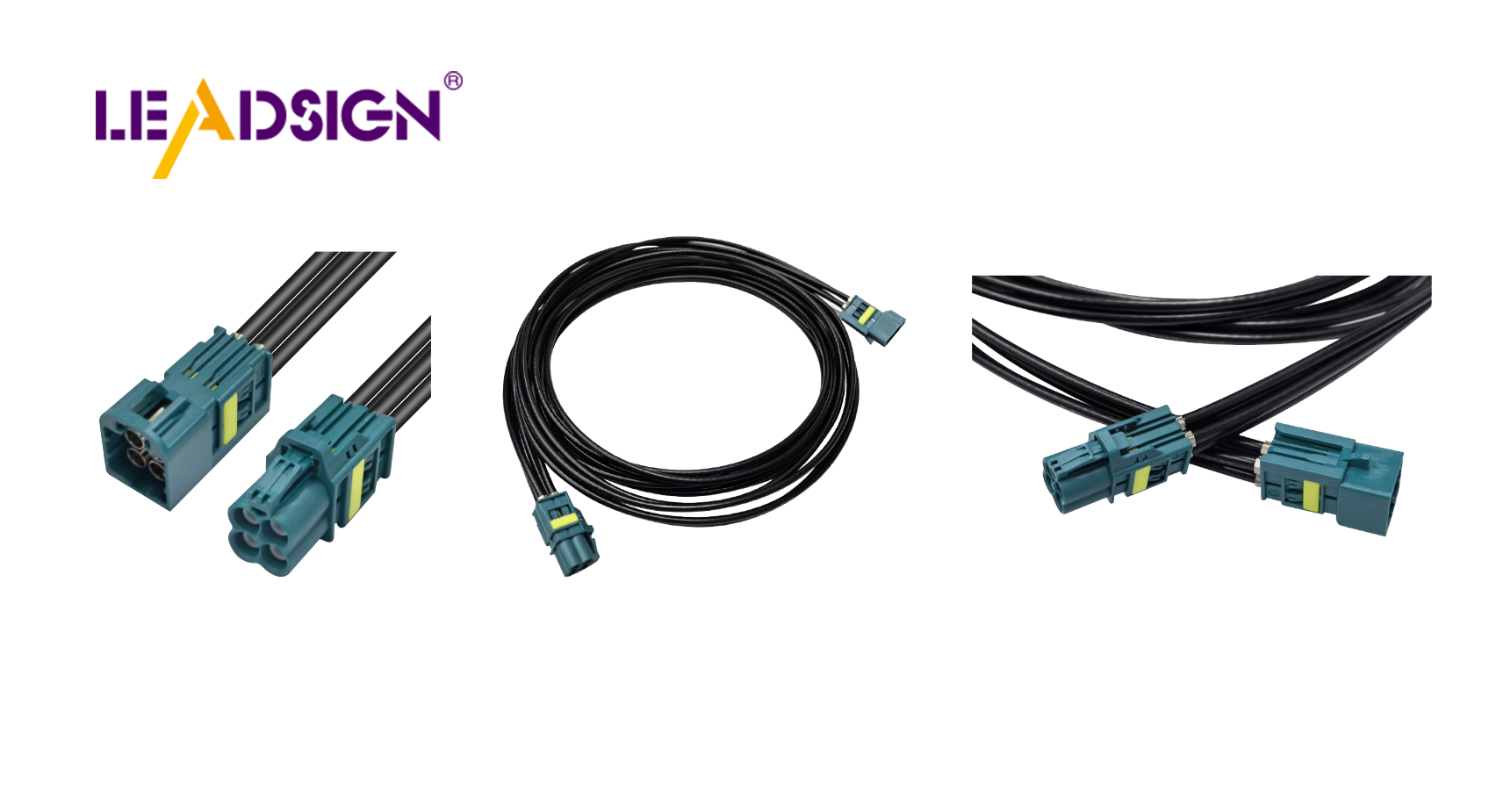

High-Performance Connectors like HFM for Advanced Systems

High-performance connectors, such as HFM (High-Speed FAKRA-Mini), are made for modern car technology. They send data fast, perfect for new systems in vehicles.

Advantages of HFM Connectors:

Small size saves a lot of space.

Sends data up to 28 Gbps quickly.

Strong design works even with lots of shaking.

HFM connectors are used in self-driving cars, driver aids, and entertainment systems. They handle high frequencies up to 20 GHz easily for smooth data flow.

