What to Look for in Vehicle Connectors for Optimal Performance

Choosing the right vehicle connectors is essential for keeping your car functioning optimally. Quality connectors prevent loose wires and rust, which can reduce repair costs. They also enhance your car's safety by ensuring that critical systems like brakes and airbags remain secure. Durable vehicle connectors contribute to better performance with fewer issues, ultimately saving you both time and money.

Key Takeaways

Choosing the right vehicle connectors is crucial for optimal car performance, enhancing safety, and reducing repair costs.

Always consider voltage and current limits when selecting connectors to prevent electrical failures and ensure compatibility with your car's systems.

Look for connectors with high IP ratings and durable materials to withstand harsh environmental conditions, ensuring longevity and reliability.

Electrical Needs for Car Connectors

Voltage and Current Limits

Knowing voltage and current limits is very important. These limits show how much electricity a connector can handle safely. For example, tests like AS39029 slowly increase current to find the connector's heat limit. Going over these limits can cause sparks, damage, or system problems.

Using too much voltage can cause sparks or system failure.

To prevent problems, pick connectors that fit your car's needs. Overloading connectors can cause power loss and failures. Always check the details to match your car's systems.

Matching with Car Systems

Not all connectors work the same way. Matching depends on things like power limits, weather conditions, and contact points. The table below explains key points:

Factor | Description |

|---|---|

Current limit | Make sure connectors handle the car's power needs safely. |

Voltage limit | Match voltage to avoid sparks and damage. |

Contact points | More contacts help with signals and future upgrades. |

Weather resistance | Pick connectors that handle heat, cold, and moisture. |

Strength | Choose connectors with strong locks to handle shaking. |

Wire connection type | Use proper methods like crimping for better signal flow. |

By thinking about these points, you can pick connectors that work well with your car.

