Expert Tips on Choosing Vehicle Cables for Custom Applications

Choosing the right vehicle cable is crucial. It impacts the efficiency and safety of your project. A quality vehicle cable ensures that your project requirements are fulfilled, whether that involves fast data transmission or robust performance. Custom cable services offer tailored options, allowing you to obtain cables in the exact length you need. Even minor errors can lead to issues, with potential failures ranging from *0.7 to 2 per 100 miles each year*. Always prioritize quality and precision when selecting vehicle cables.

Key Takeaways

Understand your project's specific needs to choose the right vehicle cables, ensuring optimal performance and longevity.

Consider electrical factors like voltage, current, and signal clarity to prevent overheating and maintain clear communication.

Select the appropriate wire type and size, balancing power capacity and safety to avoid overheating and ensure efficient operation.

Choose high-quality covering materials that can withstand environmental challenges such as heat, chemicals, and physical wear.

Ensure connectors are compatible with your cables and project requirements, focusing on strength, ease of use, and cost-effectiveness.

Follow industry standards like SAE and ISO to guarantee safety and reliability in your custom cable designs.

Avoid common mistakes by planning for environmental conditions, future upgrades, and conducting thorough testing to ensure cable integrity.

Knowing What You Need

When picking custom cables, know what you need. This makes sure cables work well and last long.

Electrical Things to Think About

Voltage and Current

Check the voltage and current of cables. These show how much power they can handle. Right ratings stop cables from getting too hot or breaking.

Keeping Signals Clear

Good signal quality is important. Use proper covers to cut noise and stop problems. This keeps signals clear, which is very important in cars.

Physical Things to Think About

Bending and Strength

Cables need to bend without breaking. Check how flexible they are. Good cables last long even when bent a lot.

Shaking and Wearing Out

Car cables face shaking and rubbing. Pick strong materials to stop damage. This helps cables last longer and work well.

Environment Things to Think About

Hot and Cold

Cables must handle hot and cold. Good covers keep them safe from heat and cold.

Chemicals and Water

Cables meet chemicals and water. Pick materials that don’t rust or break. Good covers make cables strong and last long.

By knowing these needs, you pick cables that work best. This keeps wires working well and signals clear.

Picking the Right Wire Type and Size

Choosing the right wire type and size is important. It makes sure cables work well and are safe in cars. Think about different things to choose wisely.

Wire Thickness and Power

Picking the Right Wire Size

Choosing the right wire size is key. Wire thickness shows how much power it can carry. Thick wires are for power, thin ones for signals. This stops signal problems. Copper wires need to be less thick than aluminum ones. Copper is better at carrying power. Always match wire size to what your project needs.

Balancing Work and Safety

Balancing work and safety is important. Make sure wires handle power without getting too hot. Thin wires can overheat and break. Thick wires cost more and are hard to use. Find the right size for good work and safety.

Wire Type Choices

Stranded vs. Solid Wire

Think about where you use the wire. Solid wires carry more power but break easily. They are good when wires don't move. Stranded wires handle heat and bend better. Use them when wires need to move a lot.

Special Wires for Certain Uses

Special wires are made for certain uses. Some have covers that stop chemicals and water. Others handle very hot or cold places. Know what your project needs to pick the right wire. This makes sure wires last and work well.

By picking the right wire type and size, you make cables work better and last longer. This helps your car projects work well.

Covering and Protecting Materials

When picking car cables, look at covering and protecting materials. These are important for keeping your car safe and working well.

Picking Covering Material

Choosing the right covering is key for long-lasting and good cables. Different coverings have special benefits:

PVC, Teflon, and others

PVC (Polyvinyl Chloride): This is popular because it's cheap and bends easily. It keeps cables safe from water and chemicals.

Teflon (PTFE): Teflon handles heat well and fights chemicals. It's great for tough places where cables get hot.

Other Choices: Silicone and rubber are also good covers. They bend and last long, fitting many car uses.

Things that affect covering choice

Many things affect what covering you pick:

Heat Handling: Pick covers that can take the heat in your car.

Chemical Fighting: Make sure covers don't get hurt by chemicals or water.

Strong and Tough: Choose covers that can handle bumps and scratches.

"Good covering materials are needed in car cables for heat handling, chemical fighting, strength, and keeping electricity safe."

Protecting Methods

Protecting is key for keeping signals clear in car cables. It stops bad signals and keeps data moving well.

Types of protecting (foil, braid)

Foil Protecting: Uses a thin metal layer to stop bad signals. It's light and covers well, good for high signals.

Braid Protecting: Made of woven metal strands, it's strong and bends well. It's good where cables shake and move.

Why protecting stops bad signals

Protecting is important to stop bad signals. As cars get smarter with sensors, keeping data safe from bad signals is key. Good protecting makes sure cables send clear signals.

By picking the right covering and protecting materials, you make car cables work better and last longer. This care makes sure your car projects are safe and work well.

