Choosing the Right Wire Connector Types for Cars

Selecting the appropriate wire connector types for automotive wire is crucial for ensuring safety and efficiency. The auto wire market is expanding at a rate of 5.8% annually, highlighting the significance of reliable connections. Various wire connector types can fail due to heat or electrical issues. Choosing the right automotive wire connectors reduces risks and enhances performance. Understanding these challenges aids in making more informed decisions.

Types of Wire Connectors for Cars

HSD Connectors

Uses in Car Electronics

HSD connectors are important for car electronics. They help send data quickly, which is needed for new cars. Systems like car radios and safety helpers use HSD connectors to work well. These connectors fit different wire sizes, so they can be used in many car parts.

Features and Advantages

HSD connectors have shields to stop interference. This keeps data moving smoothly in cars. They work at high frequencies up to 6 GHz, handling lots of signals. They meet car standards like USCAR, ensuring quality. You can get them in single or double types for different wiring needs.

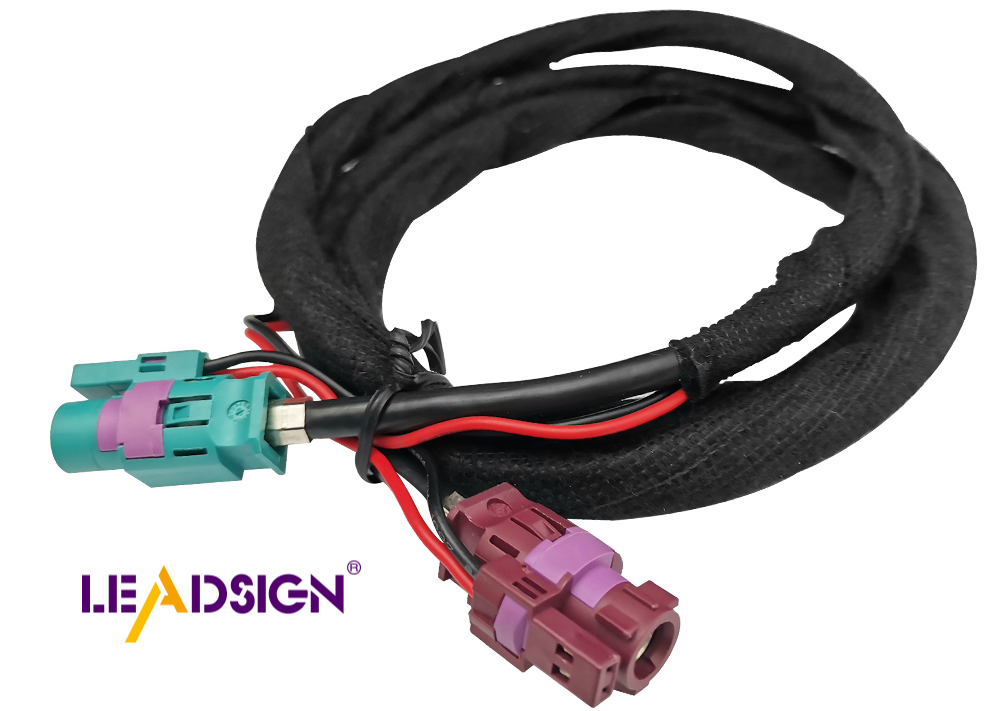

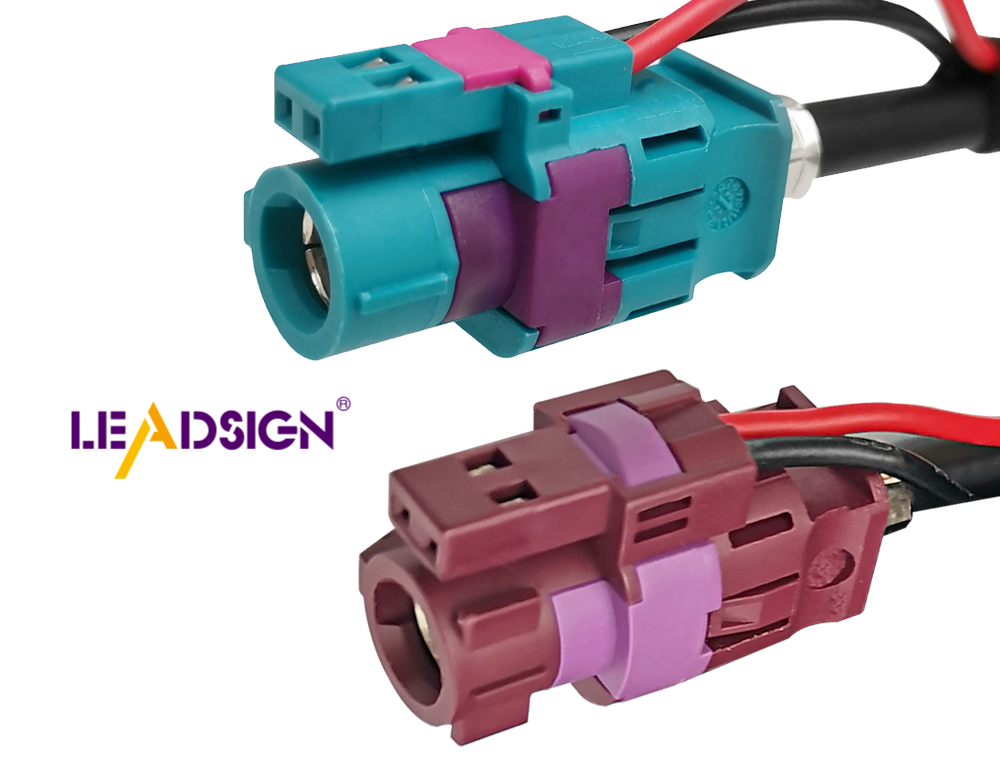

FAKRA Connectors

Role in Car RF Systems

FAKRA connectors are key in car RF systems. They connect audio gear and other electronics safely and securely. This is important to keep signals strong in cars.

Comparing with HSD Connectors

FAKRA and HSD connectors have different strengths. HSD is best for fast data, while FAKRA is great for RF tasks. Each has special uses based on what the car needs.

Other Connector Types

Usual Car Wire Connector Types

There are many wire connector types for cars. Automotive OEM connectors are made just for original makers' vehicles. They ensure the best fit and function using top materials that handle heat and wetness.

Auto Wire Connector Uses

Car wire connectors are used in lights, power setups, and sensors. Each job needs a certain type of connector to be safe and work well. Knowing about these helps pick the right one for each task.

Technical Details and Benefits

Fast Data Transfer

Why It's Important in Cars Today

Fast data transfer is key in today's cars. New systems like entertainment and driver help need quick data. Good data flow makes driving better. Strong connectors keep car parts talking well. Car makers focus on fast data to please buyers.

Following Car Rules

Following car rules makes connectors work well. Rules like USCAR set safety and work standards. Makers follow these to make good products. Well-tested connectors lower failure risks. Steady work keeps cars safe and working right.