Signal and Power Needs

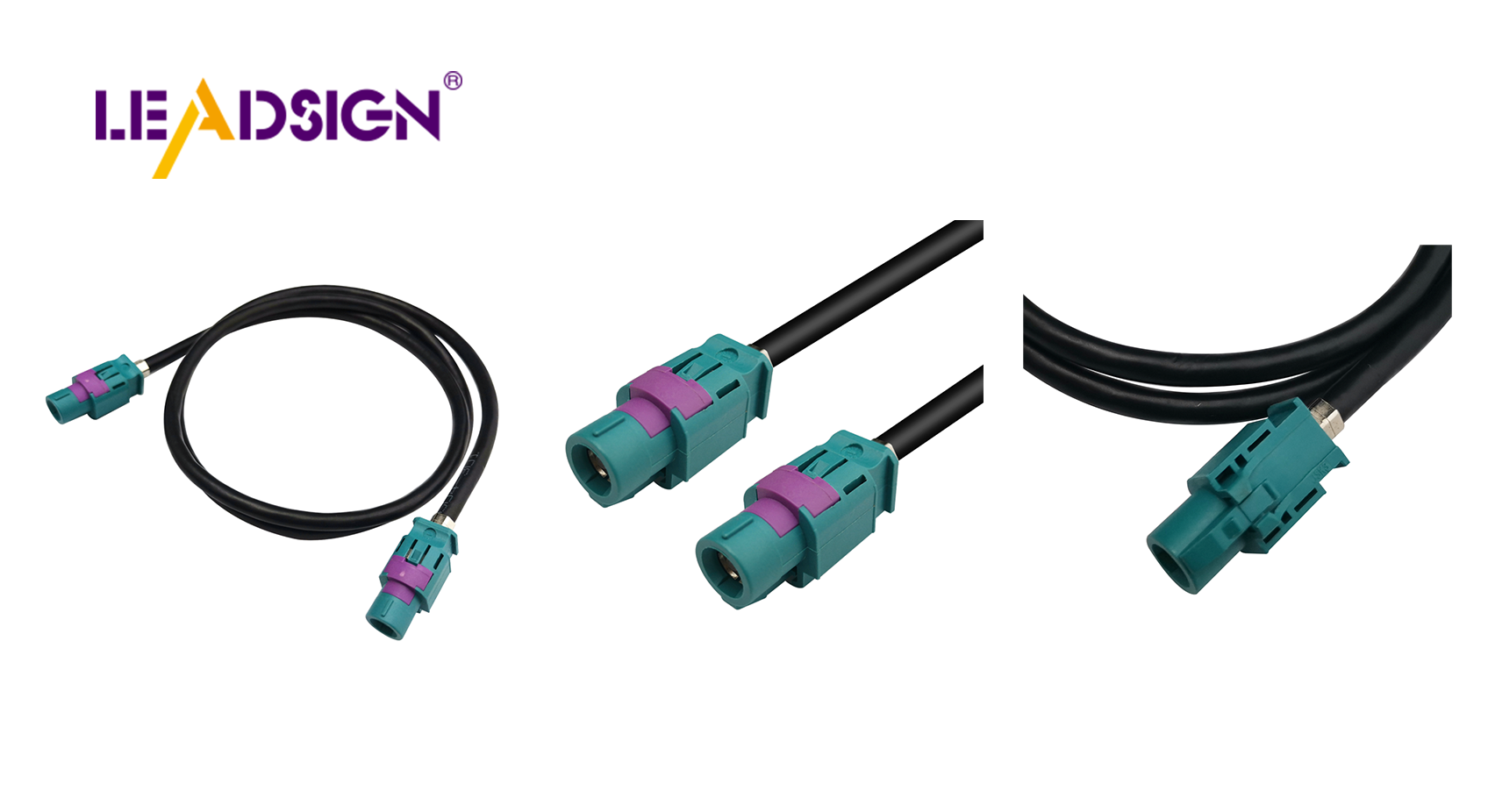

Modern cars need connectors for both signals and power. Small designs are important as cars add more electronics. Fast data connectors, like HSD ones, work well for USB, Ethernet, and entertainment systems.

When choosing connectors for signals and power, think about:

Small size to save space.

Strong performance in heat and shaking.

Ability to fit different wire sizes.

Flexibility to improve car systems.

The right connector helps deliver power and signals smoothly, keeping your car working its best.

Environmental Strength in Car Electrical Connectors

Knowing IP Ratings

IP ratings show how well connectors block dust and water. For example, an IP67 connector stops all dust and can stay underwater for 30 minutes at one meter deep. Higher numbers mean better protection.

These ratings help you choose the right connectors for your car. If your car faces wet or dusty places, pick higher-rated connectors. This keeps them working longer and better.

Handling Extreme Temperatures

Car connectors deal with very hot and cold weather. They also face bumpy roads and tough conditions. Materials like FLEXO® PFA and FLEXO® PPS work well in high heat.

Material Name | What It Does |

|---|---|

FLEXO® PFA | Handles high heat |

FLEXO® PPS | Handles high heat |

ThermaShield® Shield |

Using these materials makes connectors last in harsh weather. This is key for cars in extreme climates.

Fighting Moisture, Dust, and Rust

Water and dust can harm connectors over time. Humidity causes rust, which shortens their life. Dust wears out metal parts, making them work poorly.

To avoid this, pick connectors with tight seals and rust-proof materials. This keeps them strong and working well for a long time.

Material Quality in Choosing a Connector

Why Strong Housing Materials Matter

The material of a connector's housing affects how long it lasts. Look for connectors made from strong materials like copper or brass. These materials carry electricity well and don’t wear out quickly. They also handle tough conditions, making them great for cars.

Plastic housings with sturdy designs can protect connectors too. They keep the inside parts safe from bumps and shaking. Picking connectors with strong housing helps them last longer and work better in tough places.

Insulation and Conductivity Tips

Good insulation makes connectors safer and more efficient. Bad insulation can cause short circuits, rust, or system problems. To avoid this, choose connectors with high-quality insulation.

Good insulation stops water from causing damage.

Tight seals keep dust and water out.

Strong insulation lowers the chance of rust.

Choose connectors made for tough conditions to improve insulation. Check them often to find damage early and keep them working well.

Why Materials Affect Safety and Lifespan

Good materials make connectors safer and last longer. Strong connectors lower the chance of electrical problems in your car. High-quality materials stay strong in heat, cold, or rough use.

By choosing connectors with good housing and insulation, they will last years. This reduces repairs and keeps your car running safely and smoothly.

Connector Design Features for Best Performance

Small Size and Limited Space

Modern cars have more gadgets in small spaces. This needs tiny connectors. As more devices connect, space stays tight. Smaller connectors are now very popular in cars. For example, connector sizes have shrunk a lot over time.

Tiny connectors allow more connections in less space. They fit cables as small as 0.13mm² and still work well. This helps add more systems without losing performance. Small designs also make cars lighter and easier to fix.