For projects needing advanced systems, pick connectors like HFM. Their smart design keeps your system working well without problems.

By learning about specialty connectors, you can make better choices for your car setup. Whether it’s protection from rough weather or support for modern tech, these connectors solve your needs perfectly.

Checking Quality and Standards

Looking for Industry Certifications

Why UL, ISO, and SAE certifications matter

Certifications like UL, ISO, and SAE show that connectors are safe. These labels mean the product passed tough tests for quality. Certified connectors work well with car systems and are reliable.

For example, UL-certified ones prevent fires, while ISO checks quality. SAE ensures they meet car-specific rules.

Always check for these certifications before buying. They prove the connector is safe and long-lasting.

Following automotive standards

Car standards make sure connectors handle tough conditions. These include vibrations, heat changes, and water exposure. Picking connectors with these labels lowers failure risks. Look for "automotive-grade" on products to match your car's needs.

Checking Strength and Reliability

Using materials that fight rust and damage

Good materials help connectors last longer in harsh places. Strong ones use rust-proof metals or special coatings to stay durable. For example, nickel or gold-plated parts stop rust while keeping good electricity flow.

Durable materials protect against water, dirt, or extreme weather without breaking down.

Pick connectors built for tough car environments to avoid problems later.

Testing how long they last

Reliable connectors go through many tests to prove their strength over time. Tests check how well they handle stress, power flow, and rough conditions. For instance, High Voltage High Current Connectors are made for heavy-duty systems in cars.

Tested products give confidence since they’re less likely to fail when needed most.

Ask sellers about testing details before choosing a connector. This helps you pick wisely.

Knowing About Manufacturers

Why trusted brands matter

Famous brands often make better products you can trust. They spend money on research to improve designs and follow strict rules too.

Big brands share clear details about their products so you know what you're getting.

Stick with known names to get good-quality connectors without risks.

Reading reviews or asking others

Reviews from buyers tell you how well a product works in real life. Experts’ advice also points out which options are dependable.

If a connector gets great feedback for lasting long or being easy to install, it’s worth considering.

Take time to read reviews or ask around before buying anything.

Tips for Choosing the Right Connector

Narrowing Your Choices

Matching connectors to project needs

Start by listing what your project requires. Think about power, environment, and wire type. Match these needs with connector features. For high-power systems, pick connectors for strong voltage and current. If your vehicle faces tough weather, choose sealed or waterproof types.

Comparing features helps you find the best fit easily.

Group options into categories based on how well they match your project. This makes choosing simpler and keeps focus on the best ones.

Balancing price with quality

Don’t pick cheap connectors that might break quickly. Poor-quality ones can cause expensive repairs later. Good connectors last longer and work better over time.

Spending more now saves money by avoiding future problems.

Compare prices of trusted brands to get good value. Find connectors that balance cost, durability, and performance.

Testing Before Using Fully

Trying small tests first

Before using a connector fully, test it in a small setup. Check if it fits well and handles power safely under normal conditions.

Small tests catch problems early before they become big issues.

See how the connector works with other parts of your system. Make sure there are no loose wires or mismatches.

Installing correctly for smooth use

Follow instructions when installing connectors to avoid mistakes. Use proper tools to secure them tightly in place. Test everything after installation to ensure it works right.

A good installation prevents failures and keeps things running smoothly.

Check for overheating or loose wires during testing. Fix any issues immediately to stop future trouble.

Planning Maintenance Ahead

Picking easy-to-fix connectors

Choose connectors that are simple to repair or replace later. Look for designs with easy locks or modular parts that don’t need special tools.

Easy maintenance saves time and effort during repairs.

Make sure replacement parts are available from reliable brands too.

Keeping spares ready

Always have extra connectors stored safely for emergencies. This helps fix problems fast without waiting for new ones to arrive.

Spare parts reduce downtime and keep systems working well.

Check spares often to ensure they’re not damaged or rusty. Replace bad ones so backups stay reliable when needed.

Choosing the right connectors keeps your car system safe and strong. First, figure out what your system needs. Look at different connector types to find the best one. Check for quality by looking at certifications and trusted brands. Test connectors first to avoid problems later. Plan ahead by keeping extra parts for repairs.

Good connectors make your car work better and safer. The right choice helps now and gets your system ready for upgrades.

See Also

Maximizing Efficiency in Automotive Data Transfer Solutions

Boosting Automotive Data Flow with Fast Connectors

Fakra Connectors: Essential Components for Today's Vehicles

Transforming Vehicle Connectivity with HFM Connector Benefits