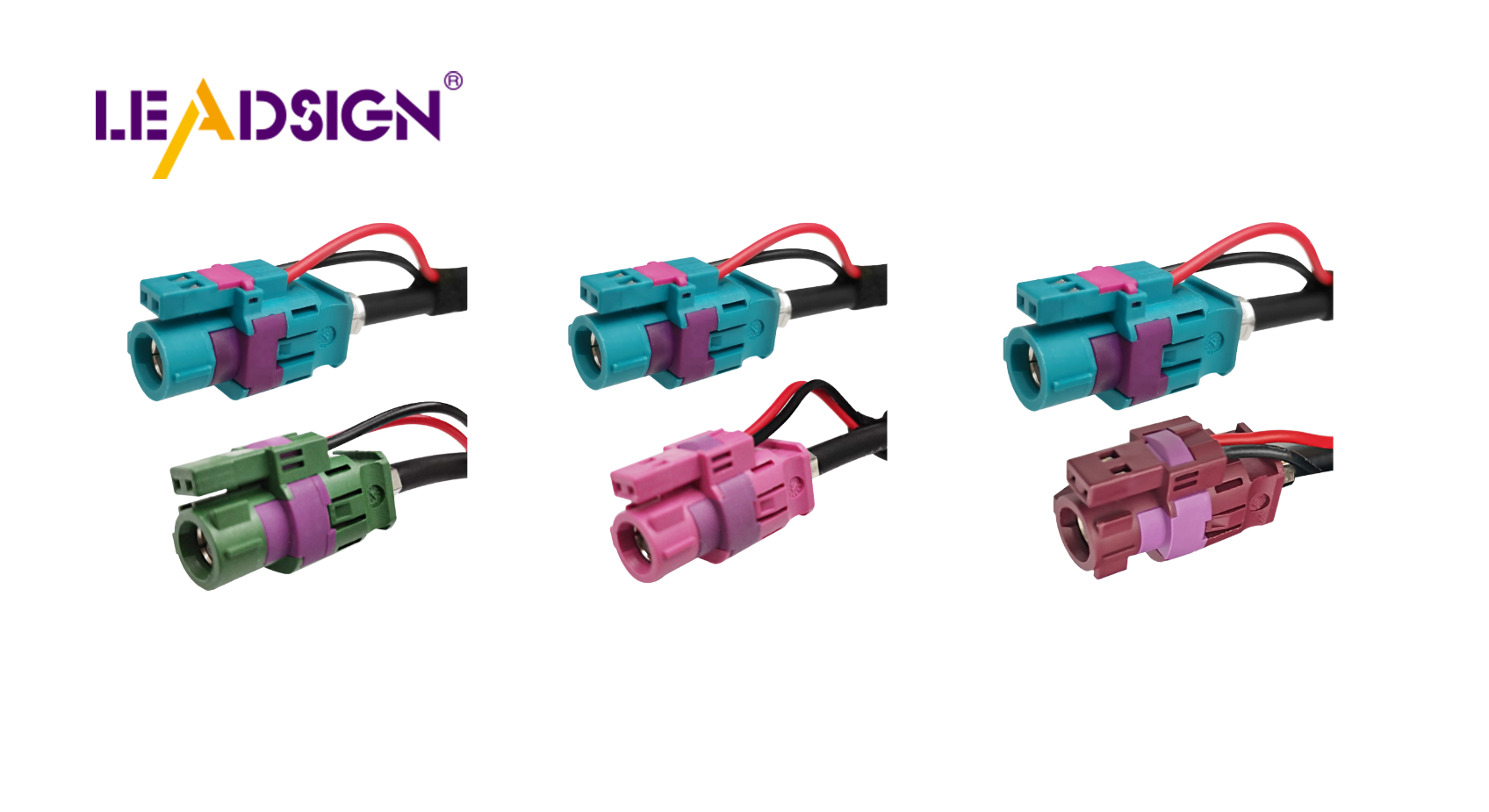

Picking Connectors for Custom Cables

Choosing the right connectors is very important. They help cables work well and stay connected. Let's see how to pick the best ones.

Types of Connectors

Picking the right connector type is key. Here are some things to think about:

How to Pick Connectors

Project Needs: Know what your project needs. Different jobs need different connectors. For example, car projects need connectors that handle shaking and heat.

Strongness: Pick connectors made from good stuff. This helps them last in tough places.

Easy to Use: Choose connectors that are simple to put on and take off. This saves time and stops mistakes.

Cost: Balance good quality with price. Pick connectors that fit your budget but are still good.

"Amphenol is known for making great connectors and cables."

Matching with Wire Types

Make sure connectors fit the wires you use. This keeps connections strong. Think about these:

Wire Size: Match connector size to wire size. This stops problems like getting too hot.

Material Fit: Make sure connector material fits wire material. This stops rust and keeps connections strong.

Keeping Connections Safe

Safe connections are important. Here are ways to do this:

Ways for Good Connections

Right Crimping: Use the right tools. This makes sure wires and connectors stay tight.