Environment Factors

Toughness Against Weather

Toughness against weather is a must for car connectors. Cars face tough things like heat and wetness. Strong connectors handle these well. Good materials stop rust over time. Long-lasting parts make cars safe and reliable.

Fit with Car Systems

Fit with car systems makes sure connectors work right. Connectors must fit into car designs easily. Right fit stops electric problems and system breaks. Makers aim for smooth connector fits. Good connections boost car performance and trust.

Things to Think About When Picking Connectors

Matching with Car Systems

Making Sure They Fit and Work Right

Picking the right wire connectors helps them fit and work well in cars. Each connector type should match what the car needs. The right fit stops electric problems and system issues. Makers make connectors to fit into car designs easily. A good fit makes cars work better and last longer.

Stopping Common Fit Problems

To stop fit problems, choose connectors carefully. Different types of connectors can break at different rates. Things like how they're made, heat, number of parts, and how often used matter. Knowing these helps pick the best connectors. Good choices lower the chance of breaking and keep them working long.

Weather Factors

How Heat and Wetness Affect Them

Heat and wetness change how well connectors work. Cars put connectors through tough weather. Hot temps and wetness can cause rust or wear out parts. Strong materials fight these problems well. Picking strong connectors means they last long even in bad weather.

Choosing for Special Situations

Choosing for special situations means knowing weather challenges. Each car part might need different connector rules. Connectors must handle their own tough spots well. For example, engine area ones face more heat. Picking right ones for each spot keeps them safe and working best.

Choosing the right wire connectors for cars is important. The blog talks about HSD and FAKRA connectors. It also mentions technical details and weather effects. Picking the right connector helps it fit well with car systems. It should also be strong against weather like rain or heat. Good choices make cars safe and work better. Knowing what each car part needs helps in picking the best connector. Strong connections help cars last longer and run smoothly.

See Also

Enhancing Automotive Connectivity with FAKRA Connectors in Modern Cars

The Significance of FAKRA Connectors in Auto Industry Uses

Fakra Connectors: Vital Components in Automotive Sector

Benefits of HFM Connectors for Auto Sector Applications

Maximizing Auto Data Transfer: Cutting-Edge Connectors and Cables