Pins and Their Setup

More pins in connectors mean better connections. This lowers the chance of electrical problems. Bigger connectors with many pins are needed for complex car systems. They help with things like safety and entertainment features.

How pins are arranged also matters. Good pin setups improve signals and stop interference. This is very important for fast data systems like USB or Ethernet. Picking connectors with the right pins ensures everything works smoothly.

Locks for Strong Connections

Locks keep connectors tight, even on bumpy roads. Vibrations and movement can loosen them over time. Strong locks stop this and keep things working.

Good connectors often have two types of locks for extra safety. These locks stop accidental disconnections. For example, crimp connectors with strong cable grips last longer. Secure locks are key for stable connections in tough car conditions.

Reliability and Care of Car Connectors

How Often They’re Used and Wear Over Time

Car connectors wear out with frequent use. Problems like loose wires or weaker systems can happen. Many things cause this wear:

Water and road salt can rust wires and parts.

Accidents might break connectors or uncover wires.

Picking strong connectors lowers these risks. Choose ones made for heavy use without losing strength. Checking them often helps find problems early and avoids big repairs.

Staying Strong During Shaking and Movement

Driving on bumpy roads can loosen connectors. Even tiny movements, like 2 to 6 microns, can hurt connections. This can make systems work poorly or even fail.

To keep them steady, pick connectors with strong locks and tough builds. These features stop shaking from causing problems. Coated connectors that resist rust and wear handle shaking better. This keeps your car working well in rough conditions.

Easy to Check and Replace

Checking and changing connectors should be simple and quick. Small connectors that fit well make them easier to reach. Good-quality connectors built to last are easier to inspect.

When replacing, flexible designs are helpful. Connectors that fit many wire sizes work across different systems. This makes switching them faster and easier. Choosing connectors like this makes maintenance smoother and keeps your car reliable.

Useful Tips for Choosing a Connector

Picking the Right Connector for Your Car

Choose a connector that fits your car's needs. Think about size and how much power it can handle. Small connectors that handle high power work well in modern cars. Pick connectors that fit different wire sizes for more uses. This makes them useful for many car systems.

Performance is also very important. Reliable connectors that meet car maker standards work better. Check how much current and voltage they can handle to avoid problems. For cars with complex systems, connectors with more pins improve signals.

Think about the environment too. Sealed connectors keep out dust and water. Unsealed ones are easier to access. Use connectors made from strong materials like copper or brass. These last longer and work better.

Choosing Trusted Brands and Standards

Good brands make connectors you can trust. They follow safety rules and last a long time. These brands make connectors for many uses, so they fit well.

Look for connectors tested for tough conditions. For example, tests check how they handle heat, dust, and shaking. The table below shows what these tests mean:

Test Type | What It Checks |

|---|---|

Temperature (T1-T5) | Handles hot and cold, T5 is the toughest. |

Seal (S1-S3) | Blocks dust and water, S3 is the best. |

Vibration (V1-V5) | Stays strong during shaking, V5 is for rough conditions. |

Standards like ISO 26262 make sure connectors are safe and reliable. Picking connectors that meet these rules helps your car work well.

When to Ask for Expert Help

Choosing the right connector can be tricky. If you're unsure, ask an expert for help. They can find connectors that fit your car perfectly. Experts also make sure connectors are installed correctly. This avoids future problems.

Experts are very helpful for advanced systems like car screens or fast data connections. These need special connectors to work right. Getting advice keeps your car safe and running smoothly.

Picking the right car connectors keeps your car working well. Look for small size, good power handling, and flexibility. Strong connectors last longer and stop rust from forming. Using tough materials makes them reliable and lowers repair costs. Choose wisely for better performance and fewer problems over time.

FAQ

What matters most when picking a vehicle connector?

Make sure it matches your car's electrical system. This helps it handle voltage, current, and work well in all conditions.

How can I tell if a connector handles tough conditions?

Look at the IP rating. Higher numbers, like IP67, mean better protection from dust and water. Choose materials that resist heat, moisture, and rust.

Can I put in vehicle connectors myself?

You can, but only if you know how and have the tools. For tricky systems, ask an expert to install it right and avoid problems later.

See Also

Enhancing Automotive Data Flow With Superior Connectors And Cables

Boosting Performance Through HFM Connectors In Vehicles

Improving Data Transfer: Why High-Speed Connectors Matter