Soldering: Sometimes soldering helps make connections stronger.

Testing: Test connections well. This finds weak spots before they cause trouble.

Stopping Connection Problems

To stop problems, follow these tips:

Check Often: Look at connections for damage. Fix problems early.

Protect from Weather: Use covers to keep out water and dust.

By picking the right connectors and keeping them safe, your cables will work better. This makes sure your custom cables do what you need.

Following Industry Rules

Making sure your car cables follow industry rules is very important. It keeps them safe and working well. Following these rules helps avoid problems and makes sure your car projects work right.

Important Rules and Guidelines

Main Rules (SAE, ISO)

When picking cables for cars, know about rules like SAE and ISO. These rules give steps for making and testing car cables. For example, ISO 6722-1 tells what tests cables must pass to be approved. This makes sure cables are strong and bendy in tough places.

"Rules like SAE and ISO are key for keeping car wires safe and working well."

Why Following Rules Matters

Following rules is not just a box to check; it's key for safety and working well. By following these rules, you lower the chance of cable problems, which can be dangerous. Approved cables make you feel good, knowing they work in different situations.

Checking and Approving

How to Follow Rules

To follow rules, test and approve your cables well. This means checking them against rule lists. Tests look at how they handle electricity, strength, and weather. This shows your cables are safe and work well.

Good Things About Approved Cables

Using approved cables has many good points. They pass hard tests to meet rules. This means they work better in car projects. Also, approved cables can make your projects better, giving you an edge.

By focusing on following rules, you make sure your car projects are safe and work well. This focus on quality keeps your work safe and helps car engineering grow.

Common Mistakes to Avoid in Custom Cable Design

When you start a custom cable project, avoid mistakes. This helps cables work well and last long. Here are some mistakes to avoid:

Forgetting About the Environment

Think about where cables will be used. If you don't, cables might break early. For example, if it's very hot or cold, pick materials that can handle it. Water and chemicals need special care too. Wrong materials can rust or break, making cables weak.

Not Planning for the Future

Plan ahead when making cables. If you don't, you might not be able to add new things later. Think about upgrades you might want. By planning, cables can change without starting over. This saves time and money later.

Skipping Tests

Testing is important in cable design. If you skip it, problems might happen. Testing finds weak spots and checks if cables work right. Do tests to check power, strength, and weather handling. This makes sure cables are safe and follow rules.

"Sometimes it's hard to know what's right or wrong. But three questions can help guide you."

By avoiding these mistakes, your cable projects do better. Think about the environment, plan for the future, and always test. These steps make cables work safely and well.

Picking the right car cable is very important. Think about how hot or cold it gets, how much power it can handle, and if it follows the rules. These things make sure your special cables work well and are safe. To use custom cables well, know what your project needs and choose the right materials. Always put safety first and follow the rules to stop problems. This way, your car projects will last longer and work better.

FAQ

What are custom cable assemblies used for in vehicles?

Custom cables are very important in cars. They help with many things, like wiring and car communication. These cables need to be strong, bendy, and handle tough conditions like heat and shaking.

How do I determine the right cable for my custom application?

To pick the right cable, know what your project needs. Think about power, weather, and how much the cable will move. This makes sure the cable works well and safely.

Why is it important to consider environmental factors when selecting vehicle cables?

Things like heat, water, and chemicals can hurt cables. Picking the right materials helps cables stay strong and last long.

What is the difference between stranded and solid wire?

Stranded wires are many small wires twisted together. They bend easily. Solid wires are one thick wire. They carry power better but don't bend well. Choose based on how much the wire needs to move.

How do I ensure my custom cables comply with industry standards?

To make sure cables follow rules, learn about standards like SAE and ISO. Test your cables to see if they meet these rules. This keeps them safe and working well.

What are the benefits of using approved cables?

Approved cables pass hard tests. They work better and are safer. Using them makes you feel sure about your car projects. They also help you do better in the market.

How can I avoid common mistakes in custom cable design?

To avoid mistakes, think about the environment, plan for changes, and test well. This helps cables work well and last long, stopping problems and saving money.

What should I consider when choosing connectors for custom cables?

When picking connectors, think about what your project needs, how strong they are, how easy they are to use, and cost. Make sure they fit the wires you use to keep connections strong.

Why is testing important in custom cable design?

Testing finds weak spots and checks if cables work right. It makes sure cables are safe, strong, and follow rules.

How can I plan for future expansion in my custom cable design?

To plan for changes, think about what you might add later. Make cables that can change easily. This saves time and money later.

See Also

Maximizing Automotive Data Flow With Innovative Connectors

Boosting Data Transfer: Why High-Speed Connectors Matter

Improving Automotive Data Flow Using FAKRA PCB Connectors

Benefits of FAKRA PCB Connectors for Automotive Use

Understanding the Advantages of Fakra Connectors in Vehicles